2019 Excellence in Hot-Dip Galvanizing Awards Showcase Galvanized Steel's Versatility and Beauty

CENTENNIAL, CO - The American Galvanizers Association (AGA) is pleased to announce the winners of the 2019 Excellence in Hot-Dip Galvanizing Awards. Nearly 100 projects were submitted representing the versatility and beauty of hot-dip galvanizing. A panel of judges made up of architects and engineers judged the projects online to determine the winners. The 2019 winners highlight the need for strength and longevity of hot-dip galvanized steel in the construction market.

The highest honor of the night went to the Whistler/Blackcomb Cloudraker Suspension Bridge in British Columbia, which took home the Most Distinguished award. The 427 foot suspension bridge and 40 foot cantilevered viewing platform sit 7,160 feet above the valley floor, providing visitors with 360 degree views. The process of erecting the bridge was complex and required the use of a special helicopter and crew. This meant the material used needed to withstand manhandling during installation, but with minimal maintenance requirements.

The second most prestigious award of the night, Lifetime Achievement, is presented to projects with a minimum of 15 years in service. The 2019 Lifetime Achievement Award was granted to the Walter Pyramid. Located on Long Beach State University's campus, the Walter Pyramid is a 25 year old landmark and collegiate sports facility. More than 500 tons of hot-dip galvanized steel were used in the construction of the pyramid to protect the structural integrity from the humid California air. According to Mark Zakhour, Construction Services Manager, at Long Beach State University "The galvanized structural configuration has performed flawlessly and there have been no maintenance requirements or operational issues since erection."

In addition to the Walter Pyramid, a few other building structures completed in 2018 were honored. Two high-visibility projects in New York City shared the Building & Architecture award, showcasing hot-dip galvanized steel in an urban environment.

The 53 West 53rd MoMA Tower stands 1,050 feet above midtown adjacent to the Museum of Modern Art (MoMA) and can easily be distinguished from other buildings in the area by its unique façade. A lattice-like pattern weaves across the building giving it personality and increased structural security, something which was of upmost concern to the engineers. Considering the height of the building and location, constant maintenance was not an option. Hot-dip galvanized steel was the perfect choice for its low maintenance, durability and visual appeal for the façade panels of the upper floors. Hot-dip galvanized stel is doing its part to provide stunning, obstructed views of Central Park from this new iconic building.

The second winner in Building & Architecture, the Cornell Tech Bloomberg Center also calls New York City home. Sitting on the southern end of Roosevelt Island, under the Queensboro bridge, the four-story, 160,000 square foot building was to have net-zero energy, which would require a strong and durable support structure. Even with a large budget that would have allowed any corrosion system desired, hot-dip galvanizing was specified for its modern, industrial look, quick turn-around time, and minimal maintenance requirements.

Other projects show a more utilitarian use of hot-dip galvanized steel - proving its versatility. A great example is the U.S. Navy Port Security Barriers which won the Water and Marine category. The Port Security Barrier (PSB) Systems were developed after the attack on the USS Cole in 2000. The PSB can stop boats speeding up to 60 mph and under full power. Given the location and function of the barriers, the US Navy needed a strong material to withstand the harsh sea waters. Hot-dip galvanized steel was the best option to protect our ships and military due to its durability and maintenance-free longevity.

Another hidden, but critical use of hot-dip galvanized steel is in the mining industry as demonstrated by the winner of the Industrial Award. In the Sibanye Stillwater Mining Operations in Nye, Montana, safety is of upmost importance. Thousands of feet underground, blasting through tons of solid rock is an environment only a miner can understand. After each blast, the shafts must be secured with steel wire to protect the teams before continuing. Hot-dip galvanized wire and rock bolts stand up to the blast debris and moisture providing better protection for the workers and less cost for repairs on the protective mesh. Hot-dip galvanized steel is a critical component of ensuring everyone goes home safely every day.

Three projects showing hot-dip galvanized steel can be both practical and visually pleasing were awarded in the Transportation and Bridge & Highway categories. The Transportation Award was given to the Chicago CTA’s 95th Street Red Line Terminal which is an important gateway for the city's South Side and suburbs. The $280 million terminal, which is a vibrant landmark, serves more than 20,000 bus and rail passengers each day. Thanks to hot-dip galvanized steel, the station is not only cost effective and functional, but will be beautifully rust-free for decades to come.

The projects honored in the Bridge & Highway category showcase hot-dip galvanized steel in two very different environments in North America. The New Gouin Bridge in Quebec is a historic crossing between St. Jean and Iberville. In the past, the corssing has been served by both a wooden and concrete bridge, both of which needed continual repair in the harsh climate. With a goal of a longer service life and lower maintenance costs, hot-dip galvanizing was chosen for the rebar and structural steel of the new bridge.

