Estimating The Life Of Hot-Dip Galvanized Coatings

Before I decide to use hot-dip galvanized steel on my project, I would like to know how long its going to last. Is there a good way to approximate longevity of galvanized steel?

As is the case with any corrosion protection system, the two most common questions about hot-dip galvanizing are in reference to the life of the coating and the costs associated with using it. Fortunately, the American Galvanizers Association has developed a tool that allows specifiers to quickly reference a visual guide that approximates the corrosion protection performance of hot-dip galvanized steel in atmospheric conditions.

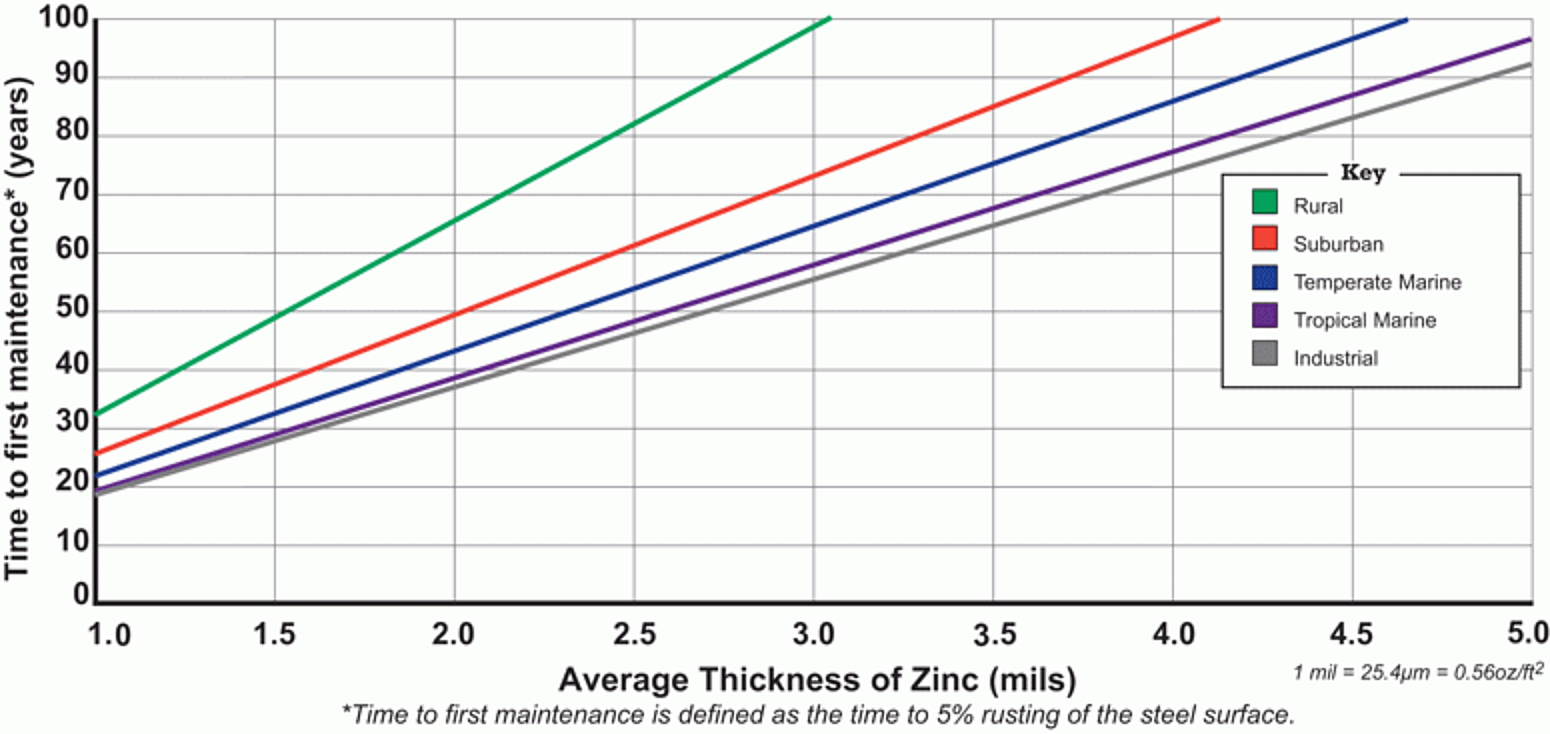

The Time to First Maintenance Chart depicts the estimated time to first maintenance for a zinc coating against the thickness of the coating in atmospheric applications. This chart is not applicable to estimations of coating life in soil or water. The chart features five distinct plotlines representing climate types with varying corrosion rates. With these plotlines and knowledge of the thickness of your coating, estimating the time to first maintenance of a hot-dip galvanized coating is as simple as reading a few points on a graph.

Using the Time to First Maintenance Chart

Specifiers generally use the Time to First Maintenance Chart to estimate the life of a hot-dip galvanized coating. The chart shows a time to first maintenance of the coating (vertical axis) vs. the thickness of the coating (horizontal axis). Therefore, simply finding the horizontal line where the projects corresponding climate type line intersects the vertical line representing the coatings thickness will indicate an estimated time to first maintenance.

