How To Tell If Steel Has Been Galvanized

How can I tell if a piece of steel has been galvanized?

This question was actually received by one of the AGA staff and is a bit out of the ordinary. The question came from an Original Equipment Manufacturer(OEM) of trailers wanting to promote their trailers as using hot-dip galvanized steel in the construction. As it goes, the trailer manufacturer purchases some of the trailer parts from another company. The other company would not tell the trailer Original Equipment Manufacturer (OEM) if the parts were galvanized or not. (Call me suspicious at this point.) The caller indicated she was frustrated with not knowing and thought she could place a magnet on the manufactured part to determine if it was galvanized.

Strictly speaking, zinc is non-magnetic and of course, we use this principle when we measure zinc coating thickness. The tip of the pencil, banana, and electronic measuring device is magnetic and it is attracted to the substrate steel, which of course contains iron which is magnetic. Each gauge is calibrated to measure the space between the magnetic point of the gauge and the steel. However, the fact zinc is non-magnetic doesnt really help the caller out. Zinc can be applied in the form of dust (zinc-rich paint), hot-spray (metalizing), or powder (mechanical peening). Using a magnet or gauge will only determine if there is a zinc coating on top of the steel. And as a matter of fact, the gray coating she sees may be just paint. A film of paint would have a thickness to it.

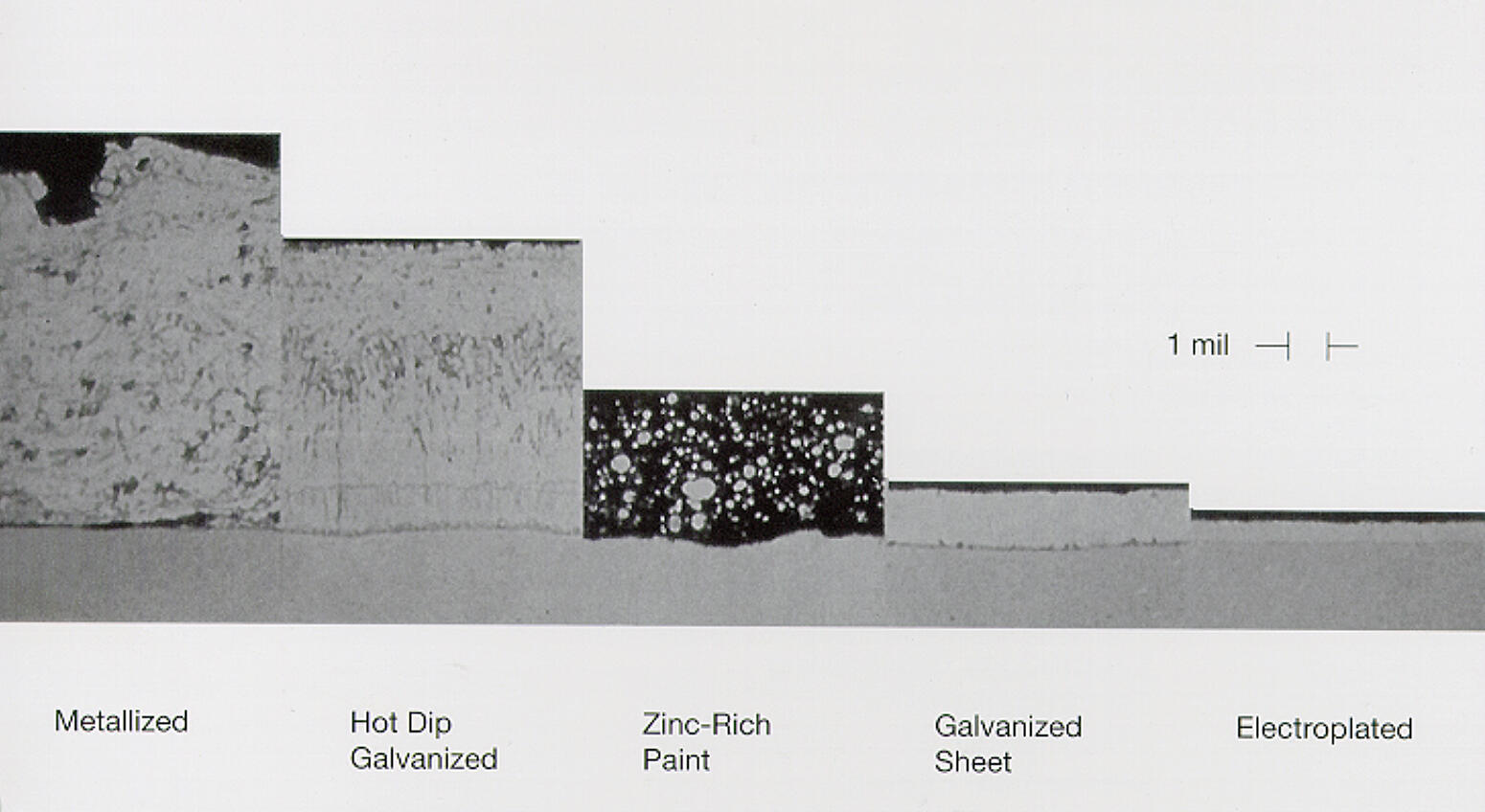

The only real way to determine if the coating is hot-dip galvanized would be to run laboratory testing. One test would be election paramagnetic resonance (EPR), or electron paramagnetic resonance. EPR shows the molecular content of material on an oscilloscope and galvanizing would show up as having high zinc content on the outer surface and zinc and iron content on the inner layers. Mechanical peening and metalizing would show no iron in the coating and zinc-rich paint would contain some binding material. Another method would be to take a cross-section of the coated steel and take a photomicrograph. Galvanizing would show the three intermetallic layers, metalizing and mechanical peening would indicate only pure zinc, and the zinc-rich paint would highlight the bonding material.

