Moving Parts

During the galvanizing process, steel is immersed in molten zinc, forming a metallurgically bonded, corrosion-inhibiting coating. Upon removal from the kettle, the once-molten zinc metal will solidify. As a result, the possibility exists for moving parts, such as drop-handles, shackles, shafts and hinges, to freeze together.

Best practice indicates that galvanizing prior to assembly will ensure that moving parts full range of motion is maintained. If moving parts must be galvanized after assembly, increased radial clearance should be incorporated into the design.

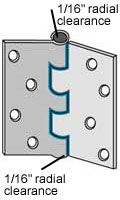

All hinges to be galvanized should be of the loose-pin type.

In order to allow for full range of motion when galvanizing moving parts, consider the following:

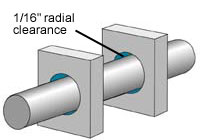

- When a galvanized assembly incorporates moving parts (such as drop-handles, shackles, and shafts), a radial clearance of not less than 1/16 (1.5 mm) is suggested to ensure full freedom of movement.

- After hinges are galvanized, it is recommended that an undersized pin be used to account for the zinc coating. If desired, hinge pinholes may be reamed 1/32 (0.8 mm) after galvanizing to permit the use of regular-sized pins.

- If the galvanizing process freezes the moving parts, they can be reheated to allow them to work freely. Although reheating may cause localized discoloration of the galvanized coating, this discoloration will not diminish the corrosion prevention

For optimum performance, almost all assemblies with moving parts are better assembled after galvanizing.