Vent/Drain Holes for Tubular Articles with Many Parallel Components

How can I keep fabricated pipework from floating in the bath?

When fabricated pipework designs contain five or more horizontal components or rails, galvanizers often report these products can have a tendency to float within the zinc bath if provided standard vent and drain hole details. Floating structures cause headaches for the galvanizer because these articles are difficult to handle safely in the galvanizing kettle, experience longer-than-normal processing times, and often result in poor galvanizing quality. To mitigate against floating, additional venting and drainage holes are needed to improve the flow of zinc within the fabrication.

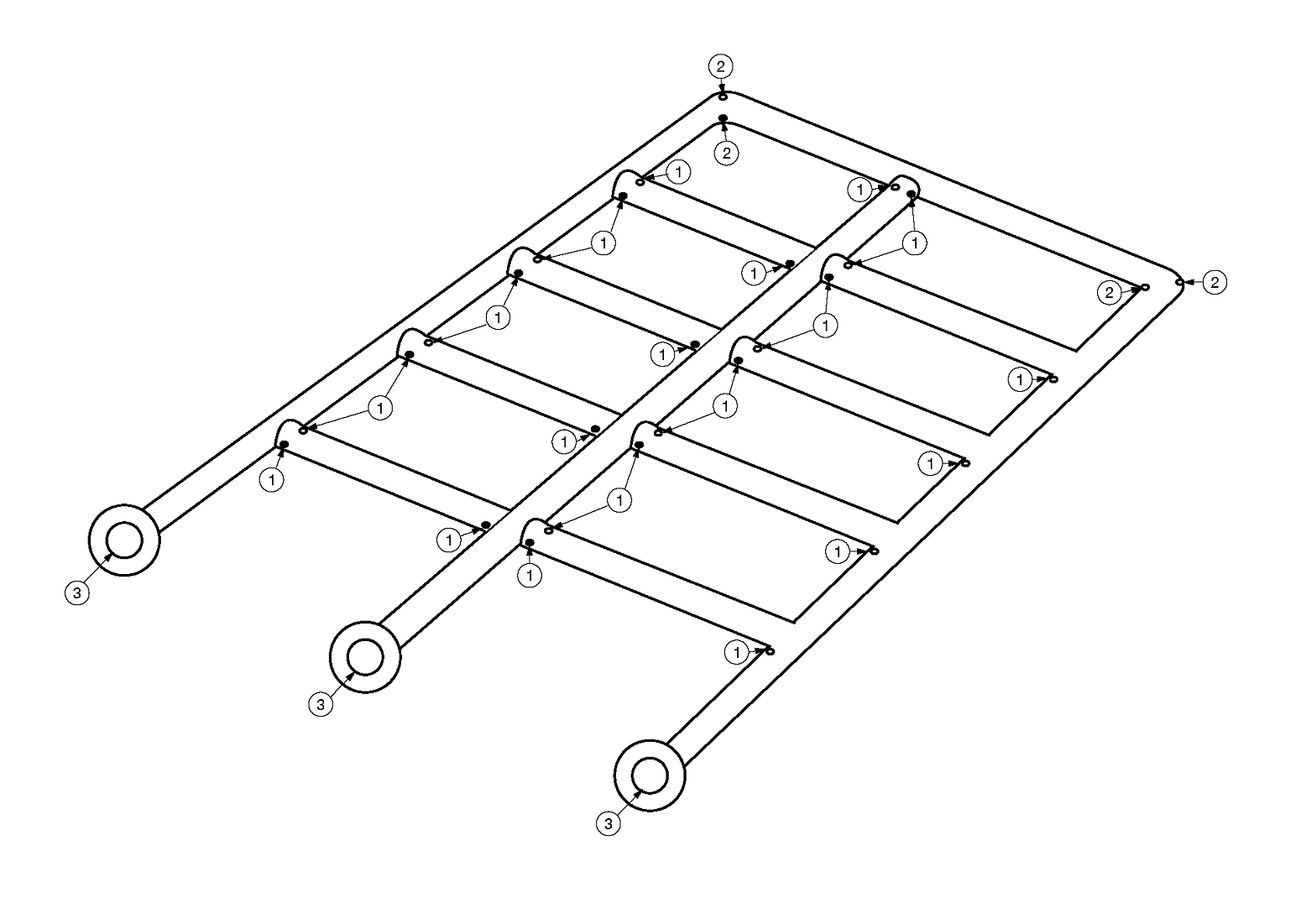

To describe one example, see below drawing from the 2020 revision of ASTM A385, Practice for Providing High-Quality Zinc Coatings (Hot-Dip). This drawing illustrates desirable design features for fabrication of handrail containing five or more rails to prevent issues with floating. External vents should be provided with one vent hole in each side of the internal intersections.

For clarity, the following notes provide additional information regarding placement and sizing of the venting/drainage holes:

- Each vent hole shall be as close to the weld as possible with the edge of the hole less than 0.5 in [12 mm] from the edge of the weld bead, and not less than 3/8 in. [9.5 mm] in diameter. The two holes at each intersection shall be 180° apart and in the proper location as shown.

- Vent holes in end sections or in similar sections shall be at minimum ½ in. (12.7 mm) in diameter, but may be considered optional depending on lifting orientation during galvanizing or to achieve higher coating quality.

- Any device used for erection in the field that prevents full openings on vertical legs shall be attached after galvanizing.

- Vent holes shall be visible on the outside of any pipe assembly prior to hot-dip galvanizing.

If necessary to seal or hide the vent/drain holes after hot-dip galvanizing, it is most common to use zinc or aluminum plugs for this purpose. They are tapered so they can be hammered in and then filed down smooth.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.