Paint

Paint is a mechanically bonded surface coating that provides a barrier film between steel and the environment. A paint system involves the use of several layers of coating, and sometimes, different formulations of paint, depending on the type of environment in which the structure will be exposed. An example of the latter may be an inorganic zinc-rich paint covered by an epoxy intermediate coat and topped with polyurethane.

The most important factor for the success of paint systems are adhesion and continuity. If paint does not adhere to the steel, it cannot protect it from the corrosive effects of the environment. Surface preparation, e.g. to SSPC SP-10, of the steel part is extremely important because the degree of paint adhesion may not be apparent immediately after application. Poor surface preparation may only manifest itself in paint failure after a few months in the field, and is evidenced by blistering, peeling, or flaking paint. Having a clean, properly prepared surface helps ensure the full potential of the paint system is realized.

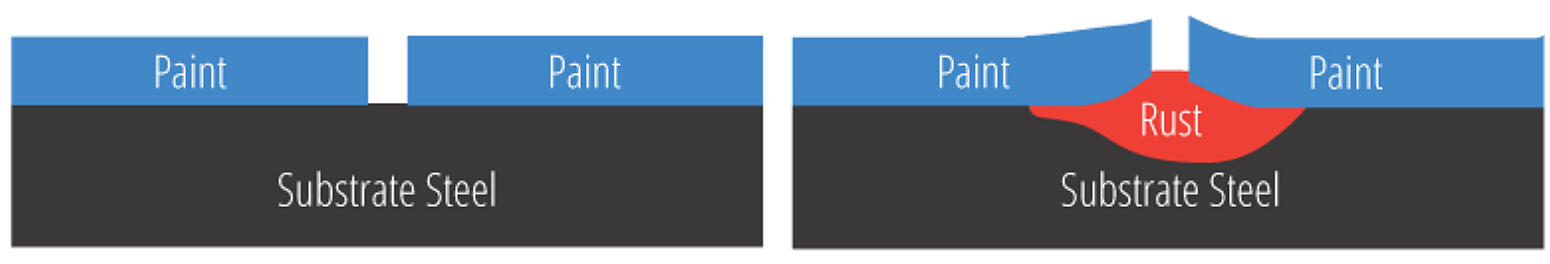

Paint can be applied to steel of any size or shape, though as mentioned, continuity of the paint systems is extremely important for carbon steel. Because of the application process (brush or spray) there will already be some inconsistencies in the coating thickness, particularly at corners and edges, and there is no coating or protection on the interior of hollow structures. The graphic below shows how corrosion begins and progresses at a pinhole, scratch, or gap in the paint coating.

In mild environments, single coat systems, such as inorganic zinc-rich paint, may be used. However, in more severe environments, a high-performance two or three coat system and regular maintenance are necessary to extend service life. There are a number of paint systems to consider and their corrosion resistance varies greatly based on different formulations and in different environments.