Rough Surface Condition Due to Steel Laps

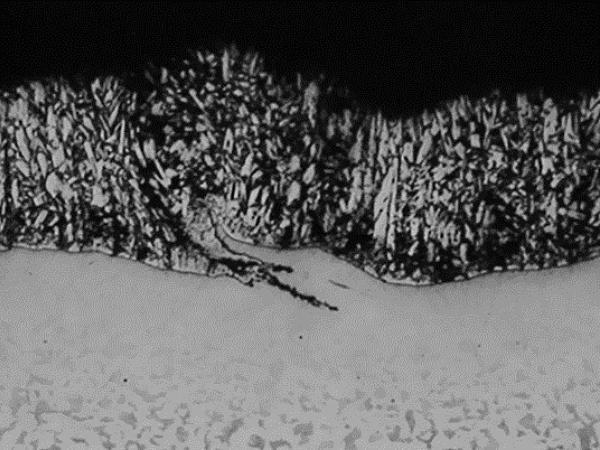

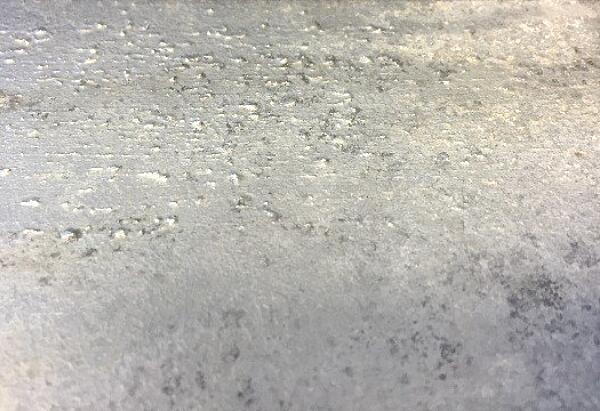

Members of the American Galvanizers Association (AGA) in the Pacific Northwest region are currently experiencing a surface condition identified as laps in the steel surface (Figure 1) which present themselves as sharp, raised spikes after hot-dip galvanizing (Figure 2). These laps tend to be present on hot-formed semi-finished products, including flat bar, round/square stock, angle and channel.

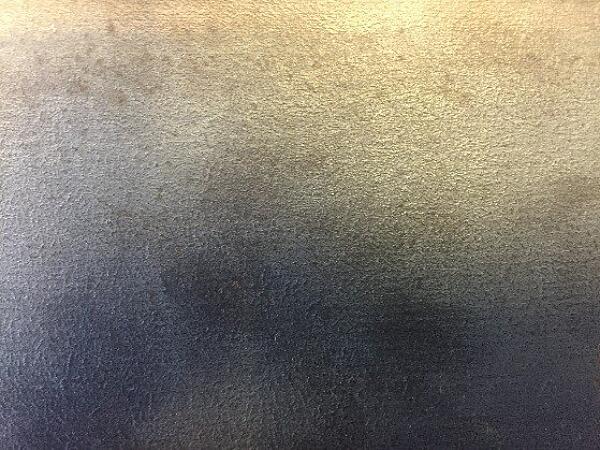

This surface condition is very difficult to identify prior to galvanizing (Figure 3). Even if laps are detected, alternative pre-treatments such as extended chemical cleaning times and mechanical cleaning (abrasive blasting, wheel abrading) before galvanizing have not proven a successful solution for remedying the steel surface.

Because the raised spikes contain steel within, attempts to remedy the spiked appearance after galvanizing are often not feasible without exposure of bare metal. The bare areas experienced after smoothing can be repaired where practical using a galvanizing repair compound, or due to the small surface areas involved the surrounding zinc can provide cathodic protection to these areas with only a minor impact on overall corrosion protection.

As the presence of laps in the steel surface is not within the control of the galvanizer, nor easily detected and remedied by available methods in the batch galvanizing process, the galvanizer cannot be held responsible for smoothing and repairing surfaces with this condition after hot-dip galvanizing.

The AGA and affected galvanizing members are involved in an ongoing investigation to address the issue at the point of steel manufacturing. Meanwhile, the AGA is also investigating additional methods to detect laps and remedy the surface of these products. Until such methods are developed, customers wishing to galvanize hot-formed semi-finished products should investigate the source(s) and manufacturer(s) of products susceptible to this condition, and be mindful of the additional time/cost for remediation and impact to corrosion resistance that may be possible. This is especially true for applications where the affected products will be duplexed or used for railings.

The AGA developed the following letter which may be distributed to customers experiencing this surface condition.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.