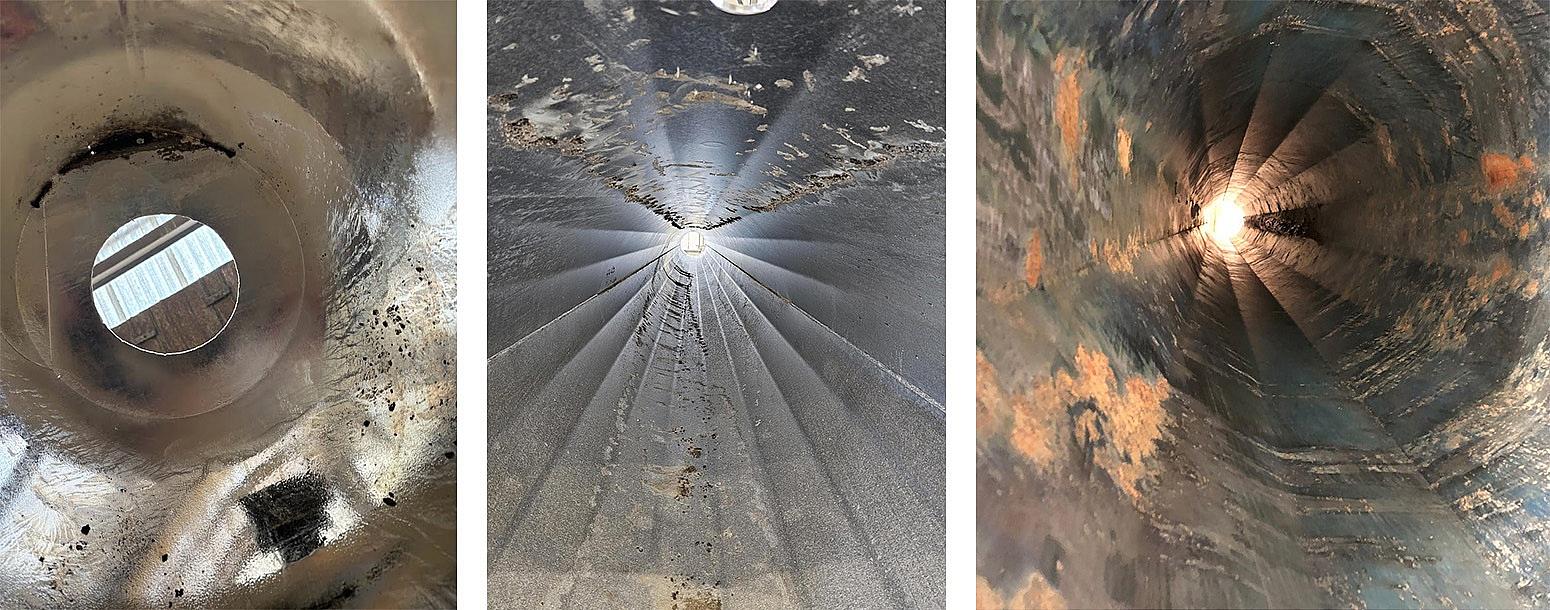

Skimmings Inside Hollow Structures

Are Skimmings Trapped Inside Hollow Structures Like Poles Rejectable?

Hot-dip galvanizing (HDG) skimmings are natural by-products of the hot-dip galvanizing process. Ashen in appearance and comprised of zinc oxides, zinc chlorides, and zinc metal, skimmings deposits are typically formed when there is no access to remove or allow skimmings to escape during the withdrawal of steel from the galvanizing kettle. Specific to internal surfaces, this can occur when vent holes are not adequately sized, or if the galvanizer is unable to maintain a steep lifting angle for galvanizing due to the product’s length. Skimmings on the surface of the molten zinc bath are then carried away and trapped on the surface of the zinc coating.

While skimmings may detract from the appearance of the galvanized surface, they are superficial and do not affect the performance of the underlying zinc coating. ASTM A123 explicitly states skimming deposits are not grounds for rejection, as they do not compromise the corrosion protection.

6.2 Finish

[…] Zinc skimmings (zinc oxide and zinc chloride particulates from the top surface of the zinc bath) may cling to the coating surface after the part is removed from the zinc bath. These zinc skimmings are not cause for rejection as the coating beneath these skimmings is intact and will provide the anticipated corrosion protection. Some zinc skimmings can be brushed off the surface or will be washed off in the rain or condensation that gathers on the part as it weathers in the atmosphere. Other zinc skimmings may need to be ground off the surface of the coating by the galvanizer without removing zinc to the point that the coating no longer meets the minimum thickness requirement. […]

Skimmings can be removed to inspect for the presence of a galvanized coating in a local area or enhance the aesthetic appeal of the galvanized product. For external surfaces, this can be achieved using a nylon bristle brush, wire brush, or a hand grinder. However, when employing a grinder, caution must be exercised to avoid removing too much of the zinc coating. Fabrications such as tanks, poles, pipes, and tubes, may accumulate skimmings on internal or inaccessible surfaces where their removal is impractical or impossible. Again, skimmings trapped on internal surfaces are still not grounds for rejection.

Skimmings are a natural outcome of the galvanizing process, and their presence is accounted for within ASTM A123 guidelines. They are not grounds for rejection and do not diminish the durability or performance of the galvanized coating. While they can be removed for inspection or aesthetic purposes on accessible surfaces, removal is often unnecessary and impractical for internal or inaccessible areas.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.