Galvanizing Abrasion Resistant Steel

I galvanized an abrasion resistant steel, but the tensile strength was below the recommended 150 ksi. The steel became very brittle after the process. What happened?

Abrasion resistant steel, sometimes referred to as tool steel, is used in a variety of industrial applications. Designers choose it for tools as small as a hammer, to ones as large as the business end of a front-end loader or the bed of a dump truck. Most abrasion resistant steels have a high tensile strength and hardness rating. It is the high hardness rating that allows the steel to be wear resistant and used in applications calling for excessive wear and tear. Galvanizers usually have an easy time avoiding abrasion resistant steel, as the tensile strength will be well over the recommended 150 ksi in ASTM A385. Steel like this cannot be hot-dip galvanized without modifying the galvanizing process, or running the risk of embrittlement.

However, there are abrasion resistant steels with a relatively low tensile strength. Heat treatments harden a steel, causing it to become abrasion resistant without the tensile strength being too high to galvanize.

Steels like these pose potential problems to galvanizers as they may seem acceptable to hot-dip galvanize, but will become very brittle upon completion of the galvanizing process. The heat treatment the steel has already received, coupled with the thermal cycling in the zinc bath, will cause an excessive amount of strain-age embrittlement. In some cases, the steel has been reported to shatter like glass when being handled within the facility.

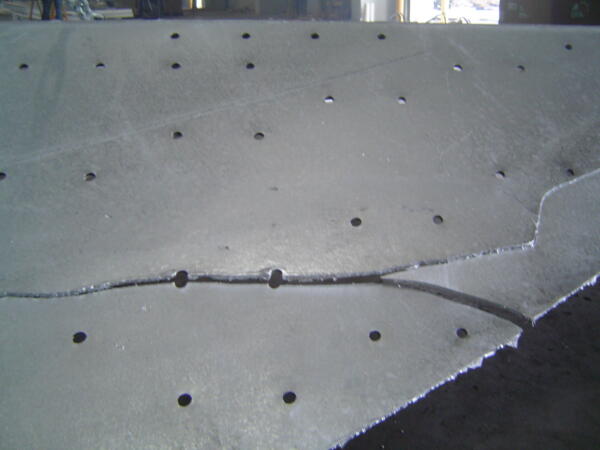

The pictures shown here are examples of abrasion resistant steel becoming very brittle after the galvanizing process. The received steel may have met all the chemical and mechanical recommendations tensile strength below 150 ksi, correct silicon content, etc. but was clearly not suitable for galvanizing. This is due to the hardness of the steel and from the thermal treatments it received.

So the short answer to the question: When asked to galvanize an abrasion resistant steel, walk away! Even if everything else looks right, the term abrasion resistant is a huge red flag to a galvanizer.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.