2021 Excellence in Hot-Dip Galvanizing Awards Showcase Ingenuity and Innovation

CENTENNIAL, CO - The votes have been tallied and the American Galvanizers Association (AGA) is pleased to announce the winners of the 2021 Excellence in Hot-Dip Galvanizing Awards. More than 105 projects were submitted, representing a variety of applications of hot-dip galvanizing. The finalists were judged online by a panel of architects and engineers. The submitted projects and winners are featured in the AGA Project Gallery.

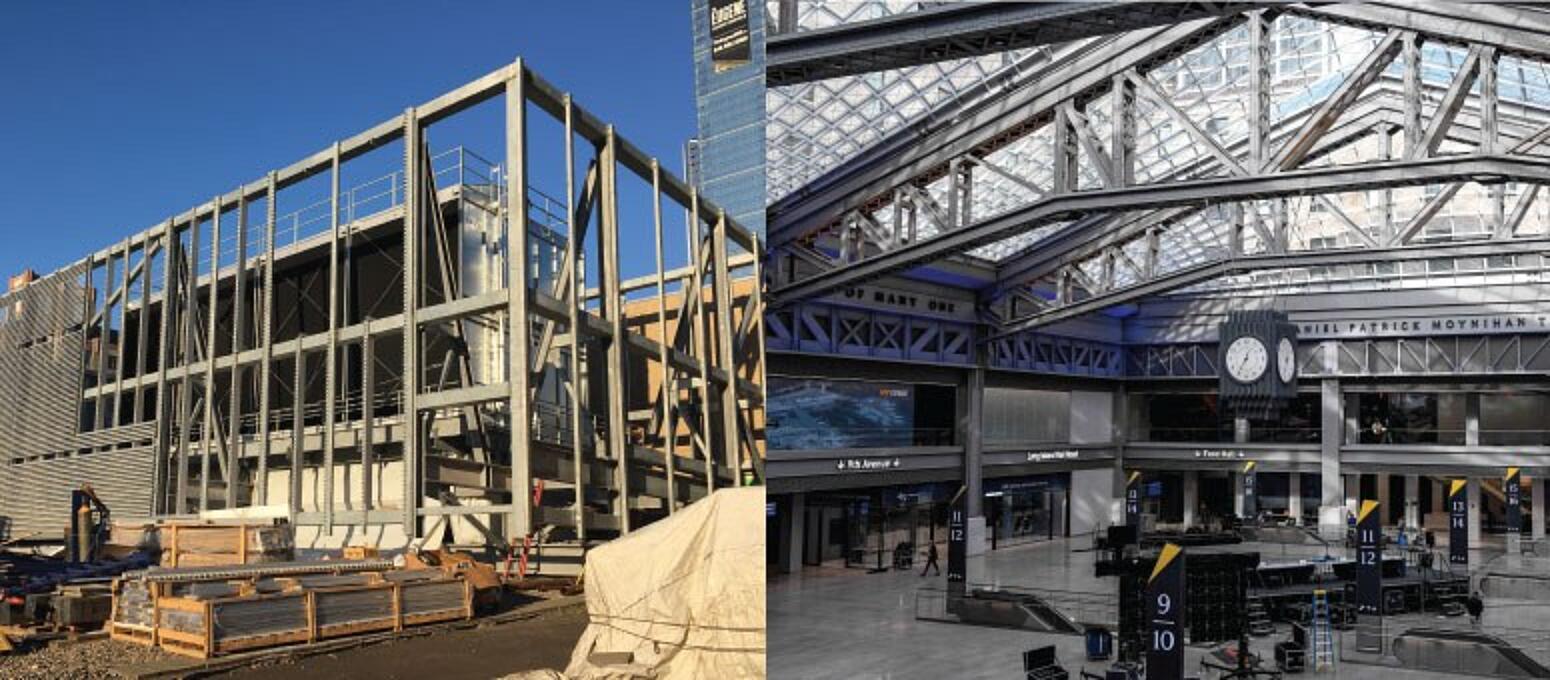

This year’s winners showcase creative and innovative uses of the hot-dip galvanized coating. This year’s highest honor, Most Distinguished, was given to the Moynihan Station in New York City. The Farley Building’s redevelopment into the Moynihan Train Hall has created a new 255,000-square-foot Train Hall for Long Island Rail Road and Amtrak passengers and increased total concourse floor space in the Pennsylvania Station-Farley Complex by more than 50 percent. With tons of steel components exposed to the commuters visually hot-dip galvanizing was an obvious choice to assure a long life-cycle, minimal maintenance and provide aesthetic value.

