Bridge & Highway

Connecting the width and breadth of our nation, transportation elements such as bridges, guardrail, mechanically stabilized earth, and reinforcing steel knit together communities across the country. This transportation system is also a key facilitator of economic movement, sending goods and people to and fro to conduct business and stimulate the economy.

As the government commits large sums of taxpayer dollars to develop and upkeep these critical transportation systems, protecting this investment from deterioration should be of the utmost importance. Hot-dip galvanized steel works to prevent such costly and damaging corrosion and preserve our nation's infrastructure for future generations.

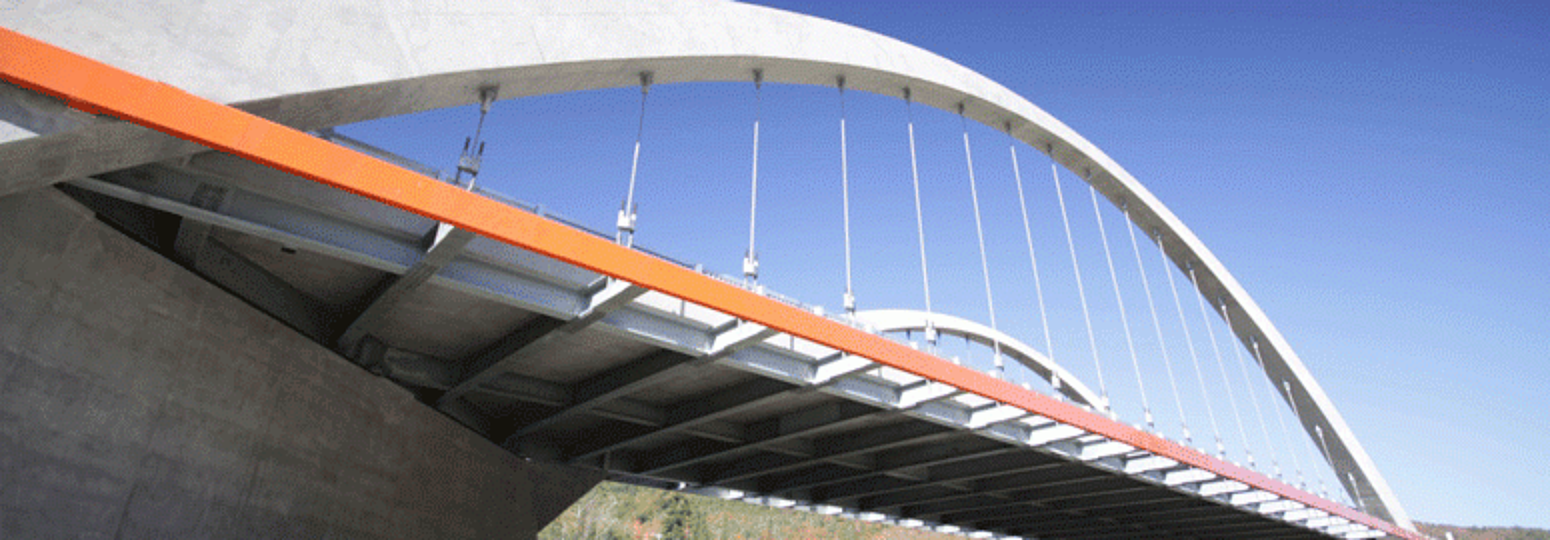

Steel is a principal construction material in the bridge market due to its unmatched strength-to-weight ratio. Because steel used in the bridge market is constantly exposed to weather, deicing chemicals, and atmospheric pollutants, it must be protected. Hot-dip galvanizing has been successfully used to combat corrosion in bridges since the 1800s. Whether the superstructure of a traffic bridge, the backbone of a pedestrian crossing, or a beautiful truss igniting the landscape; hot-dip galvanized steel provides long-lasting maintenance-free protection for decades.

In the last few years, there has been renewed interest in the steel bridge market. The reason for that is first and foremost the proven history of long-standing steel bridges throughout North America. Furthermore, there are a number of key groups researching and promoting the use of steel in bridges. The Short Span Steel Bridge Alliance (SSSBA) , for instance, is promoting the economic benefits of building steel bridges between 40 and 140 feet. The SSSBA has developed an online tool eSpan 140 to facilitate the design of short span steel bridges, which coupled with economic case studies is beginning to drive more specifications to steel.

However, bridges are not the only place hot-dip galvanized steel is used in the infrastructure. Galvanized steel is commonly used in a number of other highway products such as guardrail, light poles, sign posts, mechanically stabilized earth systems, and even the hidden reinforcing steel. Galvanizing has proven its ability to successfully protect steel from corrosion in all of these applications. Though hot-dip galvanized steel has always provided superior life-cycle costs because it is virtually maintenance free, in recent years, the initial cost of HDG is also competitive and even less expensive. This cost savings both initially and over the life of the project along with its proven performance has led specifiers to utilize hot-dip galvanized steel in the highway products market more than ever before.

Galvanizing is the workhorse coating resisting corrosion in many bridge and highway elements. Here is a list of real-life proven applications in use throughout North America.

| Anchor Bolts | Light Poles | Access Doors | Complete Bailey Bridge Structures |

| Anti-suicide Rail | Pipe Supports | Bin-Type Retain walls | Signal Supports |

| Base Plates | Pipe Railing | Jersey Barrier Embedments | Temporary Bridges |

| Bolts | Piping | Inspection Catwalks | Trench Drains |

| Box Rail | Pot Bearings | Drainage Supports | Breakaways |

| Bridge Rail | Pour-In-Place Forms | Drainage Systems | Culverts |

| Cable Connectors | Reinforcing Splice Clips | Driven Pilings | Guardrail |

| Cross-Bracing | Reinforcing Steel | Fencing | Delineators |

| Curb Angles | Scuppers & Drains | Ground Anchors | Fencing |

| Diaphragms | Shear Studs | Ladders | Insert Modules |

| End Dams | Sign Supports | Pier Pilings | Overhead Sign Support |

| Expansion Dams | Signal Light Poles | Sound Barriers | Pedestrian Overpass Bridge |

| Finger Joint Expansion Dams | Spiral Shear Connectors | Guardrail Posts | Stringers |

| Flooring Grid | Splice Plates | Retaining Walls | Girders |

| Floor Gratings | Steel Divider Barrier | Sheet Piling |

Bridge & Highway Case Study

Bridges of Stark County, Ohio- Galvanized in 1975

In the movie, The Bridges of Madison County the bridges were wooden covered bridges. The Bridges of Stark County Ohio are galvanized bridges and have been for 40 years. In the early 1970s, Rich Larocco was a young bridge engineer for Stark County, just out of college. At that time, 110 of Stark County's bridges were deficient and 50% of the bridge budget was used to repaint bridges. Rich worked with the former owner of the galvanizing facility to change those numbers. Rich decided rather than continue to repaint bridges over and over, he would dismantle the bridge. He had the decks and beams removed. The beams were sandblasted and galvanized. Then the entire 'recycled' bridge was reinstalled. After that they never repainted an old bridge or painted a new bridge, even if the long beams or large trusses had to be progressively dipped in the galvanizing plant. There are 442 Bridges in Stark County, 335 of which are maintained by the county. Many are short span low clearance steel bridges over creeks and streams in rural areas, making an ideal environment for hot-dip galvanized bridges. Stark County Ohio has seen a lifetime of corrosion-free service with hot-dip galvanized bridges. Stark County will continue to benefit from galvanized bridges for lifetimes to come.