2020 Excellence in Hot-Dip Galvanizing Awards Showcase a Vision for a Sustainable Future

CENTENNIAL, CO - The votes have been tallied and the American Galvanizers Association (AGA) is pleased to announce the winners of the 2020 Excellence in Hot-Dip Galvanizing Awards. More than 115 impressive projects were submitted, representing a variety of applications of hot-dip galvanizing. All of the projects were judged online by a panel of architects and engineers. The submitted projects and winners are featured in the AGA Project Gallery.

This year’s highest honor, Most Distinguished, was given to the Humber College Parking Structure in Toronto, Ontario. The seven-story structure provides 28,000 square meters of parking area with 1,000 car spaces and 700 square meters of bike storage, retail, office, and ancillary space. The garage was built to replace and improve upon the surface lot that was lost with the building of the new Centre for Technology and Innovation. All steel components of the main and secondary structure as well as miscellaneous metals were hot-dip galvanized to secure the long-term durability of the building and low maintenance requirement.

The second most prestigious award, Lifetime Achievement, is presented to projects with a minimum of 15 years in service. The 2020 Lifetime Achievement Award was granted to the Riviere Cochon Gras Bridge in Perches, Haiti. In its previous life, this bridge made up part of the massive temporary bridge on Route 3A connecting Quincy, MA with Weymouth, MA. Hot-dip galvanizing was the only coating able to stand the test of time serving 15 years as the Fore River Bridge in Massachusetts only to be disassembled, shipped halfway around the world, and then reused in Haiti with no signs of corrosion or repair required. In Perches, there was an unpaved road with no crossing, which was the only way to access a local hospital and an industrial park to the North. During the three or four rainy months, the crossing is frequently impassable. The reused bridge section will literally be a lifesaver for the residents in the community.

In addition to the Lifetime Achievement award, two other bridges completed in 2019 were honored in this year’s awards. A Tale of Two Bridges, located in Montreal, Quebec, received the Bridge & Highway award. By its 30th birthday, the Champlain Bridge was already facing major corrosion problems. The entire concrete road deck and jersey barriers of the cantilever section required emergency replacement due to severe uncoated rebar corrosion. Due to the imminent risk of collapse, the New Champlain Bridge was built at breakneck speed, but also considered the lessons learned. All structural steel that could physically fit in the local kettles was hot-dip galvanized, along with all railings, anchors, signage and wind braces. This project highlights the monumental dangers and costs of infrastructure corrosion and multifaceted benefits of long-lasting hot-dip galvanized steel.

The Civic Contribution award bestowed upon The Living Bridge, located in Portsmouth, NH, is an interdisciplinary smart infrastructure research project, converting the Memorial Bridge into a demonstration "smart bridge." The Memorial Bridge is over the Piscataqua River, which links Portsmouth, New Hampshire to Kittery, Maine. The river is considered a harsh marine environment and the team was concerned the corrosive environment would ultimately destroy the steel platform. When the local galvanizer heard of their concerns, they met with the Project Manager to explain how hot-dip galvanizing would protect the steel and offered to donate the galvanizing services to ensure the research project would survive the conditions.

The Building & Architecture category had a variety of hot-dip galvanized projects from all over North America, but the MacKimmie Tower stood above the rest. The University of Calgary recognized the need to re-energize the central hub of the campus while creating additional space for classrooms, administrative support units and faculty departments. Thus, the redevelopment of the MacKimmie Complex was born. While supporting the need for additional space, the goal of this multi-year project is to act as a pilot for a Canadian Net Zero Carbon Building standard and help develop a tool that can successfully support post-secondary institutions going forward. The MacKimmie Tower provided the opportunity for students and faculty members to be engaged throughout the design and construction phase. This process encourages future generations to think outside the box, reflecting new knowledge for general well-being for many years to come.

Another Calgary-based project, The Calgary MAX Transit Shelters, won the Transportation Award. The two key components of sustainability and affordability are addressed by using hot-dip galvanized steel on the shelters. Steel is a sustainable material because it can be infinitely recycled, so the investment in making steel is never wasted and can be employed by future generations. Using hot-dip galvanizing as the protection system for steel provides a maintenance free coating that extends the life of the structure with minimal environmental impact. Both zinc and steel are natural, abundant and 100% recyclable, providing the City of Calgary with the sustainable and affordable solution they sought.

