Hot-Dip Galvanizing Slip Factor Summary

The AGAs slip factor study has been receiving a lot of attention recently as the staff works to finish up the final stages of research. Even under this scrutiny, there are still a lot of questions about where the study is going and what the end result is going to look like. This years TechForum included two presentations on the subject; giving updates on the AGAs previous results, goals for upcoming phases, and the results of a complimentary study by the University of Texas. The research and presentations are summarized here for galvanizers and specifiers interested in the results.

University of Texas study

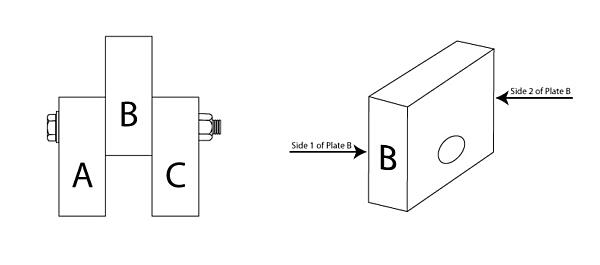

Todd Helwig, Ph. D., of the University of Texas, focused his research on the slip critical connections of galvanized surfaces. The study was designed to determine the slip coefficient of untreated galvanized surfaces, investigate the effects of several different parameters, and evaluate the effectiveness of current roughening procedures used in the industry.

Current industry standards based on historical data list the slip coefficient of galvanized surfaces as a Class A connection (? = 0.30). However, there was not an abundance of data to determine what variables in the galvanizing process affect this. The University of Texas investigated the variables of coating thickness, steel chemistry, chemical cleaning acid, variation among galvanizers, bath consistency, spinning, and surface roughening. Of these variables, steel chemistry (namely silicon content) affected the slip coefficient of galvanized surfaces most significantly. The slip coefficient of galvanized, reactive steel was plainly shown to be higher than that of a non-reactive steel. Other variables, spinning, coating thickness, and roughening did not prove to affect the results significantly.

Perhaps one of the most significant results of the research: roughening of the galvanized surface by wire brush or sanding did not consistently increase the slip coefficient between galvanized surfaces. This opposes previous understanding within the industry as some standards require a galvanized surface to be roughened to increase the slip coefficient and meet industry standards. Because of the studys results, removing the roughening requirement from the standard is being recommended to AISC and RCSC. The study also found a general increase in the slip coefficient of untreated galvanized surfaces. This indicates changes in the galvanizing process have led to an altered coating which yields a higher slip coefficient. These two discoveries from the research are being presented to AISC and have the potential to change the current standards for benefit of the galvanizing industry.

AGA Slip Factor Study

The AGAs study of the slip factor of galvanized steel is now focusing on raising the slip factor from the traditional Class A slip coefficient to the higher Class B. With a higher slip coefficient, designers will be able to use galvanized steel in applications previously not considered or decrease costs by using less connections. Previous phases of testing indicate that obtaining the required 0.50 slip coefficient through roughening or other treatments is not possible. Therefore, the testing is focused on the use of a zinc-rich paint over the galvanized surface to obtain the Class B slip coefficient.

Paint manufactures produce paints able to achieve the Class B slip coefficient when used over bare steel. However, there are several considerations that must be taken into account when applying these paints over galvanized steel. Previous phases of research have indicated methods that will properly prepare the galvanized steel for these Class B coatings and promote the amount of adhesion necessary for a slip critical connection.

The most recent phase of research was intended to be the final stage with a chemical surface preparation method and several paint options tested. However, the results were not what was expected and left the laboratory testing procedures used in question. Another phase of testing using the previous paint and prep methods is slated to occur in early 2015 with a new laboratory. The AGA staff believes the next phase of testing will prove to be fruitful and a large step toward the completion of the project. The end goal of the study is a guideline or specification with instructions on preparing a galvanized surface to achieve a Class B slip coefficient.