The second most prestigious award, Lifetime Achievement, is presented to projects with a minimum of 15 years in service. The 2021 Lifetime Achievement Award was granted to the Val-des-Bois Bridge in Bowman, Quebec. This traditional truss style bridge spans approximately 225 feet, has two traffic lanes and entered service in 1964. Crossing the Du Lievre (Jackrabbit) River about one hour north of the Canadian capital of Ottawa, this bridge faced brutal conditions since its erection. This led to the decision in 1960 to install a series of hot-dip galvanized bridges. Amazingly, every bridge is still in service 50 to 60 years later with a first maintenance almost 50 years into the service life.

In addition to the Lifetime Achievement award, another Canadian bridge completed in 2020 was honored in this year’s awards. The Passerelles Beauport pedestrian bridges, located in Quebec, received the Bridge & Highway award. These galvanized steel walkways were easily and quickly installed with minimum impact on the local environment. Even more importantly, the maintenance free, long lasting and natural qualities of hot-dip applied pure zinc will please all stakeholders; from the municipality owners to the citizen users and even the waters, plants and animals beneath.

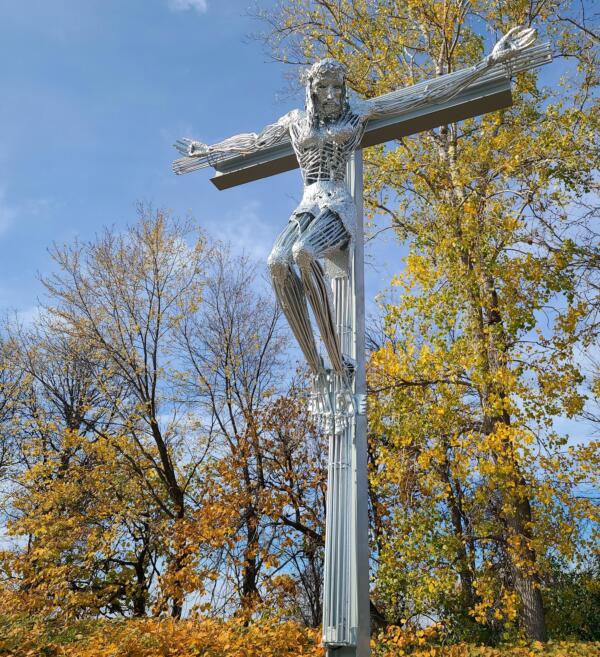

Another Quebec-based project, Calvaire, a Crucifix statue, won the Civic Contribution award. The decision to galvanize was both artistic and practical. The long-lasting durability and low cost of hot-dip galvanizing was an ideal fit and the tightly spaced bars precluded any possibility of fully painting every surface of the statue. Artistically the neutral and natural monotone of the zinc coating works beautifully, no colors or details to distract from the stark image of the real humanity of the tragic event it depicts.

Another unique statue that won this year’s Artistic award was the Ullr Breck – Norse God of Snow. The 25-foot tall, one-ton design made of 1-inch pieces of welded steel took just over a year to complete. Galvanizing not only protects Ullr from corrosion, but also provides great aesthetic appeal. Ullr now stands tall, watching over the Colorado mountain. Breckenridge visitors will be able to pay homage to the Norse God of Snow and send him prayers for good ski conditions. He will be the centerpiece of Ullr Fest and the galvanized masterpiece is bound to be heavily photographed by visitors, employees, and media for decades to come.

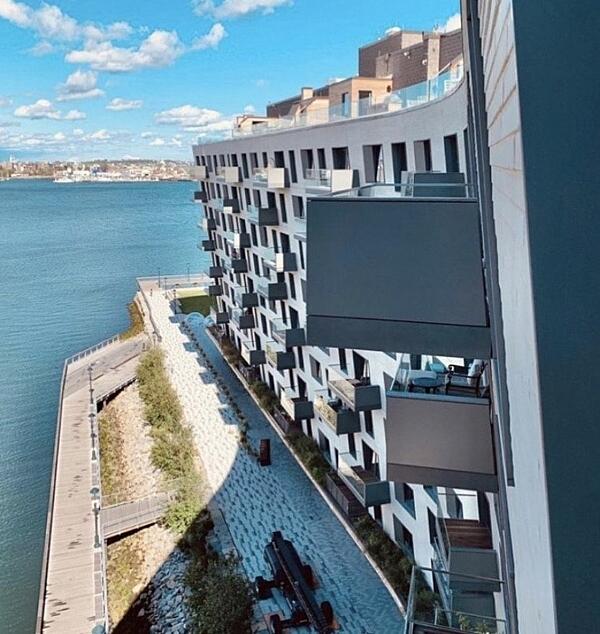

The Building & Architecture category had a variety of hot-dip galvanized projects from all over North America, but the Balconies at Pier 4 Residences in Boston stood above the rest. The 106-unit luxury building is surrounded by water on three sides in Boston’s most dynamic new neighborhood. Taking advantage of the outstanding views, all residences will feature balconies with unrestricted water views from all sides. The architectural team wanted to make certain the finish on the railings would withstand the effects of continuous exposure to salt spray from the ocean. They made their decision to specify a duplex system of galvanizing and paint based on their previous experience.