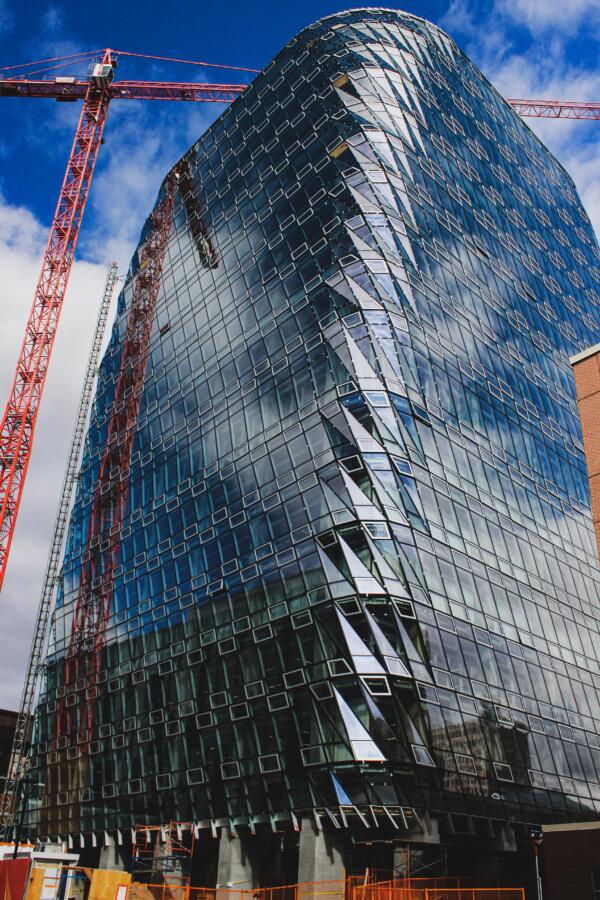

Many specifiers seek out the modern, industrial look of hot-dip galvanized steel; however, some projects call for a softer aesthetic and/or additional corrosion protection. This is often accomplished by using a Duplex System - paint or powder coating over hot-dip galvanized steel. This year, two projects were honored with the Duplex System award: the Oregon Convention Center Parking Façade and Louis Armstrong New Orleans International Airport. The Oregon Convention Center (OCC) Parking Facade, located in Portland, has a unique sail effect created by these assemblies, making this parking structure an aesthetically pleasing building in the heart of Portland's central east side convention center complex and compliments the newly built Hyatt Regency next door. When looking westward towards downtown, the duplex coated sails are a great addition to the Portland skyline.

The Louis Armstrong New Orleans International Airport in Kenner, LA, serves more than five million passengers a year through its 35 gates using HDG stairs and handrails to access lower levels. Visitors and passengers arriving at the airport will be welcomed by the aesthetically pleasing white canopies, supported by duplex coated tubular frames. The designers chose hot-dip galvanizing because of its sustainability and ability to meet the requirement of a 50-year life with a low maintenance cost.

The two projects honored with the Duplex Systems award were not the only winning projects that incorporated a duplex system. The world’s first cable-to-rail zip line roller coaster, The Flying Ox, took home the Recreation & Entertainment award. Located in Pigeon Forge, Tennessee, the Flying Ox dominates the landscape of Lumberjack Square at 1,000 feet in length and 80 feet in height. The corrosion protection and aesthetics achieved by combining hot-dipped galvanizing with a paint-duplexed layer have enhanced this project in a way that will no doubt ensure families are able to enjoy the Flying Ox for years to come.

Another project for recreational use is the High Seas Log Flume, receiving the Water & Marine award. Located in Ocean City, NJ, the log flume is open to the salt air and harsh weather all year round, and besides these harsh conditions, the ride uses chlorine water that accelerated corrosion of carbon steel. The owners knew they wanted to utilize hot-dip galvanizing on the refurbishment of this timeless amusement ride. The parts were completely disassembled and tracked, and then channel pans and structural beams and columns were stripped of their original galvanizing, repaired, inspected and then galvanized again. Thanks to hot-dip galvanizing, this ride will stand the test of time for another forty years.

Hot-dip galvanized steel’s versatility and unique aesthetic often makes it a top choice for artistic projects. The Artistic category winner, Bloom, is a masterful galvanized art piece located in downtown Reno, Nevada. The dimming and glowing of the bloom brings the piece to life. Its beauty is difficult to portray but can best be described as witnessing beauty and the creation of life. Hot-dip galvanizing was used for extended corrosion protection and to provide a uniform look for the art piece.

Another unique sculpture that won this years International award was the Triberg Eagle. Located in Triberg, Germany, this impressive giant Eagle sculpture marks the entrance to the New Greifvogel- und Eulenpark, a new bird of prey zoo in Triberg, in the heart of the Black Forest. With intricate workmanship it was important the piece was protected, leading to the decision to hot-dip galvanize the complete sculpture and stand. The galvanized coating not only provided the aesthetic finish desired, but also ensures the sculpture will be protected from the environmental elements, avoiding damage and corrosion.

