Food & Agriculture

With a daily grind riddled with forklifts, pallets, chemicals, wash-downs, and moisture, food and beverage processing facilities are some of the toughest, most corrosive environments imaginable. Similarly, the agriculture industry has a number of buildings, equipment, and other steel items used outdoors or constantly exposed to the elements. Hot-dip galvanized steel provides the right mix of resilience and toughness to keep steel corrosion-free for decades.

Both the food processing and agriculture industries are cost competitive. Any opportunity to decrease operating costs can lead to an advantage in the market place and higher profit margins. Galvanized steel's maintenance-free longevity translates to huge savings in both industries.

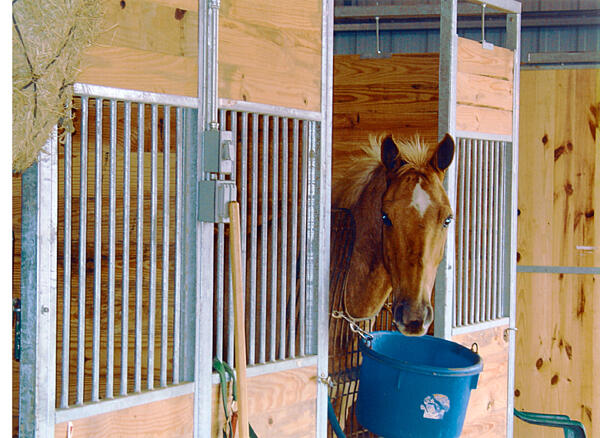

Often the agriculture business is unforgiving, as crops must be watched and animals must be tended throughout the year and outside of a nine-to-five schedule. Hot-dip galvanized steel provides maintenance-free corrosion protection around the clock for decades. Whether fencing systems exposed to animal waste and wear and tear from chewing, rubbing, and other behaviors, or grain storage facilities and equipment, the natural zinc coating is both durable and safe. Most farmers and agri-business have little time or money to waste on upkeep of structures or equipment. Because galvanizing provides substantial maintenance time and cost savings, it is widely accepted as one of the best forms of corrosion protection in the agriculture industry.

In the food processing industry, hot-dip galvanized steel is also a mainstay. Utilized in conveyor castings, chains, and supports, as well as storage racks and shelves due to its limited maintenance and ease of cleaning, hot-dip galvanizing combats corrosion for decades. With rigid regulations for cleanliness, food processing plants are exposed to more than the average share of harsh chemical cleaners and water. The Allen Canning Company uses galvanized steel throughout their building structure because of its durability and resistance to corrosion.

Not only do processing facilities have to worry about chemical corrosion from daily cleanings, they also must worry about the higher levels of condensation present in cooling facilities. Galvanized steel products have performed uninterrupted for decades in chilly, corrosive environments, even in the frigid climates of places like the Arctic Circle, proving shelving and structural galvanized steel utilized in refrigerated facilities will be able to stand the test of time. Though the temperature of the air can have a significant effect on the corrosion rate of some materials, galvanized steel does not show significant differences at either very low temperatures (below -40 F) or at very high temperatures (above 150 F and below 390 F.) The Buffalo Wild Wings in Bradley, Illinois as well as other locations across the country use galvanized racks in their freezers and back rooms to store food preparation items and equipment.

Corrosion creates an unsafe and dangerous environment for food handling, so the durability of galvanized steel means there will be no fear of contamination for years to come. Rusted storage structures risk contaminating the food as well as creating a dangerous work environment for facility employees. As rust gnaws at steel, the metal becomes increasingly weak, and if one support or piece of the structure is weakened, the whole form is at risk of failure. Utilizing a tough galvanized coating will protect the structures within a facility, while the safe, natural zinc poses no threat to the products transported through the plant.

The following list of applications provides proof of acceptance of galvanizing in the agricultural and food processing industries. All items are taken from known, successful, cost-effective applications. For more examples of galvanized steel use in food & agriculture industries, visit the AGA Project Gallery.

| Building Structures | Conveyor Casing | Conveyors | Electrical Conduits |

| Equipment Hooks | Equipment Supports | Farm Implements | Farm Buildings |

| Fasteners | Feeding Equipment | Fencing | Gates |

| Grain Hoppers | Grain Conveyors | Grain-mixing Equipment | Grain Elevators |

| Grain-drying Equipment | Grating | Growing Racks | High-speed Freezing Equipment |

| Irrigation Equipment | Light Poles | Panels | Power Take-Off Shifts |

| Pre-engineered Buildings | Processing Equipment | Railings | Refrigeration Brackets |

| Refrigeration Shelves | Side Frames | Silo Extraction Equipment | Slotted Floors |

| Stanchions | Steel Bands | Storage Racks | Substation Structures |

| Supporting Structures | Tractor Parts | Tractor Wheel Hubs | Substation Structures |

| Transmission Plates | Vegetable Washing Machine | Veterinary Equipment | Waste Conveyor Systems |

| Waste-handling Equipment Pups | Watering Troughs | Window Frames |

Food & Agriculture Case Study

Lazy Magnolia Brewery- Kiln, MS; 2014

The Lazy Magnolia Brewery is Mississippi's oldest packaging brewery, and the first one since prohibition was enacted in 1907. The brewery has been offering locally brewed beer to Mississippians since it was founded in 2003 when the owners bought a home brew kit. The first batches were produced by 2005 but progress was interrupted by hurricane Katrina, losing 80% of their business. The brewery received a grant from the US Department of Agriculture and began an expansion occurring over a four year period.

Lazy Magnolia is dedicated to providing the best possible products through tireless efforts, superior motivation and Southern Heritage. With solid and sound business decisions the company has expanded into 14 states with more to come in the near future. HDG steel played a major role in the recent expansion of the brewery required to meet the increase in demand. This kind of ingenuity helped the owners realized it was the right time, right place, and right product for a growing business in the south.