Natural Weathering & Zinc Repairs

What Touch-up & Repair Materials Weather Naturally with the HDG Coating?

Although galvanized coatings are highly abrasion resistant, coating damage may occur once the galvanized steel leaves the galvanizer’s facility due to extremely rough handling, installation techniques, welding after galvanizing, or in-service conditions. These exposed areas of steel require repair of the hot-dip galvanized coating to protect the steel and ensure the integrity of the coating.

ASTM A780, Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings, discusses the use of three different materials for repairing these damaged or uncoated areas: zinc-rich paint, zinc-based solder, or zinc-spray metallizing. The use of touch-up materials can alter the initial appearance of the galvanizing finish as they are not usually an exact color match. Although differences in appearance from the use of touchup materials is acceptable and not grounds for rejection, selection of repair material can be considered when aesthetics are a primary concern.

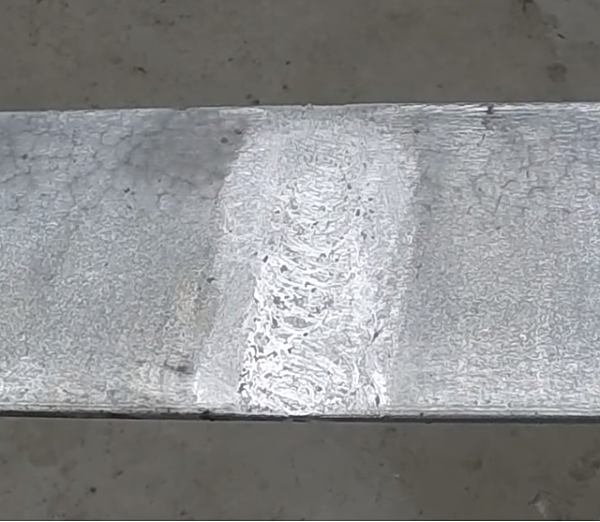

In terms of appearance, zinc-based solders (Figure 1) and zinc-spray metallizing (Figure 2) will more closely match the appearance of hot-dip galvanized steel and will weather similar to the base galvanizing. However there are limitations to applying both materials which must be considered in addition to cost.

Because the galvanized steel surface will weather and become a matte gray color over time (6 months to 2 years in the environment), zinc-rich paints can eventually provide a uniform aesthetic if a matte gray or weathered color repair paint is utilized. Although the appearance may at first be a mixture of gray paint and shiny hot-dip galvanizing (Figure 3), all hot-dip galvanized coatings will weather to a matte gray and more closely match the repair paint color over time. Touch-up performed using bright/shiny zinc-rich paint (Figure 4) will not weather in color similar to the surrounding coating, and will therefore result in permanent mixed appearance once the base galvanizing weathers. If required for aesthetic purposes, top-coating of the touched-up area with aluminum or bright/shiny spray-applied paint products can be used to color-match newly galvanized steel.

To assist in selection of repair materials, AGA has an updated list of HDG repair material suppliers along with the primary repair products available. Some of the AGA zinc-rich paint suppliers offer shiny repair paint, matte/weathered color paint, or both.

Touch-Up & Repair Material Suppliers 2019

See also:

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.