2022 Excellence in Hot-Dip Galvanizing Awards Showcase Innovation and Sustainability

CENTENNIAL, CO - On April 6th, the American Galvanizers Association (AGA) announced the winners of the 2022 Excellence in Hot-Dip Galvanizing Awards during the members-only Annual Conference. More than 100 projects were submitted, representing a variety of applications of hot-dip galvanizing. The finalists were judged online by a panel of architects and engineers. The submitted projects and winners are featured in the AGA Project Gallery.

This year's winners showcase sustainable and innovative uses of the hot-dip galvanized coating. This years highest honor, Most Distinguished, was given to the Malahat Skywalk in Malahat, BC. This new, immersive nature experience includes a 650m long galvanized and timber “treetop walk” which leads visitors to a 600m-long spiral walkway to the top of the structure and viewing platform. When you finish taking in the sights and sounds, you can opt to come down the “fast route” on a 20m spiral slide or return down the ramp. Hot-dip galvanizing was specified as the primary coating for the Skywalk for its natural corrosion resistance properties. With its proximity to the Salish Sea, galvanizing was the only option to achieve coating longevity while maintaining a more natural look to blend with its beautiful surroundings.

The second most prestigious award, Lifetime Achievement, is presented to projects with a minimum of 15 years in service. The 2022 Lifetime Achievement Award was awarded to two very impressive and long-standing bridges, Lane Avenue Bridge in Columbus, OH and Lizotte Bridge in Deschaillons-sur-Saint-Laurent, Quebec. Lane Avenue Bridge has stood the test of time for nearly twenty years, in part thanks to the choice to hot-dip galvanize all of the steel components on the project. The design team and owners wanted the bridge to be maintenance free to avoid future closures, as the road is a critical connection on The Ohio State University campus on either side of the river. To date, there are no signs of corrosion and no dollars have been spent maintaining the zinc coating - helping the team realize the goals set twenty years ago.

The Lizotte Bridge is the world's first fully galvanized bridge crossing the deep 200-foot span of the Chêne River with a triple arch design. The bridge used 350 tons of steel and cost $320,000 to build plus $11,000 for hot-dip galvanizing. After 58 harsh Canadian winters of salt and grit and heavy traffic, Lizotte Bridge is still earning its keep, maintenance free, and with decades of service ahead. Lizotte laid the path forward and heavy promotion by Canadian zinc companies led to the first galvanized bridge in the US in 1966. Thousands more have followed worldwide, thanks to the MTQ’s brave investment!

In addition to the Lifetime Achievement award, two more bridges were honored in this year’s awards. The Ogdensburg-Prescott Bridge in Ogdensburg, NY won this year's Bridge & Highway award. The Ogdensburg-Prescott Bridge is a mile and a half long international cable suspension bridge that connects the United States to Canada. This bridge was originally built in 1960, and recently targeted as a structure in need of rehabilitation. This rehabilitation project utilized nearly a million pounds of steel to bring the bridge up to standards.

The final bridge project awarded was the MAS Building & 2 Lowell Bridges by the Riverwalk in Lowell, Massachusetts which took home the Duplex System award. Many specifiers seek out the modern, industrial look of hot-dip galvanized steel; however, some projects call for a softer aesthetic and/or additional corrosion protection. This is often accomplished by using a Duplex System - paint or powder coating over hot-dip galvanized steel.

One interesting part of this project was convincing the architects to work with the galvanizer to design whole components built to the kettle's dimensions. Although designers are often hesitant to alter their designs, adjusting to fit the kettle can reduce cost, shorten turn around time, and improve overall aesthetics.

In addition to the Duplex winner, the Transportation award, the Bramalea GO Transit Station was also duplexed. GO Transit, a division of Metrolinx, is the regional public transit service for the Greater Toronto area, providing service to downtown Toronto. One of the station's important new features is a continuous, overhead steel canopy providing crucial shelter for inclement weather. Based on previous success, the team knew hot-dip galvanizing would provide a reliable and durable solution as well as cost savings throughout the life of the structure.

Outside of the traditional infrastructure projects, there were a couple building projects awarded. The Building and Architecture winner is 10 Fan Pier Boulevard, a 17 story, 320,000 square foot tower with residential, office and commercial space in the booming Seaport area. The mixed-use building is literally jumping distance from the sea water of Boston Harbor, where corrosion was a concern due to the wet, cold, maritime climate. This was of particular concern to the specifiers for the 110 tons of exposed roof top structures including vanity screening that would be acutely visible from surrounding buildings. With its enviable track record of reliable, long service life and unbeatable cost to benefit ratio, hot-dip galvanizing was chosen after careful study of the alternatives.

