HDG and Fuel Storage Tanks

Can Hot-Dip Galvanizing be used to protect gasoline and diesel fuel storage tanks?

Corrosion protection of a steel fuel storage tank not only involves the protection of the outside of the tank to atmospheric corrosion but the corrosion protection from fuel being stored in the tank.

The concern is small particulates that may form in the diesel fuel due to the interaction between the zinc and fuel occurring within the tank. These particulates may end up clogging injectors or filters when the stored fuel is used in diesel engines. However, this problem does not seem to be too alarming and is only noticeable with smaller tanks. When large tanks typical of what is used in practice are used, the clogging problem becomes negligible. This is due to the weight of the particulates. Heavier than the fuel, they tend to rest undisturbed near the bottom of the tank. Regular cleaning of an in-line fuel filter may also be an option if the clogging problem seems to persist.

A hot-dip galvanized coating has also been found to be very useful in protecting steel from corrosion with gasoline. When exposed to long-term immersion or vapors, zinc shows little signs of corrosion and is very useful in this application. An exception: in hydrated fuels or fuels with water contamination, corrosion of the zinc will be rapid.

If this is the case, voluminous corrosion products will form and create problems when used in some fuel systems. There have also been reports of problems when fuel additions based on ethanol are used with gasoline. For this reason, galvanized steel works best with a duplex system when it is used for the storage of gasoline.

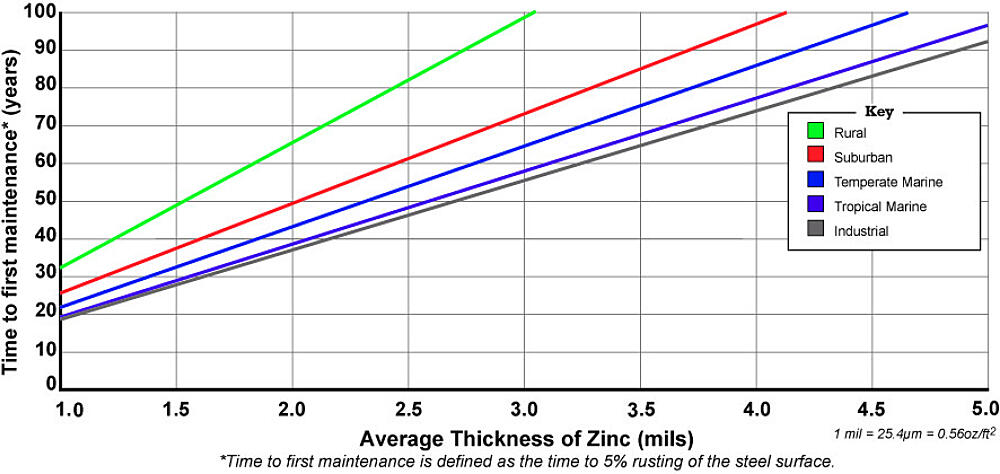

The exterior of a large storage tank will be protected by hot-dip galvanizing the same as any other atmospherically exposed galvanized steel. The corrosion rates will be predictable based on the environment of exposure and service life will span several decades. As with all hot-dip galvanized steel exposed to the atmosphere, the coating's time to first maintenance on the exterior of the storage tank can be estimated using the Time to First Maintenance Chart.

Hot-dip galvanized steel can be used to protect storage tanks against corrosion from gasoline, oil, and diesel. The concerns arise from zinc corrosion products that cause particulates to accumulate in the bottom of the fuel tank. These particulates may cause clogging problems in fuel systems, but are usually not a problem if the storage tank is large enough or if the fuel is properly filtered. As always, the exterior of the tank will benefit from the superior atmospheric corrosion protection of a hot-dip galvanized coating.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.