Abrasive Blast Media for Preparing HDG for Painting and Powder Coating

What abrasive media is used to prepare HDG for Painting/Powder Coating?

The most common method to prepare and roughen batch hot-dip galvanized surfaces for the application of industrial paint and powder coating systems (Duplex Systems) is sweep blasting in accordance with SSPC-SP 16 Brush-Off Blast Cleaning of Coated and Uncoated Galvanized Steel, Stainless Steels, and Non-Ferrous Metals. To prevent damage to the galvanized surface and achieve minimum surface roughness requirements, SP 16 gives recommendations for sweep blasting at a 30-60 degree angle with aluminum/magnesium silicate, soft mineral sands, soft crushed glass and glass bead media, and organic media such as corncobs or walnut shells.

However, blasting abrasives of low hardness (Mohs hardness <5) are not always effective at producing significantly roughened surfaces. Such structures are often recommended by the manufacturers of industrial coating systems where profile height requirements of 2.0–2.5+ mils are not uncommon. Paint and powder coating applicators have instead turned to a wide variety of harder abrasive materials available in the marketplace to achieve these profile height requirements.

To assist the specifiers and applicators of Duplex Systems, the AGA set out to evaluate successful sweep blasting methods with harder media and minimal coating damage. Abrasives such as crushed glass, garnet, proprietary low-silica sand mixtures, coal slag, and steel grit were evaluated.

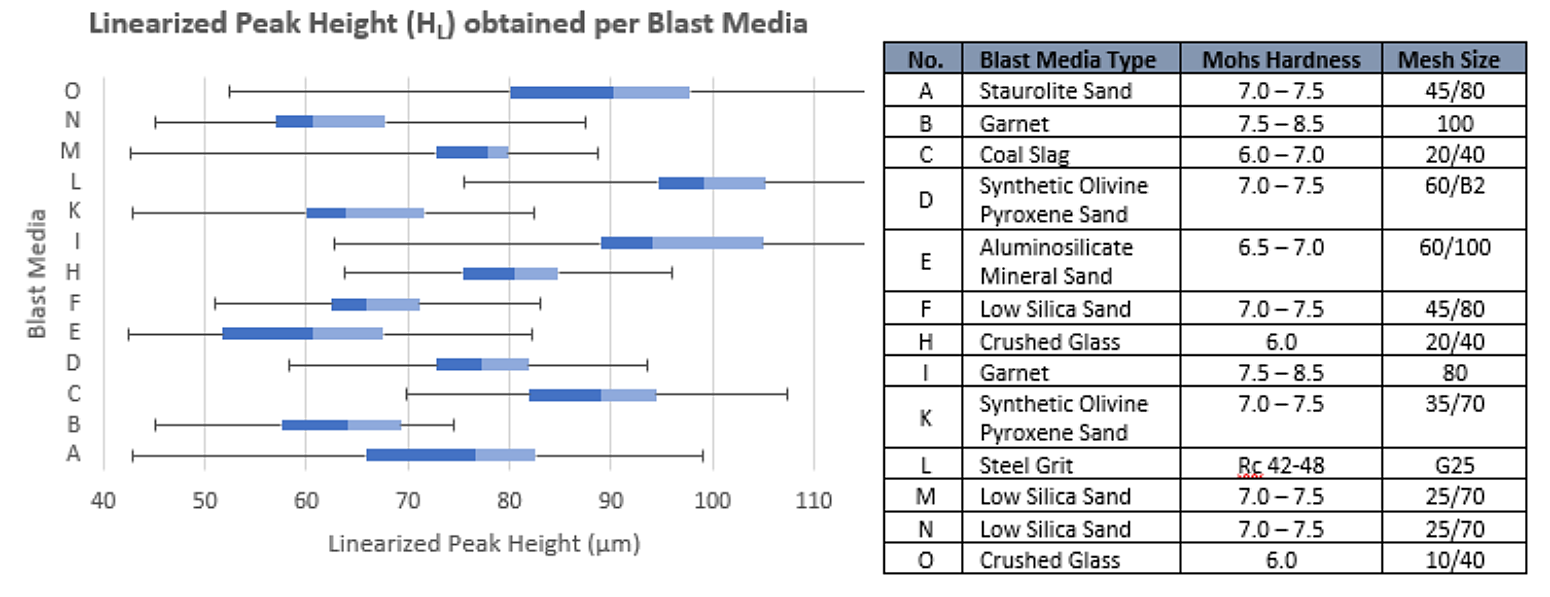

Generally, the study found sweep blasting with abrasive media of Mohs hardness five or greater is capable of producing roughened galvanized surfaces with increased peak heights (2.0+ mils), but additional mitigations by the blaster may be necessary to significantly reduce risk of damage. These methods may include increased stand off distance, lower pressure, faster nozzle movement, or use of finer media. The following chart summarizes the capability of a particular blast media to achieve a certain value for peak height when used to sweep blast hot-dip galvanized surfaces in preparation for painting or powder coating.

In addition to average maximum peak to valley height, areal peak density (peaks/mm2) and the presence of coating damage were evaluated for each blast media used to sweep blast galvanized steel with various blast settings: These parameters are associated with a potential impact on the performance or adhesion of a liquid coating system when applied over a galvanized surface.

Specifiers may also consider the impact of a potential reduction in coating thickness (0.4 – 0.6 mils) found to occur when sweep blasting with the harder media. Practically speaking, most Duplex Systems are maintained for the purpose of aesthetics, and the overall coating system will last indefinitely as the base galvanizing is rarely exposed. In such cases where the paint or powder coating of a Duplex System will be maintained, the potential reduction in coating thickness is likely acceptable.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.