Beneath the Surface: Evaluating Hot-Dip Galvanized Steel Underground

Whether in the atmosphere, submerged in water, or embedded in soil, there are many different corrosion mechanisms that impact the longevity of hot-dip galvanized steel. Most commonly hot-dip galvanizing is used to protect structures exposed to the atmosphere. The corrosion mechanisms in this environment as well as the life expectancy of hot-dip galvanized steel have been studied thoroughly and proven through structures that have been in place for decades. However, when it comes to soil and water applications, the corrosion factors and life expectancy can become much murkier.

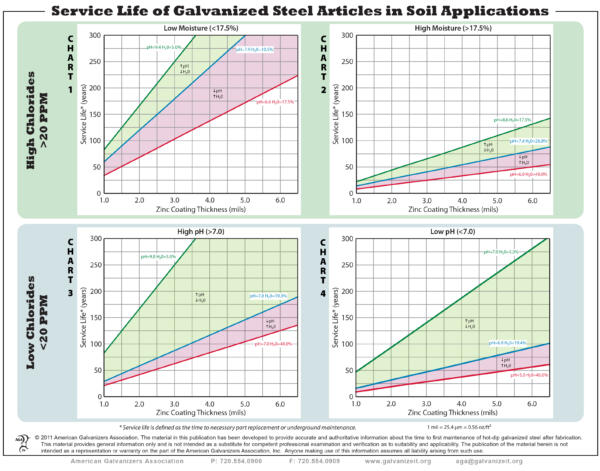

In 2011, the American Galvanizers Association (AGA) developed the Service Life of Galvanized Steel Articles in Soil Applications. The series of four charts provides an estimate of how long hot-dip galvanized steel will last based on three primary soil characteristics: chloride level, moisture content, and pH. The service life is defined as total consumption of the zinc coating plus 25%, which would be when replacement is likely necessary. The charts are a great tool to estimate the service life at the outset of the project. However, unlike atmospheric applications where it is easy to visually inspect the galvanized coating, it is much more difficult to know if the galvanized steel is performing as expected below grade (underground).

There are a number of products that use hot-dip galvanizing below grade, but one of the most common is transmission and distribution utility poles. As everyone is likely aware, North America’s infrastructure is aging and in need of improvements. According to the most recent Report Card for America’s Infrastructure, produced by the American Society of Civil Engineers (ASCE), the Energy Infrastructure is graded as a D+. A good portion of that grade has to do with the aging electrical grid, some of which was built in the 1880s, but the vast majority was installed following World War II. Therefore, much of the infrastructure has met or surpassed its original design life, and is likely in need of replacement.

The “baby boomer” generation of transmission and distribution poles compromise a large percentage of the electrical grid; therefore, it is critical to stay ahead of the deterioration of these structures. This fact led the Institute of Electrical and Electronics Engineers (IEEE) and the National Association of Corrosion Engineers (NACE) to develop a joint committee to assess these structures and develop standards for the inspection and repair/replacement of the aging poles. As stated before, the atmospheric evaluation and inspection is relatively simple and well understood. However, the joint group has also developed standards to assess and inspect the structures below grade, which has implications beyond the utility market.

NACE/IEEE have issued three joint standards of practice for the evaluation of aging power structures:

- NACE SP0315-2015/IEEE Std 1835-2014: NACE International and IEEE Joint Standard Practice for Atmospheric (Above Grade) Corrosion Control of Existing Electrical Transmission, Distribution, and Substation Structures by Coating Systems

- NACE International SP0215-2015/IEEE Std 1839-2014: NACE International and IEEE Joint Standard Practice for Below-Grade Corrosion Control of Transmission, Distribution, and Substation Structure by Coating Repair Systems

- NACE SP0415-2015/IEEE Std 1895-2014: NACE International and IEEE Joint Standard Practice for Below-Grade Inspection and Assessment of Corrosion on Steel Transmission, Distribution, and Substation Structures

All of these specifications are available on the NACE website. (There is no cost for NACE members, non-members can purchase them).

As aging infrastructure is being replaced, it is a great time to re-evaluate the materials and corrosion protection systems utilized. The long-term, real world applications will give a more complete picture of how each material and/or protection system performed in its environment. This data is much more valuable than accelerated testing or service life projections. With sustainability in mind particularly in the distribution pole market, it will also be important to evaluate the recent decision of the Stockholm Convention to list pentachlorophenol-treated wood poles on Annex A, which means the use of pentachlorophenol would be prohibted for signatory countries in five years.

Building sustainable infrastructure should be a primary goal for North America. The standard of practice released by NACE/IEEE to evaluate the corrosion of steel below grade is another tool to look beneath the surface and understand how various steel coating systems perform underground. The ability to know what materials are sustainable and which structures are in need of replacement are huge steps in ensuring our infrastructure is safe and sustainable for future generations.