Many specifiers seek out the modern, industrial look of hot-dip galvanized steel; however, some projects call for a softer aesthetic and/or additional corrosion protection. This is often accomplished by using a Duplex System - paint or powder coating over hot-dip galvanized steel. This year, the Lauderhill Mall Transit Center was honored with the Duplex System award. The design team determined a duplex coating would satisfy all their requirements. The synergistic effect of the two systems would provide the 1.5 to 2.3 times the life span of either system used on its own, while the blue topcoat pops against the mosaic architectural façade on the buildings. This supreme coating system will protect the canopy from its environment while it protects passengers from the elements.

In addition to the Most Distinguished Moynihan Station and the Duplex System winner, another transit station, the Northside Transit Center in Cincinnati, Ohio, was honored with this year’s Transportation award. Northside is Metro’s second-busiest transfer location, after Government Square downtown. The galvanizer was able to assist and educate both the design team and the fabricator of optimal design and fabrication for galvanizing. This included proper venting and draining, steel chemistry selection and weld wire selection. Ultimately the appearance concerns were eased and galvanizing was selected over paint due to lifecycle cost, coating durability and corrosion protection

This year, two projects were honored in the Electrical, Utility & Communication market and both used a bit of ingenuity and innovation. Turquoise Solar sits on approximately 180 acres of igneous rock and a ledge at a mountainous base and delivers power to one of Apple’s largest data centers. Nothing other than hot-dip galvanizing stands up to the task of being drilled into rock while protecting the steel for decades to come. The demanding project in terms of schedule, galvanizing turnaround, difficulty of installation and challenging terrain make this utility scale solar project one-of-a-kind.

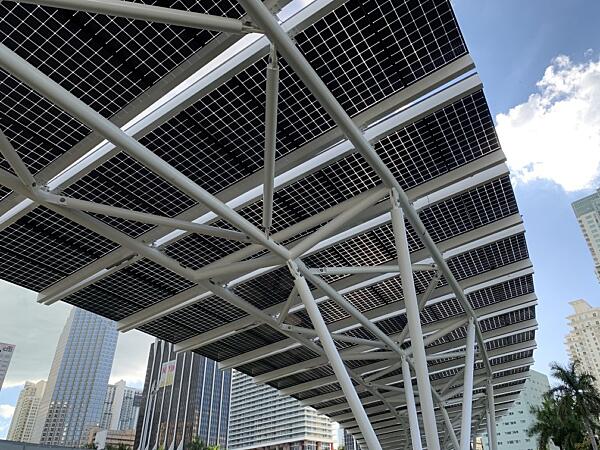

The Florida Power and Light (FPL) Solar Amphitheater at Bayfront in Miami utilizes cutting edge, bifacial solar technology, which is able to capture light and produce energy from both sides of the photovoltaic panel. Hot-dip galvanizing was selected to provide maintenance free protection for all structure surfaces, both internal and external. An internal hot-dip galvanized coating will prevent the possibility of any undetectable, internal corrosion. This solar installation coupled with a complement of seven solar trees, generates in excess of 250 kilowatts of emissions-free energy annually. That’s more electricity than will be consumed during the amphitheater’s entire concert season.

Another critical use of hot-dip galvanized steel is in the manufacturing industry, as demonstrated by the winner of the Industrial award. A new Enzyme Spray Unit Facility in Franklinton, North Carolina, received the 2021 award. This new facility will produce enzymes that will be sold to a variety of markets. Enzymes help companies cut costs, optimize production, and create better products. The use of these more sustainable solutions are widely used in our everyday lives in industries such as farming, medical and food production. The new facility consists of 348 tons of steel - 193 tons of which were hot-dip galvanized.

Expansion has been ongoing as part of a five-year capital investment project to improve beet receiving, washing and chip recovery at Michigan Sugar Company's Croswell factory. The recent expansion was honored with this year’s Food and Agriculture award. The team wanted to increase overall production while building a system without interruptions in production. As a result, they decided to hot-dip galvanize the entire washer system and the entire building. This combination will help to protect both structures from the beet washing process and the acidic chemical involved.

