Stout Knife Testing

Tests for adhesion are subject to mutual agreement between the galvanizer and purchaser, and the adhesion test method for hot-dip galvanized coatings is provided in ASTM A123/A123M. This test method is commonly referred to as the stout knife test. However, A123/A123M does not state the number and frequency of tests, and this should be agreed ahead of time to eliminate confusion. To ensure the stout knife test is done without whittling, gouging, or applying excessive force to the galvanized coating, examples and a review of the stout knife test procedure are provided below.

The stout knife test should not be conducted without valid concerns of peeling, flaking, or an embrittled coating. Stout knife testing should also not be performed on edges or corners.

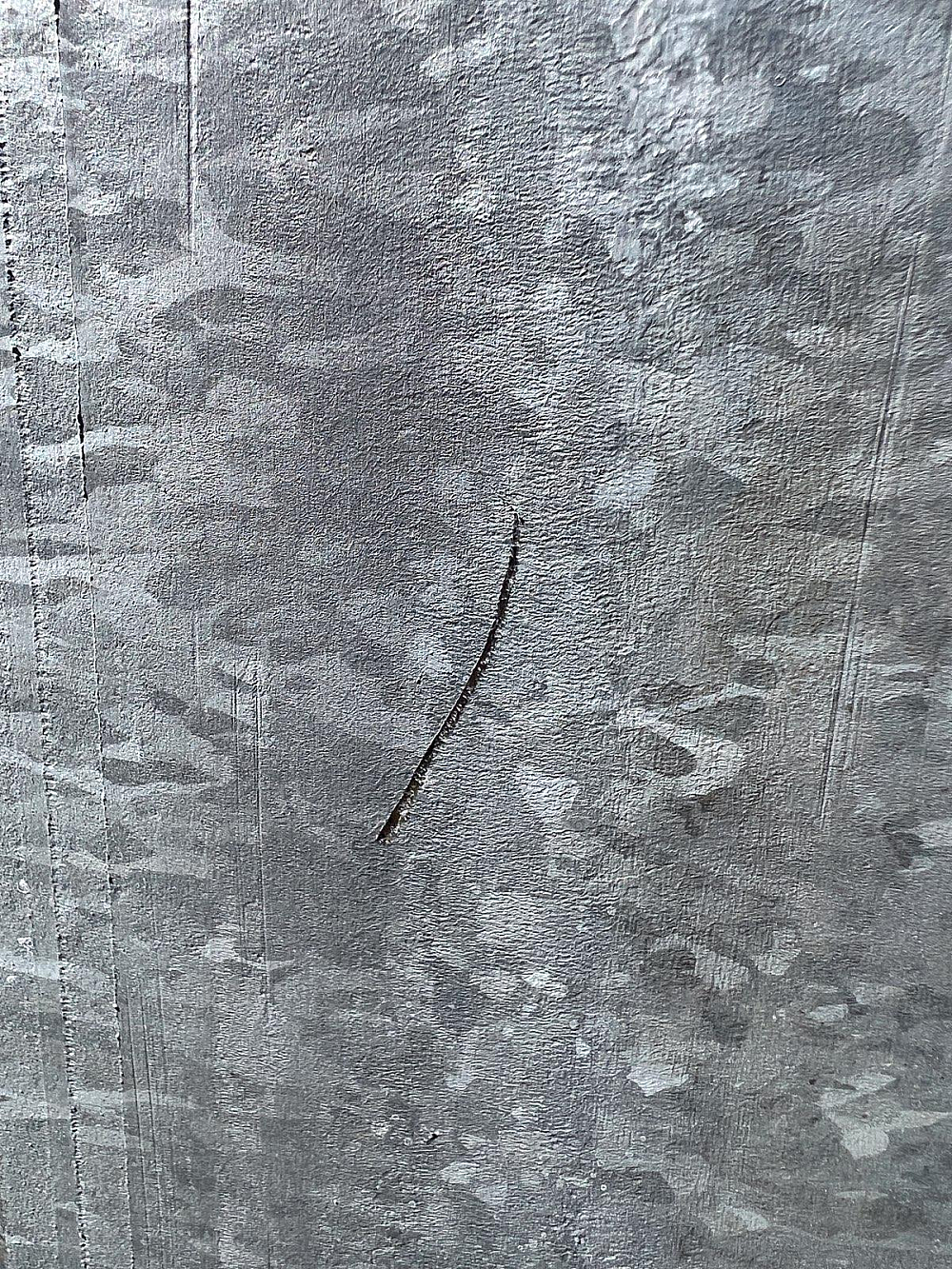

A123/A123M states, “Determine adhesion of the zinc coating to the surface of the base metal by cutting or prying with the point of a stout knife, applied with considerable pressure in a manner tending to remove a portion of the coating.” If a piece of the coating “flakes” off (see Figure 1) then the coating has failed the stout knife test. Figure 2 shows a coating that remained intact after a stout knife test, indicating adequate adherence.

You will need a sturdy, non-serrated blade knife to conduct a stout knife test safely and effectively. A knife sufficient for two hands is recommended, and if the knife is foldable, a locking blade is also suggested to prevent the blade from accidentally closing on the user’s fingers (see Figure 3).

First, firmly press the knife's blade into the coating, attempting to penetrate down to the substrate steel. When the blade is in contact with the steel, attempt to peel, or pry the coating off. Make only one clean, but firm attempt to peel a flake of coating free as in Figure 1. Do not whittle or hack at the coating. See below for a demonstration of the stout knife test performed in accordance with ASTM A123/A123M.

It is important to note although the stout knife test is the best indication of coating adherence, it may only offer limited information when attempting to determine if the coating will be susceptible to damage during abrasive (sweep blast) cleaning for preparing HDG for painting or powder coating. To best avoid coating damage during sweep blasting, it is recommended to utilize recommended abrasives and blasting procedures.

See Also:

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.