Therefore, to estimate time to first maintenance, you will need to know the thickness of the coating and the climate where the project will be located. While it is not possible to specify an exact thickness of a hot-dip galvanized coating, North American galvanizers will meet the requirements of ASTM A123 Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. Table 1 of the standard contains requirements for minimum average coating thicknesses on various steel products. A quick look at this table tells specifiers what thickness is required under ASTM A123. For larger structural steel pieces (1/4 inch thick or greater), the minimum average coating thickness under ASTM A123 is 4.0 mils, but coating thickness averages often exceed these minimums and will usually be in the 3.9 to 5.0 mil range. To determine which climate the project is located in, it may be helpful to compare the climate of the area in question with the example cities used to generate the chart. Below is a table containing the cities used as examples in each climate

Time to first maintenance is NOT equal to the service life of hot-dip galvanized steel. The time given by the chart indicates when five percent of the steel surface will be rusted. At that point, there will still be galvanized coating on a majority of the steel, but it will need to be repaired. This can be done through repairing the rusted areas with paint or re-galvanizing the surface entirely. If maintenance is performed at this time, the service life of the steel will be dramatically increased.

Example

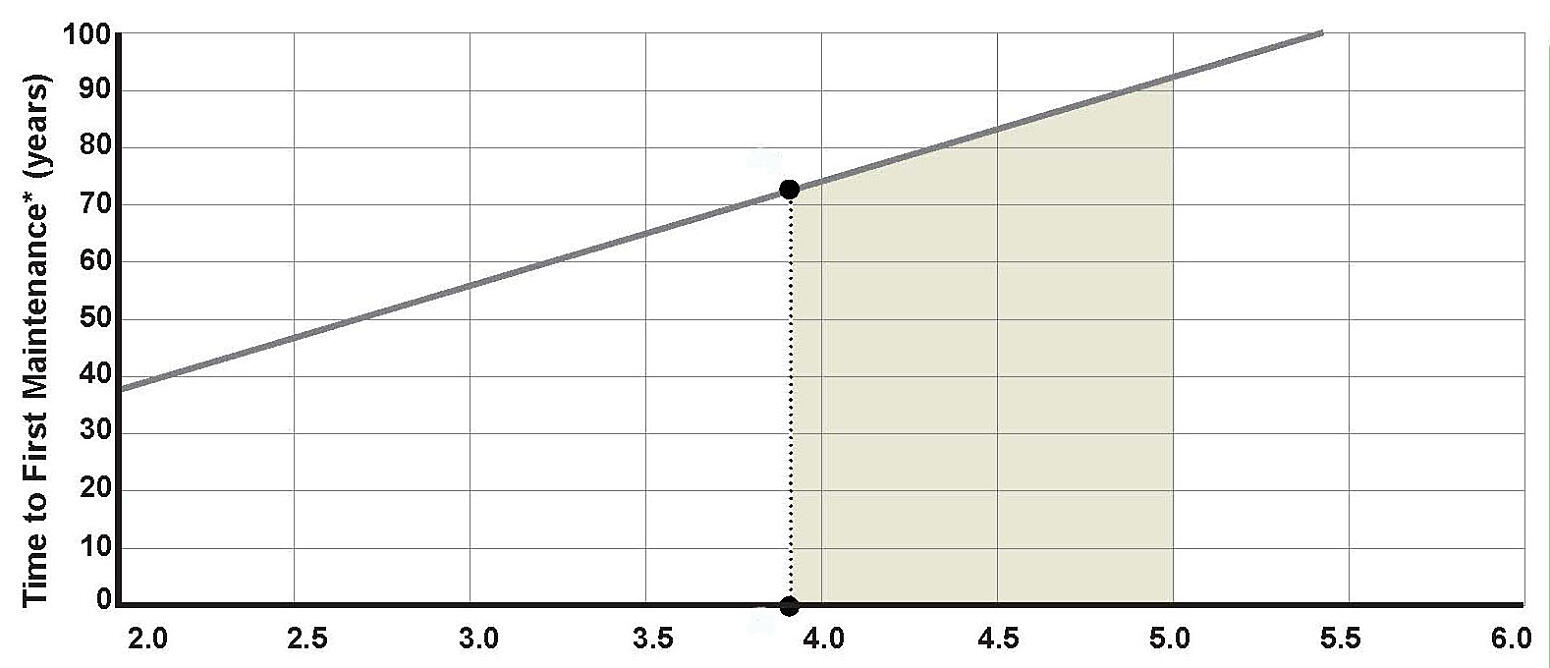

The chart below gives an example of an estimated time to first maintenance for large structural steel that has been hot-dip galvanized. The shaded area represents a typical coating thickness of 3.9 to 5.0 mils on the horizontal axis. For simplicity, only the plotline for an industrial climate is shown; all others have been removed. With this coating thickness range and this climate type, the vertical axis shows the coating will survive 70 to 90+ maintenance free years before requiring touch up or repair.

Background

The original version of the Time to First Maintenance Chart used average corrosion rates from real-world case studies to produce the plotted lines. The current version of the chart uses information from the Zinc Coating Life Predictor to approximate corrosion rates of zinc coatings in various environments. The Zinc Coating Life Predictor is an online tool primarily developed by Gregory Zhang and funded by the International Zinc Association. It uses real-world data in conjunction with laboratory results to produce an accurate zinc corrosion rate approximation.

In order to portray an accurate representation of an approximate time to first maintenance, the chart first divides corrosion rates into five climate types: rural, suburban, temperate marine, tropical marine, and industrial. Then using the Zinc Coating Life Predictor the corrosion rate of zinc is predicted in six separate locations within each climate type. Corrosion rates are generated by the online tool after environmental parameters for the given location are entered. The parameters include average rainfall, sulfur dioxide content, salinity, and average temperature. The corrosion rates from the six locations are then averaged together to produce the linear plot lines on the Time to First Maintenance Chart. The chart below gives the locations used to produce the data for each climate type.

Corrosion rates for zinc in atmospheric conditions are given in terms of coating lost per year. This could mean units of micrometers per year or mils per year. The linear plotlines on the Time to First Maintenance Chart reflect a consistent corrosion rate of the hot-dip galvanized coating against time.

© 2025 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.