Metrolina Greenhouses and the VanWingerden family have been building greenhouses in Huntersville, North Carolina since 1972. For the last several years they have been working on a 40+ acre expansion to grow the current 162 acres of greenhouse to more than 200+ acres under roof – making it the largest single-story structure in the United States. This Metrolina Greenhouses 40 Acre Expansion won the Food & Agriculture category. Since their inception in 1972, Metrolina has chosen to hot-dip galvanize every single steel component of their greenhouse structures. After 49 years of successful coating life in the constant watering environment, the choice to hot-dip galvanize for sustainability is obvious. The VanWingerden family will continue to specify galvanizing as they continue to grow the property to supply flowers to all the large regional hardware and discount stores.

The Metrolina Greenhouses weren't the only project related to food and agriculture, two other winners included projects related to this sector. The Evrovneshtorg Grain Port Terminal Expansion in Mykoayiv, Ukraine received this year's Industrial award. The terminal serves as a strategic terminal for Ukraine’s grain trade, connecting the region’s main traffic and rail routes to the port. First opening in 2018 and with growing traffic, the EVT terminal hit its capacity and required an expansion to keep up with demands. Not only does this terminal allow more local farmers to sell and ship grain around the world, but it is also one of the largest employers in the community. By installing quality equipment, protected by hot-dip galvanizing, they will be able to provide high paying jobs in this region for generations.

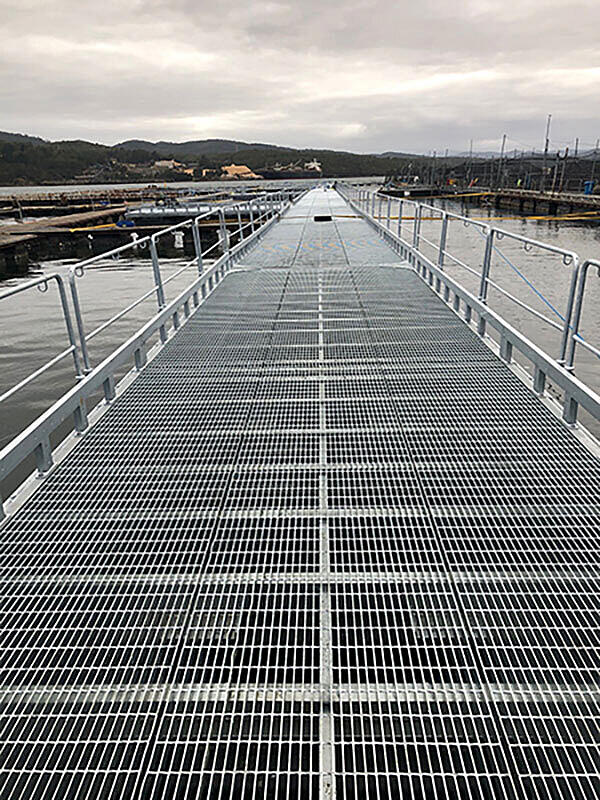

The Petuna Group Rowella Salmon Farm Reconfiguration won the International category. This projects is dedicated to ethical and sustainable practices when it comes to salmon farming. Rowella employs a state-of-the-art hatchery recirculation system using less than 5% of the water consumed in traditional hatcheries. The company also stocks its marine farms at some of the lowest commercial stocking densities in the world, exemplifying its dedication to environmental responsibility. Sustainability and fish health are imperative to Petuna Group’s business model. As a growing market, additional salmon farms will require refurbishment and/or expansion. Hot-dip galvanizing, which is safe for both the fish and flowing river water, extends the life of their pens, reducing the number of raw materials needed to replace obsolete structures.

Like the Industrial Award, the Artistic Award was galvanized in the U.S., but installed overseas. The Footballers, is a masterful galvanized art piece located right outside the Manchester City Football club stadium in Manchester, England. In September 2021, MCFC unveiled two incredible statues designed as everlasting tributes to recently retired Vincent Kompany and David Silva. When the club came across works created by world-renowned sculptor Andy Scott, they knew it was the style they were looking for. His unique sculpting technique utilizing hot-dip galvanized steel was ideally suited to the city’s industrial heritage and the proud “blue-collar” roots of the club.

American football was also present in the 2022 Excellence Awards with Protective Stadium: UAB Blazers winning the Recreation and Entertainment category. The new 45,000-seat stadium is Birmingham, AL new entertainment district centerpiece. The $200 million civic infrastructure investment must live up to the hype and preserve its beauty and stature for decades to come which is why the reliable corrosion protection system - hot-dip galvanizing was specified. The hot-dip galvanized, aesthetically pleasing venue will be highly visible to all downtown visitors, students and tourists, promoting HDG as the preferred coating for outdoor venues.

From a stadium for college football, to a project designed and built by college students, the Topeka Children's Discovery Center, nestled in the plains of Topeka, Kansas won the Civic Contribution award. It's core missions is to enhance the lives of children and enrich the communities. When the University of Kansas' School of Architecture and Design was approached to help build a canopy for the center, the students jumped at the chance to get hands on experience while giving the current and future generations of children a place to enjoy. KU students approached the galvanizer with this project in hopes to accomplish their goal of providing a long-lasting solution to the children that visit the Discovery Center daily.

