Bridge Washing Impact on Life-Cycle Cost

Bridges can be subjected to factors like poor drainage, heavy road deicing, or environmental influences that can contribute to accelerated corrosion. One preventative solution utilized by bridge owners is to periodically remove the debris and wash bridges off with water. This removes damp vegetation and clears away chlorides leftover from road salting.

Bridge washing is usually performed annually or on a 2-5 year cycle. Clean, fresh water used at various pressures to remove sand, dirt, gravel, dead vegetation, pollution, and chlorides/de-icing agents. Spring is the typical time of year for bridge washing as residual de-icing agents from the winter are removed. Despite limited empirical data, DOTs who perform bridge washing report it is beneficial and extends the service life of all bridges exposed to de-icing agents. Further, NSBA’s Uncoated Weathering Steel (UWS) Reference Guide formally recommends bridge washing depending on the environment and use of de-icing materials: “washing and cleaning of UWS components should be part of a larger bridge preservation program”. See also AGA’s article HDG vs. Uncoated Weathering Steel (UWS).

Table 1: Maximum Water Pressure for Washing Types of Steel Bridges

UWS |

6,000 PSI |

HDG |

1,450 PSI |

Painted Steel |

Contact paint manufacturer |

In North America, bridge washing programs are more common in the Northeast and Midwest regions where de-icing agents are more frequently used. While washing usually focuses on decks, bearings, and drainage systems, it is occasionally extended to include girder-ends and substructures. As of 2024, twenty two DOTs report they perform bridge washing. Of these, only seven of those DOTs report washing more than 50% of their bridges.

If needed, it is possible to consider the relative impact of these maintenance costs in a life-cycle cost analysis. Although there is no industry consensus on the cost of sweeping and bridge washing, a mixture of anecdotal reports and public records indicate the cost for third-party services is approximately $1/sq-ft of deck area. When utilizing internal maintenance crew teams, sweeping and bridge washing average costs are reported to be lower such as approximately $650/bridge.

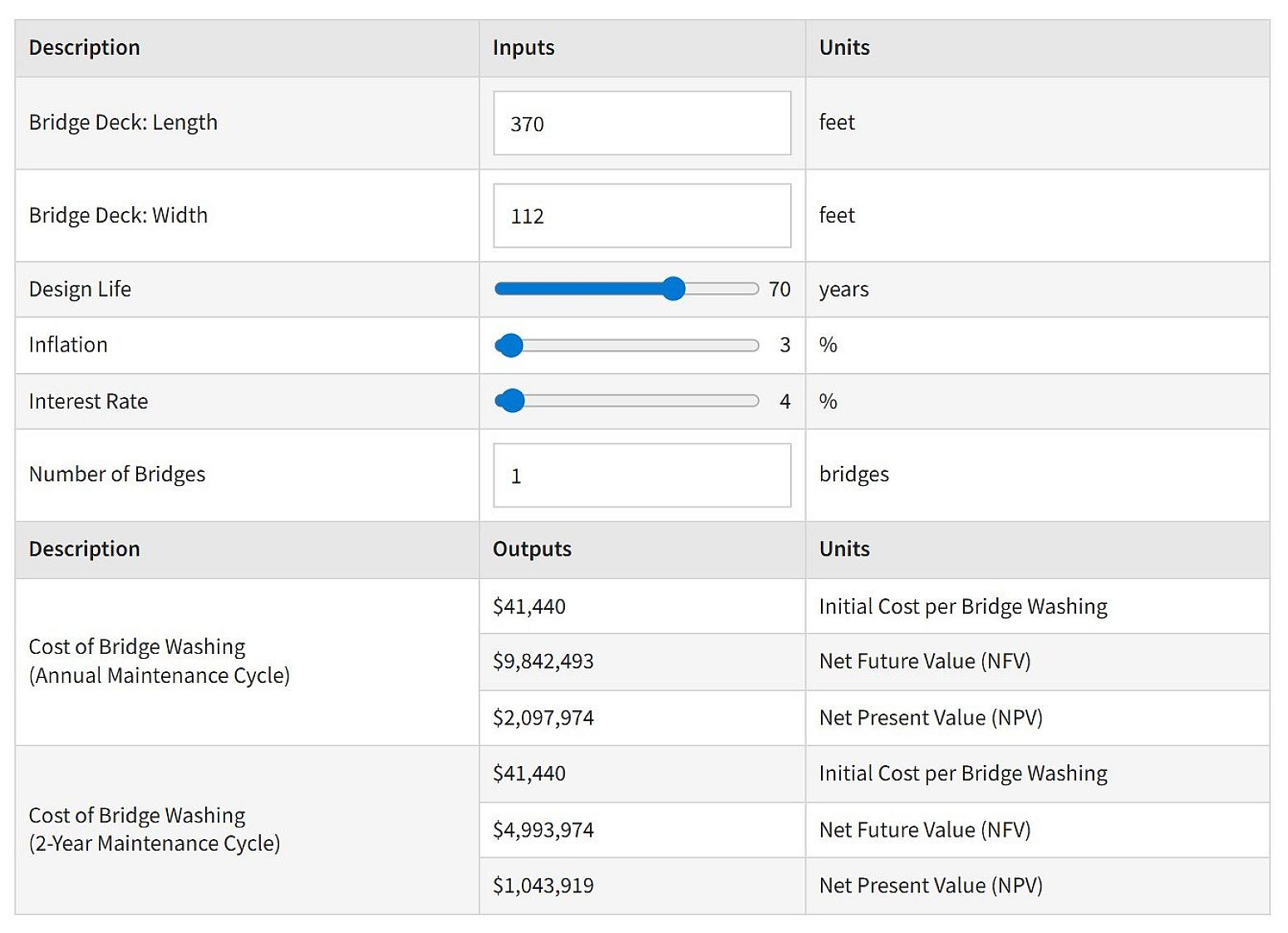

To assist in calculating the relative impact of bridge washing recommendations on life cycle cost, the AGA offers a new cost calculator which considers the bridge size and two different maintenance cycles.

Example Bridge

For projects where bridge maintenance costs are considered, obtain information about the specific bridge deck size and design life for a quick analysis. If analyzing a bridge bundling project (assuming multiple bridges similar in design and size), it is recommended to identify the average bridge deck size and quantity of bridges. Afterwards, results from the bridge washing calculations can be used to demonstrate costs over the life-cycle when accounting for annual or biannual washing.

In this generic example, the cost of each bridge washing maintenance activity is approximately $41,440 (in today’s dollars) assuming the use of third-party contractors. It is assumed many bridge owners outsource this maintenance activity, but not all. Over a design life of 70 years, the cost of annual sweeping and washing increases the life-cycle cost by approximately $2.1 million in today’s dollars.

© 2025 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.