Because the three methods of zinc application are inferior to hot-dip galvanizing in terms of durability, hardness, consistency in coating thickness, etc., and the position of the parts company not to disclose the coating type, the advice of the AGA to the trailer manufacturer is to skip the expensive testing of these trailers parts and find a new supplier.

Coating Thickness Measurements

Magnetic coating thickness or electronic coating thickness gauges measure the thickness of a non-ferrous coating over a ferrous surface (steel). Zinc coatings, paints, and even zinc-rich paints are all successfully measured for thickness with this type of gauge when applied over steel. The tests are non-destructive and can be done in several spots over the surface of the steel. Hot-dip galvanizers and painters use coating thickness measurements to ensure conformance to specifications.

Owners often use this method to determine if the steel has been hot-dip galvanized. Its ease of use, availability, and non-destructive nature make it the first and obvious choice to confirm the presence of a coating. Before measurements are taken, the surface should be washed of all organic contaminants and loose particles that may interfere with coating thickness measurements. If a wide range of coating thickness measurements show non-zero readings, a non-ferrous coating is present on the steel.

While this method confirms the presence of a coating, it is unable to distinguish which non-ferrous coating is present. It may be a hot-dip galvanized coating, thermal spray (metallizing), mechanically plated, or even painted.

Once coating thickness measurements determine a non-ferrous coating is indeed present, visual clues can help decide what coating is being dealt with. For example, if blisters and chips are present, the coating used is most likely a paint. If the surface has a color other than hot-dip galvanizings natural matte gray appearance, it is also likely a paint. A paint over a galvanized coating may also be possible. If the surface posses the typical traits of a weathered hot-dip galvanized coating (matte gray, uniformly weathered, possible brown staining), it may be safe to infer that it is indeed a hot-dip galvanized coating.

Laboratory Testing

The only way to know for sure which coating is present is laboratory testing. Different forms of spectroscopy, for example, can take a sample of the coating in question and provide a breakdown of the materials present. A hot-dip galvanized coating may show a high zinc content near the outside of the coating with an increased iron content near the metal substrate. A zinc metallized or mechanically plated coating will contain a high zinc content through the entirety of the coating. A zinc-rich paint will also show a high zinc content, but will also contain other resins and binders typical to that system.

A photomicrograph of a cross-section of the coating may also be taken to determine which system has been used. A hot-dip galvanized coating will show the intermetallic layers indicative of a metallurgical bond. A metallized or mechanically plated coating will not have these layers. The figure below can be used to differentiate between these coatings.

Now that I know the steel is hot-dip galvanized, what do I do?

Leave It

Owners of weathered hot-dip galvanized steel have a few options moving forward. Leaving the steel as-is and relying on the present corrosion protection may be a viable option. A fully weathered hot-dip galvanized coating will not have the bright and shiny appearance of a new coating, but if an adequate amount of zinc is still present on the steel, an older coating will provide several more years of corrosion protection. The previously taken coating thickness measurements and the AGAs Time to First Maintenance chart can be used to predict the remaining corrosion protection performance.

Paint / Repair It

The owner may also decide to topcoat a weathered galvanized coating with a paint system. Painting over galvanizing is often referred to as a duplex system. The paint will provide several added benefits to a galvanized coating including extra corrosion protection and a new aesthetic appeal. Painting a fully-weathered hot-dip galvanized coating is often done successfully with little surface preparation required. The naturally occurring zinc patina forms an adherent profile on the surface of the coating that is excellent for paint systems. According to ASTM D6386 Standard Practice for Preparation of Zinc (Hot-Dip Galvanized) Coated Iron and Steel Product and Hardware Surfaces for Painting, surface preparation of a fully-weathered galvanized coating is simple and includes an inexpensive power-wash.

Repairing bare or damaged areas of the hot-dip galvanized coating is also an option if the owner does not wish to repair the entire surface. ASTM A780 Standard Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings gives the options of zinc-rich paint, zinc metallized spray, or zinc-based solders as acceptable repair materials. This may be an option if there are only minor signs of rusting and few areas in need of repair.

Re-Galvanize It

If the galvanized coating has degraded too far, and more corrosion protection is needed, there is the option of removing the old galvanized coating and replacing it with a new one. Fortunately, the chemical cleaning process used by hot-dip galvanizers is also capable of removing a zinc coating from the surface of the steel. Some galvanizers even have a separate acid bath used specifically for this purpose. Steel that has been galvanized in the past can be sent to a galvanizing facility, removed of the old coating, and be re-coated all in-house. Recycling steel in this sustainable manner saves the owner time and money.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.