Another innovative canopy system was one of the projects awarded for Original Equipment Manufacturing. Schomp Automotive Group developed a system to mitigate the damage from hailstorm threat. In 2021, Schomp began to construct a hail-net system called “Hail No” to protect their exposed car inventory. This creative design uses large 10” and 12” diameter HDG steel tube columns set in concrete to support a strong netting system with spans as long as 63’, capable of supporting up to a foot of snow. The netting system is designed to be easily taken down and stored for the winter months when snowstorms can occasionally exceed the Hail No system load capacity.

The other winner in the Original Equipment Manufacturing category was Iscar GSE who designs and builds state-of-the-art ground services equipment for the aviation community. Slave racks are put to work in transporting facilities, which are in heavy industrial and/or tropical marine environments. The setting is also very rugged due to the constant flow of materials. By hot-dip galvanizing, Iscar GSE not only protects the steel equipment from rusting but also from damages caused by the heavy demand of transporting the pallets from one location to the other.

Another OEM product, the 2512 Underwater Pipe Carrier from Omaha, NE, was honored with the Water & Marine Award. It was designed to assist in the replacement of damaged underground pipes that deliver safe, reliable drinking water. Rather than replacing the cracking and degraded portions of the tunnels, the Underground Water Pipe Carrier facilitates relining the existing structure. The carrier is sent down the tunnels as a kit of parts and then put together underground. This new process extends the life of the water utility without interruptions to service for a much lower price.

The final 2022 Excellence Awards winner is in the Electric, Utility, and Communications category - one of HDG's longest and most common uses. In 2021, Manitoba Hydro completed the new 695-megawatt Keeyask Power Generating Station, the largest project in the Northern Manitoba, Canada in decades. The Station features 16 miles of dam structures, a switching station, and hundreds of miles of transmission and distribution lines. Hot-dip galvanizing was used for all exposed steel. This included everything from transmission towers, railings, anchor rods, scaffolding, cables, guardrail, fencing and pole line hardware of supporting access roads. All benefitted from the unbeatable economic advantage and durability of hot-dip galvanizing.

Hot-dip galvanizing is a mainstay in many traditional sectors, but more and more specifiers are incorporating galvanizing into new and innovative projects to capitalize on its durability and sustainability. To see more hot-dip galvanized steel projects including other submissions to the 2022 competition and past winners, please visit the AGA Project Gallery.

Contact AGA Marketing Coordinator Rebecca Spodick for more information, high quality images, or specific project articles.

Complete List of Winners, by Category:

| Category | Project | Location | Galvanizer(s) |

| Most Distinguished | Malahat Skywalk | Malahat, British Columbia | Silver City Galvanizing, Inc. |

| Lifetime Achievement | Lane Avenue Bridge | Columbus, OH | V&S Columbus Galvanizing |

| Lifetime Achievement | Lizotte Bridge | Deschaillons-sur-Saint-Laurent, Quebec | Corbec Group - Montreal |

| Artistic | The Footballers | Manchester, United Kingdom | Valmont Coatings - American Galvanizing |

| Bridge & Highway | Ogdensburg-Prescott Bridge Rehab | Ogdensburg, New York | V&S New York Galvanizing |

| Building & Architecture | 10 Fan Pier Boulevard Boston Harbor | Boston, Massachusetts | Corbec Group - Princeville |

| Civic Contribution | Topeka Children's Discovery Center | Topeka, Kansas | AZZ Galvanizing - Kansas City |

| Duplex Systems | MAS Building & 2 Lowell Bridges by the Riverwalk | Lowell, Massachusetts | Duncan Galvanizing Corp. |

| Electrical, Utility, & Communication | Keeyask, Manitoba | Corbec Group - Quebec | |

| Food & Agriculture | Metrolina Greenhouses 40 Acre Expansion | Huntersville, North Carolina | Galvan Industries, Inc. |

| Industrial | Mykolayiv, Ukraine | Valmont Coatings - West Point Galvanizing | |

| International | Rowella, Australia | Valmont Coatings | |

| Original Equipment Manufacturing | Highlands Ranch, Colorado | AZZ Galvanizing - Denver | |

| Original Equipment Manufacturing | Iscar GSE Airport | Miami, FL | Valmont Coatings - Miami Galvanizing |

| Recreation & Entertainment | Birmingham, AL | AZZ Galvanizing - Crowley | |

| Transportation | Bramalea GO Transit Station | Brampton, Ontario | Valmont Coatings - Pure Metal Galvanizing Mississauga |

| Water & Marine | 2512 Underwater Pipe Carrier | Omaha, NE | Valmont Coatings - Valley Galvanizing |