Inspection Test Article Weight and Surface Area

Why do I need part weight and surface area when evaluating bare spots for repair?

There is a common misconception that any bare spot less than 1” in width is repairable by the galvanizer. In reality, ASTM A123 lists multiple criteria regarding parts that can be repaired using the methods in ASTM A780: each area subject to renovation shall be 1 inch (2.54 cm) or less the narrowest dimension, while the total area for repair on an article can be no more than 0.5% of accessible surface area or 36 in2/short ton (22,500 mm2/metric ton), whichever is less. For expanded definitions and illustrations of these requirements, see related articles: Maximum Allowable Repair Size (A123) and Ensuring Conformance to ASTM A780.

Therefore, to determine whether the part can be repaired you will sometimes be required to estimate or calculate the surface area and weight of the entire test article to perform the necessary checks for total bare area in addition to measuring the individual bare spot. Additionally, there is an advantage in determining the surface area and weight of your test articles well before you run the parts. This practice will allow inspection personnel to more quickly and easily determine whether the measured bare area (or total bare area) is acceptable for repair at the galvanizing plant, or whether the test article must be sent for re-galvanizing. Documentation of the test article surface area weight and the bare area measurements can be a very valuable resource whenever your customer has questions regarding the specification requirements.

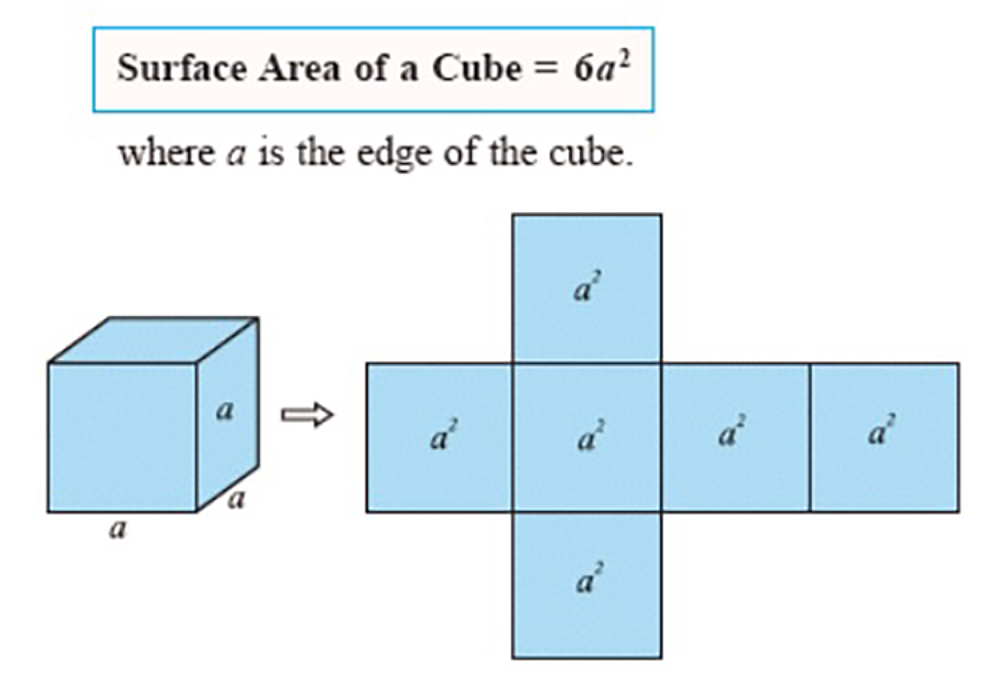

Start by obtaining the surface area of the inspection test articles. Surface area is defined as a measure of the total area that the surface of the inspection test article occupies (Figure 1). In hot-dip galvanizing, we refer to the “accessible” surface area, meaning the area which excludes internal or overlapping surfaces that cannot be readily inspected. For plates and other box shapes, calculating the surface area (ft3 or m3) involves adding up the area of each surface on the part:

Each square or rectangular area = (length, ft or m) x (width, ft or m)

AND

Surface Area = total of all the areas which makeup the part’s surface

Once you know the surface area, the weight of a steel product can either be weighed directly for a precise value or estimated by multiplying the surface area with the volume of steel:

