Overlapped Surfaces

To maximize the protection provided by galvanizing steel, design considerations should be taken into account. When the decision is made to hot-dip galvanize, the design engineer should ensure that the pieces can be suitably fabricated for highest-quality galvanizing.

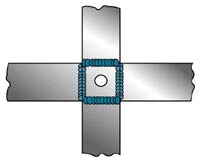

Many fabrications lend themselves well to the galvanizing process, including those that incorporate overlapping and contacting surfaces.

It is important to properly vent overlapping and contacting surfaces to prevent trapped moisture or gas from flashing to steam, which may result in localized uncoated surfaces. Additionally, pressure increases resulting from trapped moisture flashing to steam could possibly rupture the fabrication.

It is important to consult with your galvanizer before fabricating any piece that will include overlapping surfaces. The galvanizer's experience may greatly assist in deciding between a completely seal-welded joint and a skip-welded joint.

Cleaning solutions used in the galvanizing process can become trapped between overlapping and contacting surfaces. Upon immersion into the galvanizing bath at temperatures of more than 800 F (430 C), this moisture is converted to superheated steam that can create internal pressures greater than 3600 psi (25 MPa).

To minimize the possibility of this occurrence, consider the following:

- Seal-welding ensures that cleaning solutions cannot become trapped in the weld area; if skip-welding is used, a gap of at least 3/32" (2.5 mm) must be provided.

- Cleaning solution salts can be retained in tight areas because they cannot be adequately rinsed; the galvanized coating may be of good quality in adjacent areas, but humidity encountered weeks or even months later may wet these acid salts, causing staining of the surrounding galvanized coating.

- When overlapping or contacting surfaces cannot be avoided and are 3/32" (2.5 mm) or less, all edges should be completely seal-welded; zinc's viscosity prevents it from entering any space tighter than 3/32" (2.5 mm).

- There should be vent holes through one or both surfaces into the overlapped area (see tables).

Vent Holes for Overlapped Areas in Steel 1/2" [1.25 cm] Thick or Less

| Overlapped Area in 2 (cm2) | Vent Holes | Unwelded Area |

|---|---|---|

| <16[<103 ] | none | none |

| > 16 and <64 [> 103 & <413] | 3/8" [1 cm] | 1" [2.5 cm] |

| > 64 and <400 [> 413 & <2580] | 1/2" [1.25 cm] | 2" [5 cm] |

| each increment of 400 [2580] | 3/4" [2 cm] | 4" [10 cm] |

Vent Holes for Overlapped Areas in Steel Thicker Than 1/2 [1.25 cm]

| Overlapped Area in2 (cm2) | Vent Holes | Unwelded Area |

|---|---|---|

| <16[<103] | none | none |

| > 16 & <64 [> 103 and <413] | none | none |

| > 64 & <400 [> 413and <2580] | 1/2" [1.25 cm] | 2" [5 cm] |

| each increment of 400 [2580] | 3/4" [2 cm] | 4" [10 cm] |