Tapping Threads

Because hot-dip galvanizing is a coating of corrosion-inhibiting, highly abrasion-resistant zinc on bare steel, the original steel becomes slightly thicker. When talking about tapped holes and fasteners, the increased thickness is important.

In consideration of the added thickness, holes need to be overtapped (enlarged) in order to accommodate the increased size of the fastener to be inserted. While chasing or retapping the nuts after galvanizing results in an uncoated female thread, the zinc coating on the engaged male thread will protect both components from corrosion. For economy, nuts are usually galvanized as blanks and the threads tapped oversize after galvanizing.

Tapping of all holes after galvanizing is recommended to eliminate double-tapping costs and the possibility of cross-threading. If, after galvanizing, the hole is still not large enough, it can be chased or retapped. Chasing or retapping will not necessitate regalvanizing. Because of the zinc coatings cathodic properties, the coating on the mating fastener will protect chased or retapped nuts.

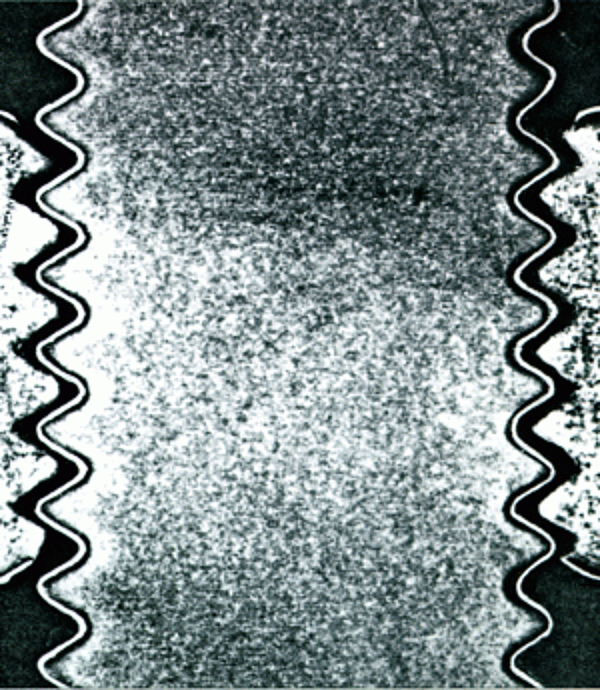

To permit hand-assembly after the addition of zinc to the male thread of the mating part, the female threads pitch diameter should be increased.