Weight (lbs) = Steel Volume (ft3) x 490 lb/ft3

OR

Weight (kg) = Steel Volume (m3) x 7,850 kg/m3

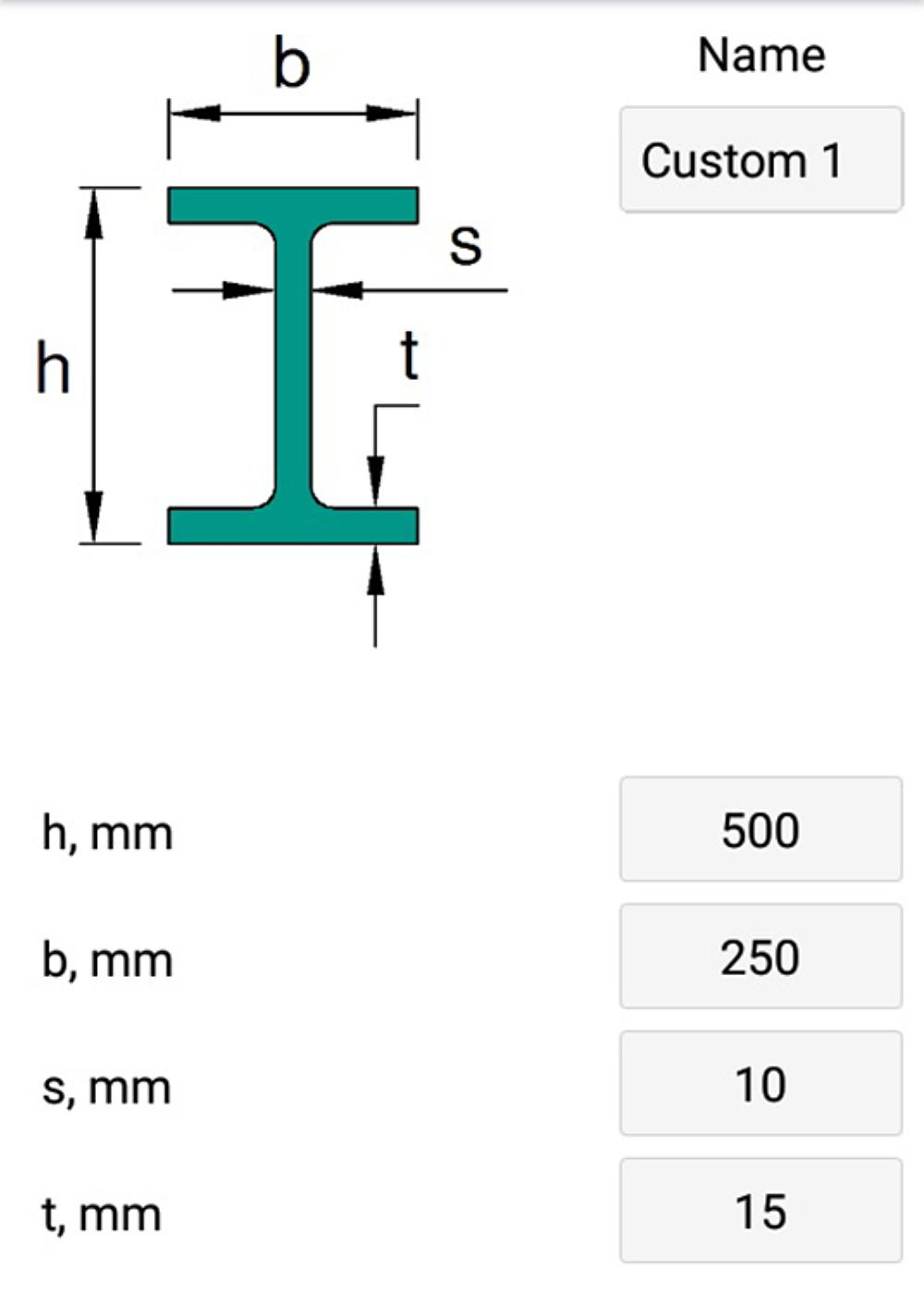

For more complex shapes, there are tools and equations to simplify the surface area, volume, and weight calculations. A popular smartphone app called Metal Calculator can calculate weight and surface area of structural products for you while on-the-go (beams, channels, tubing, etc.). Alternatively, product-Specific resources are available on the web from 3rd party suppliers and engineering resource sites to obtain surface area per foot and weight per foot:

- Angles

- Angles / ‘L’ Sections

- Wide Flange Beams (imperial)

- Wide Flange Beams (metric)

- I-beams (multiple designs)

- Universal Beams

- Universal ‘S’ Section Beams

- Taper Flange Beams, Channels and Junior Universal Beams

- Channels / ‘C’ Section Beams

- Custom Channel Dimension (weights only)

- External (Accessible) Surface Areas of Hollow Sections

- External (Accessible) Surface Areas of Circular Hollow Sections

Though there are many surface area formulas and tools available for standard products such as beams, angles, and tubing, other objects which are more complex (tanks or welded assemblies) require more detailed calculations. In such cases, it can be helpful to request the customer supply you with an engineering drawing or fabrication drawing containing the weight and/or surface area (calculated via CAD software) located in the notes or bill of material.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.