Devastated by Hurricane Maria in 2017, the City of Utuado in Puerto Rico had been left disconnected by flooding and damage from the winds. Reconstruction was an urgent need, but it was also paramount to ensure the new bridges would last in the hot, humid climate. Thanks to the quick action of the bridge manufacturer and galvanizer, and the use of modular design, the first hot-dip galvanized bridge was manufactured and installed in just six weeks, and all new bridges were completed in six months. The galvanized steel bridges not only helped reconnect the communities quickly, but their longevity also ensures the community will stay connected well into the future.

Many specifiers seek out the modern, industrial look of hot-dip galvanized steel; however, some projects call for a softer aesthetic and/or additional corrosion protection. This is often accomplished by using a Duplex System - paint or powder coating over hot-dip galvanized steel. Three of the 2019 Excellence in Hot-Dip Galvanizing Award winners took advantage of this aesthetic enhancement.

The Gathering Place ONEOK Boathouse in Tulsa, OK won the Duplex System award. Gathering Place sits on the shore of the Arkansas River, just minutes from downtown, and is the largest privately funded park in the United States. The three-level, 21,000 square foot ONEOK Boathouse is perched 35 feet above the pond as the centerpiece of the park. Hot-dip galvanized steel was chosen to provide the support for the fiberglass "sail like" panels of the pavilion. The designer insisted on hot-dip galvanizing to ensure durability, but added the paint to match the color of the adjoining sails. Thanks to this forward thinking, the Boathouse will remain a beautiful hub for the community offering offer great views of the park and downtown Tulsa.

The winner of the Recreation & Entertainment category, Roger Williams Park Zoo - Faces of the Rainforest also used a duplex system. Sitting in the heart of the zoo in Providence, Rhode Island the exhibit replicates the look and feel of the Amazon. With animals living in the exhibit and hundreds of visitors passing through daily, not to mention the added challenge of a warm, humid climate inside and the unpredictable New England Climate outside, the architect knew they needed a premium corrosion protection system. The final choice was a duplex system, which not only provided a longer life span, but also a welcoming aesthetic to safely house its residents without disrupting maintenance.

Hot-dip galvanized steel’s rust inhibiting and unique aesthetic often makes it a top choice for artistic projects. However, the 2019 Artistic winner, Giant Squid, opted for the added protection of a duplex system on the 20-foot sculpture. Originally designed for and displayed at Burning Man in the Black Rock Desert, the sculpture now calls the mountains of Aspen, Colorado home. With unpredictable, extreme weather in both those environments, the artist knew they needed a corrosion protection system that would protect the integrity of the art without compromising its appearance, and paint alone was not enough. Thanks to the synergistic effect provided by galvanizing and paint, the Giant Squid will bring a glimpse of the Pacific Ocean to the Rocky Mountains for decades to come.

Hot-dip galvanized steel has a long history in the power industry from generation facilities as well as transmission and distribution structures. As the movement toward clean energy expands, hot-dip galvanized steel remains the material of choice as shown in the Electric, Utility, & Communication category.

This year's winner was focused on sustainability for the Silver Oak Winery. After a devastating wildfire, the owners wanted to rebuild the winery with little to no carbon footprint, including using alternative energy (solar), water reuse systems, and reclaimed building material. More than 60,000 pounds of galvanized steel supports the solar panels installed to power the winery's daily needs - in fact - the panels produce more energy than the winery consumes. Aging is central to the wine-making process, and adding sustainability to their winery's environment ensures a healthier future for all.

The Acorn Infrastructure 100MW HFO Power Plant in Bangladesh took home the International Award. Located on the shores of the Karnaphuli River near the Bay of Bengal the area is known for its harsh climate and unpredictable weather changes. In addition to challenges posed by the weather, the plant is also exposed to pollutants which are a challenge for any coating to survive. The ability of hot-dip galvanizing to coat every inch of the steel, including the interior of hollow sections, ensures the structure will stand up to the adverse conditions, providing the best option for the contractor.

Another area where hot-dip galvanized steel has been used extensively is in industrial environments, as highlighted by the 2019 winners in Food & Agriculture and Original Equipment Manufacturing (OEM) categories. The Imperial Sugar Expansion, winner of the Food & Agriculture Award choose hot-dip galvanizing for the construction of their specialized tanks, supports, handrails and ladders. Imperial Sugar Company is the largest sugar refining organization in the United States. The owners have past experience with hot-dip galvanized steel, and knew it would last for decades without impacting the functionality of plant with costly maintenance.

Dumpsters are another product that take a lot of abuse over their lifespans. Being dragged around, filled and refilled with all sorts of debris and chemicals and constantly sitting out in the elements make them an easy target for damage and corrosion. Because of that, the OEM winner, JJ’s Waste & Recycling chose to galvanize their dumpsters to extend their service life and to increase their value to their customers. As a company that promotes recycling JJ's is very conscious of the environment and the communities in which they serve. Galvanized steel is 100% recyclable which allows JJ's to reduce their carbon footprint and meet their environmental goals.

