Tubular Fabrications

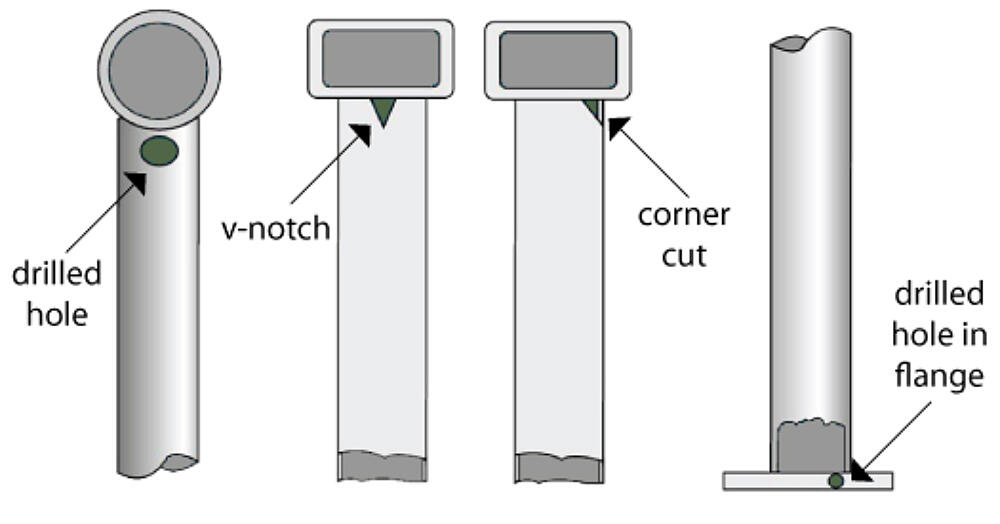

All tubular fabrications and hollow structurals require proper venting and drainage for successful galvanizing. Various methods of venting are acceptable, as seen in this example:

- Galvanizers need to be able to visually confirm and inspect venting in complicated pipe assemblies, such as handrails. Most galvanizers will hesitate to process assemblies unless they can verify adequate venting on the outside.

- Base-plates and end-plates must be designed to facilitate venting and draining. Fully cutting the plate provides minimum obstruction to a full, free flow into and out of the pipe. Since this is not always possible, using vent holes in the plate often provides the solution.

- It is recommended tubular structures be completely submerged in one dip in the galvanizing kettle to minimize potential internal coating problems, which, because of the size and shape of the item, may be difficult to discover during inspection.