Another critical use of hot-dip galvanized steel is in the manufacturing industry as demonstrated by the winner of the Industrial award. The new sand processing plant, North American Aggregates, received the 2020 award. Located in Perth Amboy, NJ, The mining and crushing equipment at the plant are all hot-dip galvanized to protect against corrosion in this marine environment. Mellott Company worked directly with the galvanizer to hot dip galvanize 500 tons of structural steel for the sand mining equipment, conveyors and processing. The utilization of the AGA Design Seminar during the design process helped to set up both the manufacturer and the galvanizer for success.

A large livestock trailer, located in Wharton, TX was honored with the Original Manufacturing Equipment award. Livestock trailers are used every day and subjected to considerable wear and tear from the animals and transport. Traditionally the trailers are painted, but the end user and manufacturer of this trailer was interested in a more durable and long-lasting coating. An enormous amount of drain and vent holes needed to be applied strategically to ensure the trailer could be dipped and coated successfully. Collaboration by the manufacturer and galvanizing representative was a huge benefit and will lead to more products being hot-dip galvanized.

On the morning of July 30th, 2018, outside of Eureka IL, Grainland Cooperative experienced a massive explosion due to a corn dryer catching fire. Due to the massive damage inflicted by the explosion, most of the facility needed repairs or complete replacement. Grainland and facilities like it help serve the massive agriculture industry and its reconstruction has been honored with the Food and Agriculture award. This project alone had more than 1,200 tons of galvanized steel. As the world population grows, the demand for more crops and higher yields is inevitable. This will create more demand for storage/merchandising facilities like Grainland which rely on hot-dip galvanized steel.

The unmatched durability and performance of hot-dip galvanizing is particularly well suited to the needs of the electrical and utility market. The 735-kV Chamouchouane–Bout-de-l’Île Transmission line won this years award for the Electrical, Utility, and Communication sector. The multi-year project used 33,000 tons of hot-dip galvanized steel. Once installed, these towers and substations will enjoy many decades of corrosion-free service life with essentially no maintenance. In fact, they will join an inventory of galvanized transmission structures still in maintenance free service, some now well over 100 years old.

With its aesthetic appeal, durability and sustainability, hot-dip galvanized steel has proven to be an excellent choice for construction projects of all shapes and sizes. To see more hot-dip galvanized steel projects including other submissions to the 2019 competition and past winners, please visit the AGA Project Gallery.

Contact AGA Marketing Coordinator Alison Walsh for more information, high quality images, or specific project articles.

Complete List of Winners, by Category:

| Category | Project | Location | Galvanizer(s) |

| Most Distinguished | Humber College Parking Garage | Toronto, Ontario | Valmont Coatings - Pure Metal Galvanizing |

| Lifetime Achievement | Riviere Cochon Gras Bridge | Perches, Haiti | V&S Amboy Galvanizing LLC; V&S Taunton Galvanizing LLC |

| Artistic | Bloom | Reno, NV | AZZ Galvanizing - Reno |

| Bridge & Highway | A Tale of Two Bridges | Montreal, Quebec | Corbec Inc. - Montreal |

| Building & Architecture | MacKimmie Tower | Calgary, Alberta | Daam Galvanizing - Edmonton |

| Civic Contribution | The Living Bridge | Portsmouth, NH | Duncan Galvanizing Corp. |

| Duplex Systems | Louis Armstrong New Orleans Airport | Kenner, LA | AZZ Galvanizing - Morgan City & Baton Rouge |

| Duplex Systems | Oregon Convention Center Parking Facade | Portland, OR | Zinkpower - Portland |

| Electrical, Utility, & Communication | 735-kV Chamouchouane- Bout-de-l’lle Transmission Line | Saguenay-Lac-St-Jean, Quebec | Corbec Inc. - Quebec City |

| Food & Agriculture | Grainland Cooperative | Eureka, IL | AZZ Galvanizing - Peoria |

| Industrial | North American Aggregates | Perth Amboy, NJ | V&S Lebanon Galvanizing |

| International | Triberg Eagle | Triberg, Germany | Wedge Group Galvanizing Ltd - South West Galvanizing Ltd |

| Original Manufacturing Equipment | Large Livestock Trailer | Wharton, TX | AZZ Galvanizing - Houston West |

| Recreation & Entertainment | The Flying Ox | Pigeon Forge, TN | AZZ Galvanizing - Nashville |

| Transportation | Calgary MAX Transit Shelters | Calgary, Alberta | Daam Galvanizing - Edmonton |

| Water & Marine | High Seas Log Flume | Ocean City, NJ | V&S Amboy Galvanizing |