Life-Cycle Cost Calculator

The estimated annual cost of corrosion is a staggering 3% of the US GDP and the life-cycle cost of corrosion maintenance for any one project is two to five times the initial cost, making the selection of a corrosion protection system for your project critical. However, too often the only cost analysis performed at the inception of a project is initial cost. The Life-Cycle Cost Calculator (LCCC) uses your specific imputed project data to develop and compare the initial and total cost (initial + maintenance) of more than 30 steel corrosion protection systems (paint, metallizing) to hot-dip galvanizing.

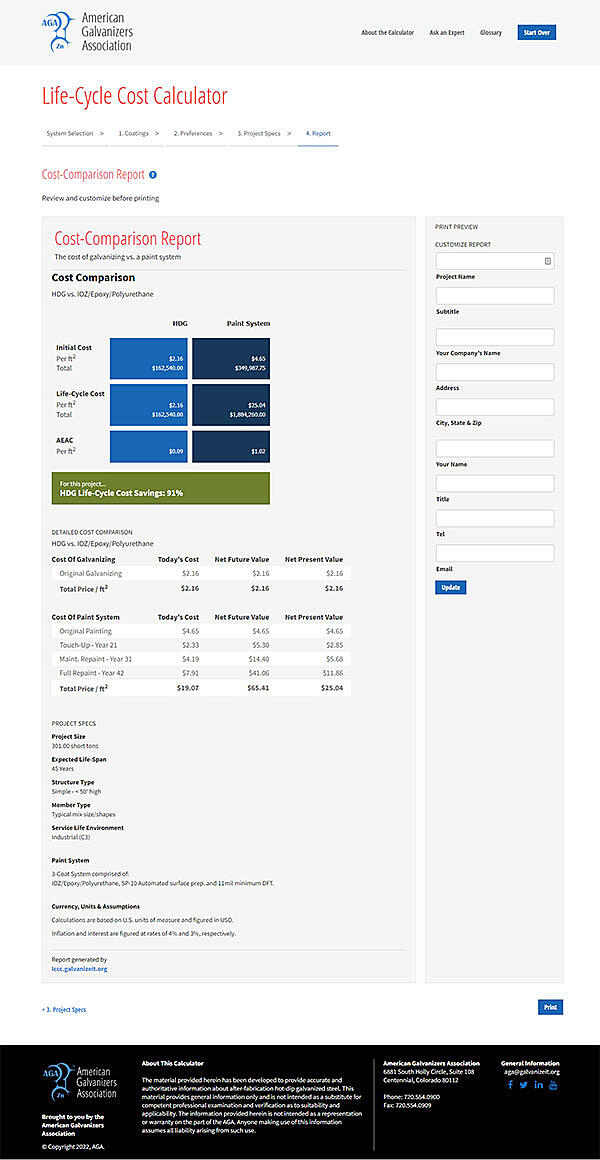

Once you launch the calculator, you will be prompted to enter specific details about your project such as the total tonnage or surface area, coating type, surface preparation required, atmospheric exposure condition (rural, industrial, coastal), and desired service life. The LCCC will then run a complex calculation based on established financial industry equations to determine the value of money over time including net present value (NPV) and net future value (NFV). The LCCC automates the exact equations from the recently released specification ASTM A 1068, Practice for Life-Cycle Cost Analysis of Corrosion Protection Systems on Iron and Steel Products.

After you complete the three quick input screens with project details, the Life-Cycle Cost Calculator will generate a customized, printable report detailing the initial and life-cycle cost of hot-dip galvanizing compared to the system you selected.

Launch the Galvanizing Cost Calculator

Data Sources

TA Tator, Inc., a consultant to the paint industry, conducts a survey of paint manufacturers biennially. The current data is based on the results of the 2021 Expected Service Life and Cost Considerations for Maintenance and New Construction Protective Coating Work (Helsel, Lanterman).

Durability data, i.e. time to maintenance and time to full repaint in the paper is based on actual in-field performance.

All the financial equations used in the calculator are the same as those provided in the specification ASTM A1068-10 Standard Practice for Life-Cycle Cost Analysis of Corrosion Protection Systems on Iron and Steel Products.

- Paint system costs (including surface preparation) and practical maintenance times: J. Helsel and R. Lanterman. (2021). Expected Service Life and Cost Considerations for Maintenance and New Construction Protective Coating Work. KTA-Tator, Inc.

- Metallizing costs (including surface preparation) and practical maintenance times: J. Helsel and R. Lanterman. (2021). Expected Service Life and Cost Considerations for Maintenance and New Construction Protective Coating Work. KTA-Tator, Inc.

- Hot-Dip Galvanizing costs: American Galvanizers Association National Survey (2021)

- Hot-Dip Galvanizing time to first maintenance (corrosion rates): Average values from Table 1 of ISO 14713-1:2017, Zinc coatings — Guidelines and recommendations for the protection against corrosion of iron and steel in structures — Part 1: General principles of design and corrosion resistance.

Paint system service environments: Table 1 of ISO 12944-2:2017, Paints and varnishes — Corrosion protection of steel structures by protective paint systems (Part 2: Classification of environments). - Hot-Dip Galvanizing service environments: Table C.1 of ISO 9223:2012, Corrosion of metals and alloys — Corrosivity of atmospheres — Classification, determination and estimation.