AGA Resources on HDG Coating Appearance

Many specifiers think newly hot-dip galvanized parts will be shiny and spangled; similar to continuous sheet galvanized steel products. In reality, batch or after-fabrication hot-dip galvanized steel can take on a number of initial appearances including bright and shiny, spangled, matte gray, or a combination of these. The initial appearance is often difficult to predict for a variety of reasons, but is most influenced by steel surface chemistry, cooling rates, and stresses induced during steel processing. Regardless of the initial appearance, all galvanized steel parts will take on a uniform matte gray appearance upon exposure to the environment, typically within six months to two years.

Many conditions found on the galvanized surface are acceptable despite the impact on aesthetics in the short-term, while others are deemed not acceptable because they affect the corrosion resistance and/or intended use of the product. To assist you in interpreting the specification requirements, the AGA has developed a variety of resources for identifying and explaining the reason for common coating appearances and will continue to develop new resources throughout 2020.

The AGA publication, Hot-Dip Galvanized Coating Appearance provides an overview of coating appearances common for newly galvanized steel. This publication includes pictorial examples, reasons or mitigations for each appearance, and whether the appearance will become uniform over time.

Meanwhile, our online training course entitled Inspection of Hot-Dip Galvanized Steel provides detailed instruction for inspectors, architects, engineers and other specifiers regarding the inspection of galvanized steel and explanations for surface conditions which are acceptable or rejectable according to relevant ASTM standards. The same information is also available through an instruction guide and through a comprehensive mobile application.

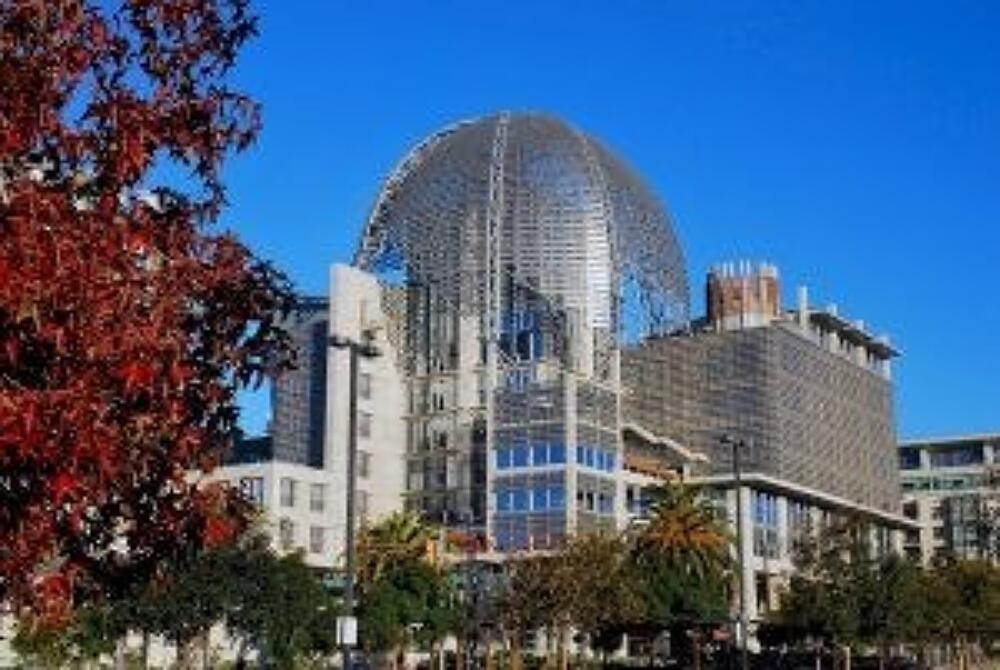

In 2020, be on the lookout for a new video series which will more closely demonstrate the impact fabrication practices, steel selection, and the galvanizer have on the appearance and quality of hot-dip galvanized coatings. Topics to be explored in the Hot-dip Galvanized Coating Appearance video series include: Steel Chemistry and Cooling Rates, Welding, HDG Process Influences, and Post-Galvanizing Considerations. In addition to the video series on appearance, the AGA is developing visual samples and an instructional guide to assist specifiers wishing to hot-dip galvanize Architecturally Exposed Structural Steel (AESS). Currently, there is a common misconception it is not possible to obtain AESS quality galvanized steel because many surface conditions normally acceptable in the primary galvanizing standards (i.e. runs, skimmings, roughness, excess zinc) may not be acceptable for showcase or feature elements without additional and costly detailing by the galvanizer and/or fabricator. To address these concerns, the AGA is working to develop a supplemental guide to AISC/CISC’s existing guides using the AESS Custom category. This guide will also include best practices to facilitate communication, minimize cost premiums, maximize aesthetic appearance through a combination of design, fabrication, and galvanizing techniques. This guide is also scheduled for publication in 2020.