Plugging Holes

During hot-dip galvanizing, steel fabrications are entirely immersed in corrosion-inhibiting molten zinc metal, resulting in unsurpassed corrosion protection of all interior and exterior surfaces. To allow for this thorough coating, holes in fabrications are often required. These holes allow for any or all of the following:

- To facilitate venting and/or drainage,

- To allow for hanging/racking during the galvanizing process

- For structural connection purposes

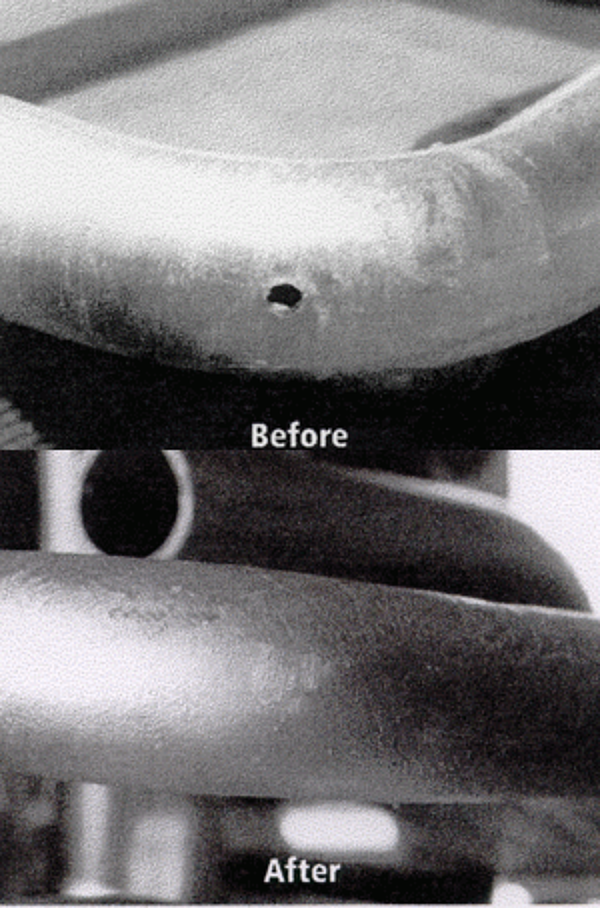

If needed or desired, holes can be plugged after galvanizing. If filler material other than zinc is used (e.g. aluminum), there is a chance of accelerated corrosion in the localized area due to dissimilar metals in contact for hole plugs when located in more aggressive or marine environments.

Consult your galvanizer to determine which filler material is best suited to meet your objectives.

When plugging is required, the fabricator is usually responsible for doing that, but once again, that topic should be discussed in the purchase order to prevent any confusion. Bruce Reichelt Enterprises, located in Oregon, and The Steel Supply Company, located in New York, distribute vent/drain plugs for the galvanizing industry. They supply aluminum vent plugs in sizes ranging from ¼" to 2" in 1/16" increments. Zinc plugs are available from ¼" to 1 1/16" in 1/16" increments and from 1 1/16" to 2" in ¼" increments. Larger or custom sizes may be available upon request. The Steel Supply Company can be contacted at (631) 385-7273 or www.thesteelsupplyco.com, and Bruce Reichelt can be contacted at (503)879-9085.

Occasionally it may be desired to obtain a waterproof or air-tight seal. As the vent/drain hole plugs are hammered in, they are already in a compressed state providing a seal. However, to ensure a long-term seal, you can apply a caulk/sealant around the hole prior to hammering in the plug and sanding the plug down. Silicone, polyurethane, or acrylic caulk/sealant types tend to adhere well to the surface. Any surface preparation recommendations for use over metals should be followed if provided by the manufacturer.