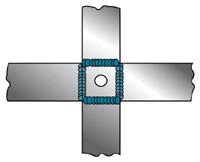

Overlapping Areas

What considerations should I keep in mind when designing steel fabrications to be galvanized?

As the name implies, steel is dipped into a bath of molten zinc during the hot-dip galvanizing process. While the process is inherently simple, hot-dip galvanizing is different than painting or other corrosion protection coating systems, and therefore presents unique requirements during the design stage in order to ensure a high quality zinc coating. ASTM A385, Standard Practice for Providing High-Quality Zinc Coatings(Hot-Dip), specifies design recommendations that should be followed when fabricating steel to be galvanized. There are too many recommendations to be discussed in this issue, so they will be broken up and presented as a series continuing into later issues.

When designing a fabrication to be hot-dip galvanized, best practices say to avoid large overlapping surfaces being welded together. This includes narrow gaps between plates, or back to back channels or plates. However, overlapping surfaces cannot always be avoided and require special venting practices before being dipped in a hot-dip galvanizers kettle.

The gap left between two overlapping surfaces will contain small amounts of air, and perhaps some moisture as well. During the galvanizing process, this entrapped air and moisture will become heated to the galvanizing temperature with the rest of the fabrication (around 830° F). This will cause a rapid expansion of the entrapped air and/or moisture, resulting in a possible blowout of the weld. This blowout will obviously affect the integrity of the fabrication and may also cause a dangerous situation for the galvanizer present during this violent event. In order to avoid this, one may simply avoid large overlapping areas while designing a fabrication, or proper venting procedures must be followed. Venting of overlapped parts may be achieved through stitch welding procedures or by adding vent holes into the overlapping pieces themselves.

Stitch Welding

If the gap created by the overlapping pieces is wider than 3/32, the designer or fabricator has the option to use a stitch weld to vent the gap. The viscosity of molten zinc allows it to enter gaps in fabrications that are 3/32 or greater. If, however, there is a gap smaller than that, moisture and chemicals from the cleaning process prior to galvanizing will enter the gap and it will be left uncoated after dipping in the bath. This will lead to staining of the galvanized coating around the gap due to oxidizing of the uncoated steel.

Using a stitch weld instead of a vent hole has the advantage of not needing to go through the fabrication step of adding extra vent holes into steel pieces. However this method is not appropriate for gaps less than 3/32. It may also be inappropriate for pieces requiring a stronger weld. See the table below for information on the amount of area to be left un-welded when using this technique.

RECOMMEND LENGTH OF UN-WELDED AREA

| Overlapped Area (in2) | Steel ½ Thick or Less (in) | Steel Thicker Than ½ (in) |

|---|---|---|

| <16 | None | None |

| >16 and <64 | 1 | None |

| >64 and <400 | 2 | 2 |

| Each increment of 400 | 4 | 4 |

Vent Holes

Designers and fabricators also have the choice to use vent holes rather than stitch welds to properly vent an overlapping area. This option is always available, but it is necessary when the gap created by the overlapping parts is less than 3/32, or when a full seam weld is required for structural concerns. The vent holes may be added to one or both of the overlapping pieces. As the area of the overlapping pieces becomes greater, so too will the size of the necessary vent hole. The table below gives information on the size of the vent hole needed.

DIAMETER OF VENT HOLES NEEDED

| Overlapped Area (in2) | Steel ½ Thick or Less (in) | Steel Thicker Than ½ (in) |

|---|---|---|

| <16 | None | None |

| >16 and <64 | 3/8 | None |

| >64 and <400 | ½ | 1/2 |

| Each increment of 400 | ¾ | ¾ |

Conclusion

While it may be best to avoid large overlapping areas in a fabrication that is to be hot-dip galvanized, proper venting of the overlapping area will avoid concerns of both safety and corrosion. Whether the stitch weld method or vent hole method is used, there is no substitute for good communication with your galvanizer. They will be your most valuable resource for all design concerns.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.