Choosing Between Foreign & Domestically Sourced Steel

Based on price alone, it could be enticing to source steel from foreign suppliers. However, it is important to look beyond price and consider other factors when sourcing steel. In this article, we will discuss the key factors of cost, quality, availability and sustainability when comparing foreign and domestically sourced steel. We will also address concerns with hot-dip galvanizing foreign versus domestically sourced steels.

Costs

Historically, foreign steel has often been perceived as cheaper due to lower labor and production costs in certain countries. However, it is important to consider the additional costs associated with importing steel, such as tariffs, customs duties, shipping fees, and potential delays at customs. These extra expenses can impact the overall cost-effectiveness of foreign steel. Domestically sourced steel may have higher upfront costs but can provide greater stability and reduced logistical complexities.

Quality

Steel quality is a crucial consideration as it directly affects the durability, strength, and performance of the final product. Domestically sourced steel adheres to stringent quality standards and regulations set by local authorities. Buyers can have greater confidence in the consistency and reliability of domestically sourced steel, as it is subject to quality control measures and certifications. However, this is not to say that foreign steel is inherently of lower quality. Many foreign steel producers and galvanizers have implemented quality control measures to meet international standards, and some even exceed domestic quality benchmarks. Conducting thorough research on the reputation and track record of foreign suppliers can help ensure the procurement of high-quality steel.

When considering to hot-dip galvanize foreign steels, be aware some foreign steel producers are known to have inaccurate steel chemistry analyses on the mill reports. The chemical composition provided in the mill test report is used to make an evaluation of the steel reactivity which affects galvanizing quality. When the mill test report cannot be trusted, a galvanizer may have to run test sample for confirmation (leading to potential delays), or sometimes it may be determined the steel is not suitable for galvanizing.

Availability

Availability of steel is influenced by factors such as domestic production capacity, global demand, and trade agreements. Domestically sourced steel benefits from proximity, allowing for faster delivery times and reduced lead times. In times of increased demand or supply disruptions, relying solely on domestic sources can provide a more stable supply chain. However, the globalization of the steel industry has expanded access to a wide range of foreign steel suppliers, offering a diverse selection of products and specifications. It is essential to assess market conditions, lead times, and supplier reliability when considering the availability of both foreign and domestic steel.

Sustainability

Foreign versus domestically sourced steel should also be evaluated on sustainability. The transportation of steel over long distances can contribute to carbon emissions and environmental impacts. While domestically sourced steel generally has a lower carbon footprint due to reduced transportation distances, it is important to note sustainability in steel production extends beyond transportation. Factors such as the energy efficiency of steel mills, recycling practices, and adherence to environmental regulations also play a significant role in determining the overall sustainability of steel sourcing. Therefore, it is crucial to assess the sustainability practices and certifications of both foreign and domestic steel suppliers to make an informed decision.

Importing Fabricated Hot-Dip Galvanized Steel

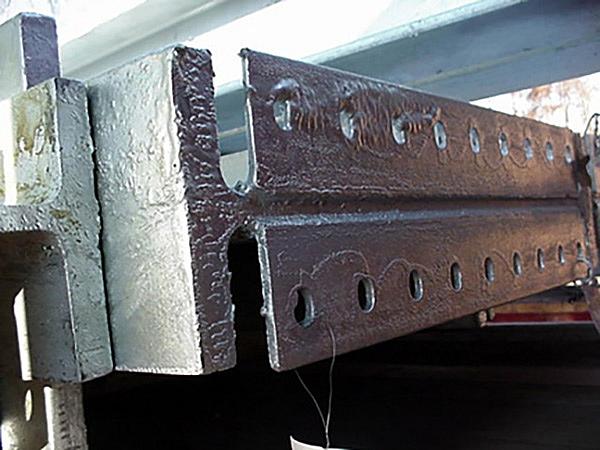

One may also consider procuring fabricated hot-dip galvanized (HDG) steel directly from foreign suppliers. With regards to costs, quality, availability, and sustainability, the same factors mentioned above for black steel should be considered. It is also important to inspect the HDG steel upon arrival to ensure complete coating coverage and sufficient coating thickness has been achieved. In situations where poor quality is observed, the steel may need to be re-galvanized to ensure it provides adequate service life.

It is also important to consider the transportation required for import. Shipping newly hot-dip galvanized steel overseas can create an environment that leaves newly galvanized steel uniquely vulnerable to the formation of wet storage stain (WSS). The usual methods for WSS prevention are recommended, however, the maritime environment and seawater can create circumstances that are difficult to mitigate using a conventional approach. Best practice is to keep the galvanized products dry and with adequate airflow, but salty, humid air combined with the risk of direct contact with sea spray complicates this normally simple endeavor.

Passivation is another potentially effective prevention method for WSS, but when used for an extended time at sea, protection provided by passivation can be limited. The effectivity of passivation multiplies when combined with other methods of WSS mitigation such as proper stacking to promote free flowing air and water/moisture drainage.

It is important to note that WSS typically results in minimal zinc coating thickness loss and will not have a significant effect on the coating life, but its appearance is primarily an undesirable aesthetic concern for some users.

Summary

The decision to source steel domestically or from foreign suppliers depends on a variety of factors, including costs, quality, availability, and sustainability. While foreign steel may offer potential initial cost savings, it is essential to consider the additional expenses associated with imports. Domestically sourced steel often provides higher quality due to adherence to local regulations, but foreign steel suppliers can also meet international standards. Availability considerations require assessing factors such as lead times, market conditions, and supply chain stability. Ultimately, a balanced evaluation of these factors and careful consideration of specific project requirements are essential in making an informed decision on sourcing steel.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.