All Original Equipment Manufacturers are looking for a way to stand out and provide unique value to their products. This year’s winner in the OEM category was the Colorado Division of Fire Prevention and Control water tanks. In 2020, the state of Colorado had 3 record breaking fires, and a critical component in the DFPC firefighting arsenal is the foam spraying on/off-road firefighting vehicles. These powerful trucks are equipped with a low-profile 850-gallon hot-dip galvanized steel water tank. The all-encompassing success of these HDG tanks provides a powerful testimonial for any other organizations that may be experiencing a costly, corrosion related problem.

At $5.5 billion, the most expensive stadium complex in the world cannot afford maintenance issues due to corrosion of the beautiful white canopy that encircles the building. The best corrosion protection system was needed to build the SoFi Stadium in Los Angeles, which received the 2021 Recreation and Entertainment award. Over 70,000 tons of steel was used on this project. The powder coated hot-dip galvanized steel system wraps around the stadium and provides a beautiful centerpiece to a newly re-imagined neighborhood in the world class city of Los Angeles

The Hudson River Park Pier 26, located in New York City, was honored with the Water & Marine award. This 2.5-acre ecologically-themed pier in Tribeca leads visitors through five native ecological zones: woodland forest, coastal grassland, maritime scrub, rocky tidal zone, and of course the Hudson River. The fabricator partnered with the galvanizer in order to assure the Hudson River Park Trust that the proper selection of materials would be critical to the success and longevity of the project. Several case studies were presented of similar projects in the same environments. The galvanized coating on all the access rails, supporting structures and access walkways will be able to protect this structure in its natural environment for decades to come.

The International category honors projects completed by associate members – galvanizers outside of North America. This year’s winner was the Exotic Aviary Geodesic Dome located in India. Inside the Sardar Patel Zoological Park near the Statue of Unity in Kevadia Narmada district, it is the world’s largest geodesic dome. The steel structure required a coating that would be inherently sturdy, protecting against any abrasion with a lifespan of at least 20 years without maintenance. All 100 metric tons of steel used for this project were hot-dip galvanized to withstand the environmental conditions.

Hot-dip galvanizing is a mainstay in many traditional, but more and more specifiers are incorporating galvanizing into new and innovative projects to capitalize on its durability and sustainability. To see more hot-dip galvanized steel projects including other submissions to the 2021 competition and past winners, please visit the AGA Project Gallery.

Contact AGA Marketing Coordinator Alison Walsh for more information, high quality images, or specific project articles.

Complete List of Winners, by Category:

| Category | Project | Location | Galvanizer(s) |

| Most Distinguished | Moynihan Station | New York, NY | Southern Galvanizing Company |

| Lifetime Achievement | Val-des-Bois Bridge | Bowman, Quebec | Corbec Inc. |

| Artistic | Ullr Breck - Norse God of Snow | Breckenridge, CO | Valmont Coatings - American Galvanizing |

| Bridge & Highway | Passerelles Beauport | Beauport, Quebec | Corbec Inc. |

| Building & Architecture | Balconies at Pier 4 Residences | Boston, MA | Duncan Galvanizing Corp. |

| Civic Contribution | Calvaire, a Crucifix Statue | Gatineau, Quebec | Corbec Inc. |

| Duplex Systems | Lauderhill Mall Transit Center | Lauderhill, FL | Valmont Coatings - Miami Galvanizing |

| Electrical, Utility, & Communication | Turquoise Solar | Sparks, NV | V&S Columbus Galvanizing |

| Electrical, Utility, & Communication | FPL Solar Amphitheater at Bayfront | Miami, FL | AZZ Galvanizing - Denver |

| Food & Agriculture | Michigan Sugar Croswell Expansion | Croswell, MI | V&S Detroit Galvanizing |

| Industrial | Enzyme Spray Unit Facility | Franklinton, NC | Valmont Coatings - Virginia Galvanizing |

| International | Exotic Aviary Geodesic Dome | Kevadia, India | Valmont Coatings |

| Original Equipment Manufacturing | Colorado Division of Fire Prevention and Control | Lakewood, CO | AZZ Galvanizing - Denver |

| Recreation & Entertainment | SoFi Stadium | Los Angeles, CA | AZZ Galvanizing - Joliet |

| Transportation | Northside Transit Center | Cincinnati, OH | V&S Columbus Galvanizing |

| Water & Marine | Hudson River Park Pier 26 | New York, NY | V&S Columbus Galvanizing |