AGA Releases Environmental Product Declaration (EPD) for Galvanized Steel

The American Gavlanizers Association (AGA) is pleased to announce the release of an industry-wide Environmental Product Declaration (EPD) for hot-dip galvanized steel after fabrication. The EPD was conducted by thinkstep, Inc. and verified by UL Environment, Inc. to meet the new requirements of LEED v4 Building Product Disclosure and Optimization (BPDO) credit for Environmental Product Declarations (EPDs).

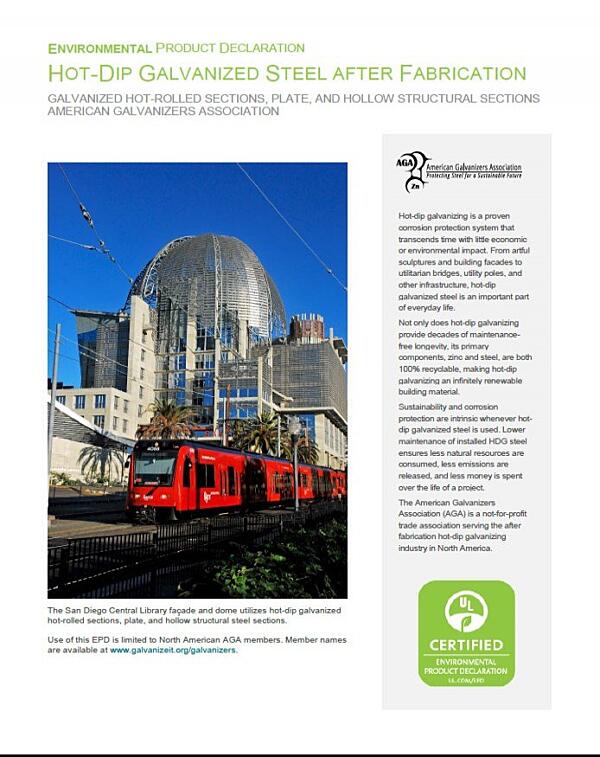

The EPD covers galvanized hot-rolled sections, plate, and hollow structural sections and includes background steel and fabrication data from the American Institute of Steel Construction (AISC) and the Steel Tube Institute (STI) as well as zinc background data from the International Zinc Association (IZA) and hot-dip galvanizing information collected from AGA members in North America.

The EPD includes hot-dip galvanizing industry averages for energy demand, global warming potential, acidification potential, eutrophication potential, and photochemical ozone creation potential from cradle (raw material acuqisition) to gate (end of the galvanizing process). The EPD also identifies credits for recycling done within the galvanizing process. According to Option 1 of the LEED v4 BPDO credit for EPDs, this industry-wide EPD provides one-half credit toward the requirement of 20 EPDs from at least five different manufacturers.

In addition to the comprehensive EPD, the AGA has released three verified transparency briefs - one for each product in the EPD: galvanized hot-rolled structural sections, HDG steel plate, and galvanized hollow structural sections (HSS). The transparency briefs are a quick snapshot of the environmental impacts of producing each of the galvanized products.

Please note, the AGA's EPD can only be submitted for project credit by active North American member galvanizers who supported this study. For a list of active members, please search our Galvanizer Locator.