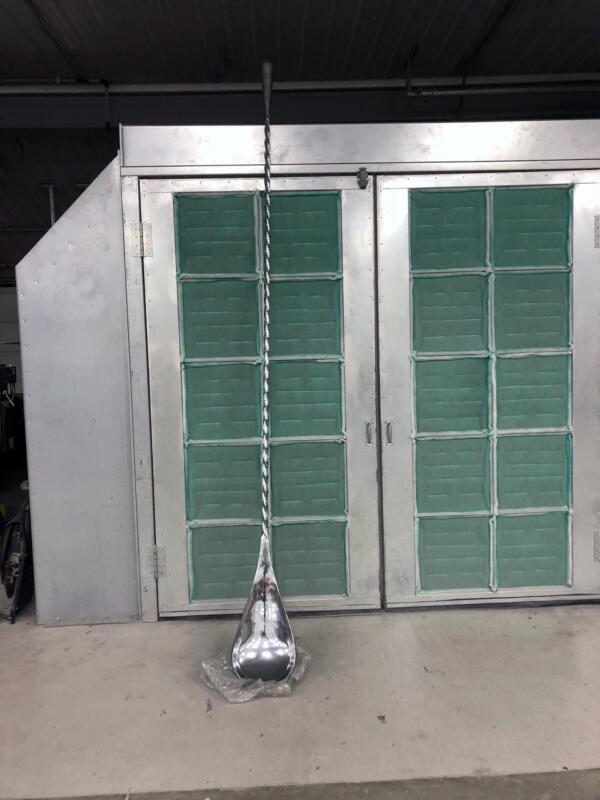

Casey, Illinois is known for being home to a number of world record breaking objects including the world’s largest wind chime and mailbox. With many small towns in the region struggling stay afloat, the town of Casey and Jim Bolin decided to take matters into their own hands and create attractions that would bring people in. Wanting to do their part in helping the community grow and attract visitors the local galvanizer donated a portion of the hot-dip galvanizing for the newest attraction in town and winner of the Civic Contribution category, World's Largest Twizzle Spoon.

With its aesthetic appeal, durability and sustainability hot-dip galvanized steel has proven to be an excellent choice for construction projects of all shapes and sizes. To see more hot-dip galvanized steel projects including other submissions to the 2019 competition and past winners, please visit the AGA Project Gallery.

Complete list of Winners, by category:

| Category | Project | Location | Galvanizer(s) |

| Most Distinguished | Whistler/Blackcomb Cloudraker Suspension Bridge | Surrey, British Columbia | Ebco Metal Finishing LP |

| Lifetime Achievement | Walter Pyramid | Long Beach, California | Valmont Coatings - Calwest Galvanizing |

| Artistic | Giant Squid | Aspen, Colorado | AZZ Galvanizing - Reno |

| Bridge & Highway | New Gouin Bridge | Saint-Jean-Sur-Richelieu, Quebec | Corbec Inc. - Quebec City |

| Bridge & Highway | City of Utuado | Utuado, Puerto Rico | V&S Columbus Galvanizing |

| Building & Architecture | Cornell Tech Bloomberg Center | New York, New York | Corbec Inc. - Quebec City |

| Building & Architecture | 53 West 53rd MoMA Tower | New York, New York | V&S Amboy Galvanizing |

| Civic Contribution | World's Largest Twizzle Spoon | Casey, Illinois | AZZ Galvanizing - Peoria |

| Duplex Systems | Gathering Place ONEOK Boathouse | Tulsa, Oklahoma | Valmont Coatings - Oklahoma Galvanizing |

| Electrical, Utility & Communications | Silver Oak Winery | Healdsburg, California | AZZ Galvanizing - Arizona |

| Food & Agriculture | Imperial Sugar Expansion | Port Wentworth, Georgia | Galvan Industries, Inc. |

| Industrial | Sibanye Stillwater Mining Operations | Nye, Montana | AZZ Galvanizing - Denver AZZ Galvanizing - Goodyear AZ |

| International | Acorn Infrastructure 100MW HFO Power Plant | Chittagong, Bangladesh | LTL Galvanizers (Pvt) Limited |

| Original Equipment Manufacturing | JJ’s Waste & Recycling | Orlando, Florida | Valmont Coatings - Tampa Galvanizing Valmont Coatings - Birmingham Galvanizing |

| Recreation & Entertainment | Roger Williams Park Zoo - Faces of the Rainforest | Providence, Rhode Island | Duncan Galvanizing Corp. |

| Transportation | Chicago CTA’s 95th Street Red Line Terminal | Chicago, Illinois | Valmont Coatings - Empire Galvanizing |

| Water & Marine | U.S. Navy Port Security Barriers | Welch, West Virginia | AZZ Galvanizing - Bristol |