Considerations For Bending Steel Reinforcing Bar Before and After HDG

Should Steel Reinforcing Bar Be Bent Before or After HDG?

Hot-dip galvanized (HDG) steel reinforcing bars can either be bent prior to galvanizing or after the coating has been applied. Regardless, there are considerations the designer and/or specifier should review to determine whether bending before or after hot-dip galvanizing is preferred for a particular application.

Bending Reinforcing Bar Prior To HDG:

When bending rebar prior to hot-dip galvanizing, it is recommended the bend diameter be as large as possible in order to avoid strain-age embrittlement from excessive cold forming of the steel. When rebar is cold-bent, stresses are induced into the steel. Later when the rebar is heated to the temperature of the galvanizing kettle, the change in temperature can affect the areas with the increased stress from cold working. When the stresses from the cold bending are excessive, it is possible for strain-age embrittlement to occur.

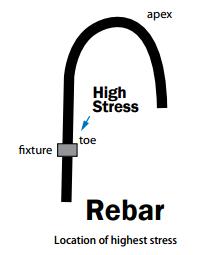

Besides cold working, another factor that contributes to strain aging is steel quality. Rebar is more susceptible to strain-aging because it is commonly made from lower quality steel, containing many impurities that congregate at the highly stressed points in the steel. As a result, strain-aging and fractures are more likely to occur at the toe of the bend where the highest induced stress resides.

The large bend diameters recommendations limit the amount of stress introduced to the steel during cold working and decrease the chances for stain-age embrittlement. ASTM A767/A767M Table 2 provides guidelines for the recommended bend diameter based on the nominal bar size.

| Minimum Finished Bend Diameters (ref. ASTM A767 Table 2) | ||||

|---|---|---|---|---|

| Bar No.

Imperial [Metric] | Grade 40

[Grade 280] | Grade 50

[Grade 350] | Grade 60

[Grade 420] | Grade 75

[Grade 520] |

| 3, 4, 5 [10, 13, 16] | 6d | 6d | 6d | ... |

| 6 [19] | 6d | 6d | 6d | 6d |

| 7, 8 [22, 25] | 6d | 8d | 8d | 8d |

| 9, 10 [ 29, 32] | … | … | 8d | 8d |

| 11 [36] | … | … | 8d | 8d |

| 14, 18 [43, 57] | … | … | 10d | 10d |

Note: d = nominal diameter of the bar.

By following the bend diameter recommendations, the bend process produces much lower residual stress levels. If rebar is required to be bent tighter than these recommendations, it can be stress relieved at 900 F to 1050 F (480 C to 560 C) for one hour per inch of bar diameter to reduce the residual stress.

Bending Reinforcing Bar After HDG

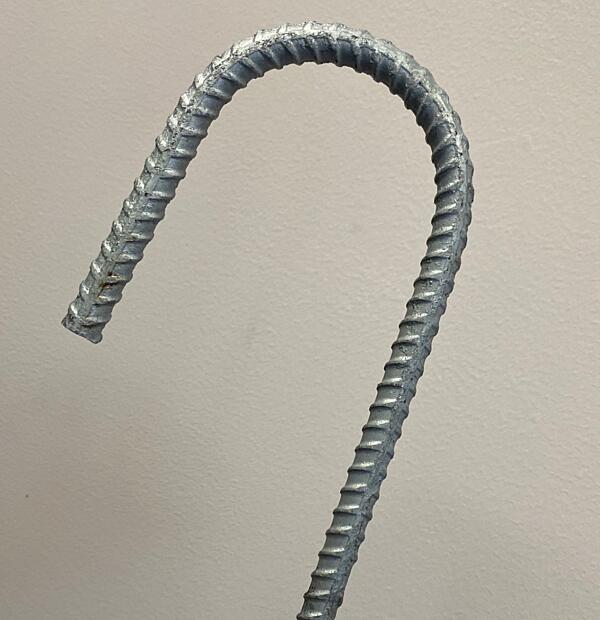

When hot-dip galvanized rebar is bent after the hot-dip galvanizing process, there is no concern with strain-age embrittlement, and therefore bend diameter is not limited in any way. Upon bending, some thicker galvanized coatings such as ASTM A767 Class I can experience increased potential for cracking or flaking of the coating in the area of the bend. Hot-dip galvanized rebars with coatings less than 4 mils ( 100 microns) develop coatings that will not crack or flake when bent after galvanizing. Contact your local galvanizer for more information regarding the various methods to minimize damage when bending after HDG.

If flaking in the bend area is a concern, it can be greatly minimized by utilizing slower bend speeds and maximizing the bend radius where possible. Should cracking or flaking occur, the damaged coating can be repaired easily in accordance with ASTM A780/A780M and is not grounds for rejection per ASTM A767/A767M Section 7.2.1:

- 7.2.1 When galvanizing is performed before bending, some cracking and flaking of the galvanized coating in the area of the bend shall not be grounds for rejection (Note 7).

- Note 7 The tendency for cracking of the zinc coating increases with bar diameter and with severity and rate of bending.

Although the damage in bend areas can be repaired by the methods described in ASTM A780/A780M, it is not recommended to heat the bend areas with a torch to perform a repair using zinc solder. This can potentially strain-age the steel due to the elevated temperature of the torch.

Which is Best - Bending Reinforcing Bar Before or After HDG?

When hot-dip galvanizing rebar in straight lengths, later fabrication can result in cut ends, bends, and welds. These areas may require touch-up of the coating, but touch up of these areas is relatively simple. Bending after hot-dip galvanizing also provides advantages with respect to design: there are no minimum bend diameters, the material can be coated in advance for availability/inventory purposes, and large or complex rebar fabrications which may not fit within the dimensions of the galvanizing kettle can be constructed.

Although it is simple to repair small areas of the coating in accordance with ASTM A780/A780M, there are certainly advantages to fabricating prior to hot-dip galvanizing. More complex reinforcing cages for beams, columns, or foundations can be fabricated in advance so that repairs for bend, cut, and weld areas are eliminated. Although minimum bend diameters are recommended to avoid strain-age embrittlement, it is possible to bend rebar tighter than recommended. However, additional work to stress relieve the bend areas will be required.

When in doubt, be sure to discuss the hot-dip galvanizing of rebar and rebar fabrications with the galvanizer during the design phase of the project.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.