Corrosion Rate of Galvanized Steel

Can I assume the corrosion rate of a galvanized coating will be the same in all similar environments? For example, will the corrosion rate in Arizona be the same as it would be in Abu Dhabi?

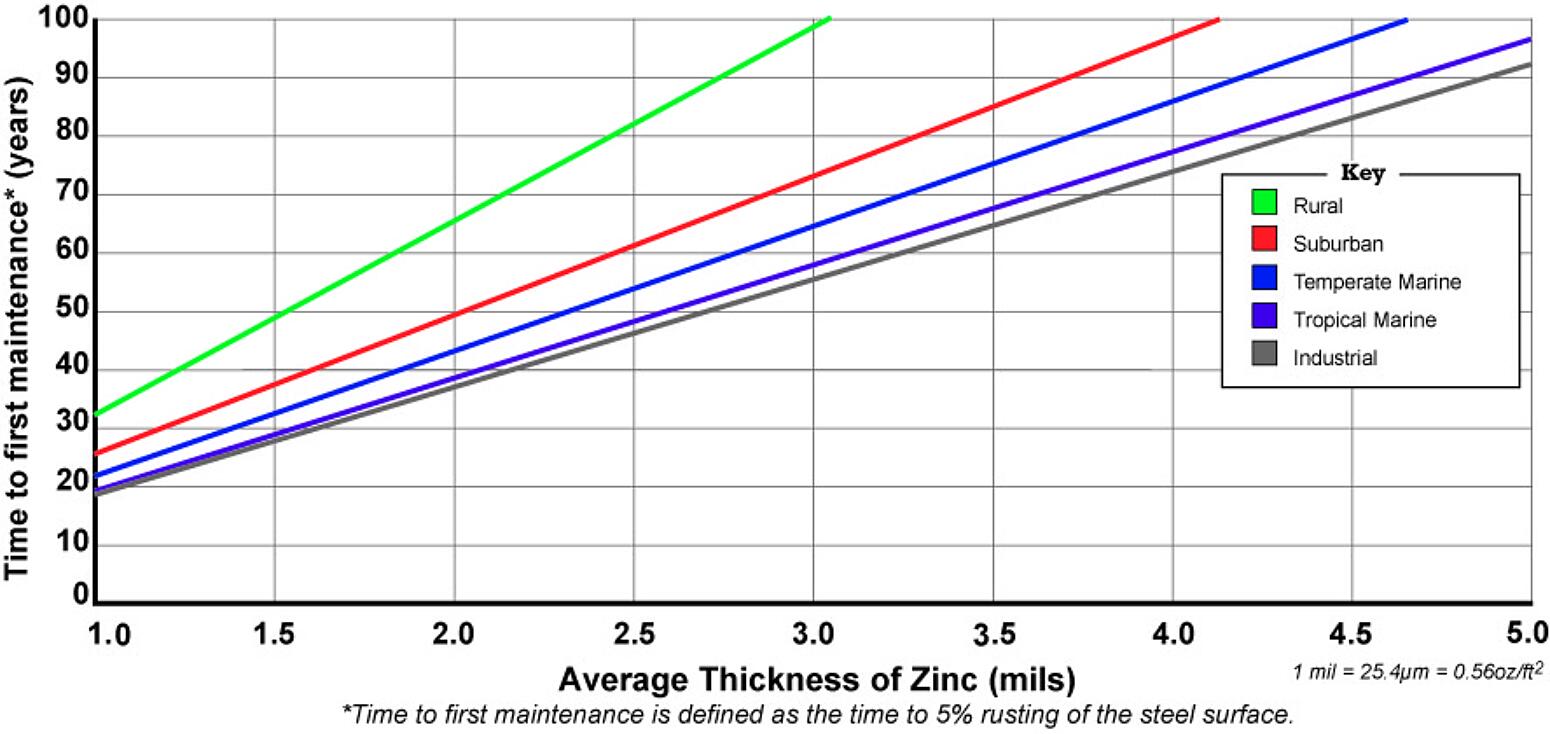

In most cases, the corrosion rate experienced by a hot-dip galvanized coating in one specific location will be a good indicator of how the coating will behave in a similar environment. This fact is demonstrated by the AGAs Time to First Maintenance chart which averaged the corrosion rate experienced in five environmentally similar locations to produce one accurate estimation for that type of environment. So to answer the question, Will the corrosion rate be the same in a similar environment? The answer is usually, Yes!

However, corrosion is a complex subject and questions like this are answered with the rather ambiguous it depends. Unfortunately, this question must be answered in the same frustrating manner. There may be an environment presenting itself as similar to one you are familiar with, leading you to believe you can easily and accurately predict the corrosion rate galvanized steel will face in that region. But there may be one subtle difference between the two that can drastically change corrosion rates and leave you surprised when the corrosion protection performance of the galvanized coating isnt what was predicted; It depends.

For an example of the it depends phenomenon, examine the cities of Los Angeles, California and Abu Dhabi, United Arab Emirates. Both environments would be considered coastal and industrial. The rainfall in Los Angeles is higher than in Abu Dhabi, but a lower temperature suggests the corrosion rates should be similar. If using the Time to First Maintenance chart, one would use the industrial corrosion rate to predict the performance of galvanized steel in both areas. But the real world data shows something quite different.

Corrosion rates of galvanized coatings in Los Angeles average 1.6 micrometers per year. In Abu Dhabi, the observed corrosion rate is more than double this, with some reports being higher than 5 micrometers per year! What could possibly be so different about these two industrial cities in coastal environments that could create such a stark contrast between the corrosiveness of their respective environments? In this case, the it depends answer points to higher airborne salinity levels in Abu Dhabi and rapid shifts in relative humidity in the area. The shifts in relative humidity lead to an almost daily deposit of dew (with high salinity levels) on exposed surfaces. This leaves a corrosive layer of brine on the galvanized surface that will be washed away and re-deposited almost every day.

While the environments of Los Angeles and Abu Dhabi may be similar, a subtle difference between the two caused a deceptively corrosive environment in Abu Dhabi. The lesson here is the behavior of galvanized steel in any particular environment cannot be assumed. The Time to First Maintenance chart provides a quick visual representation of atmospheric corrosion data, but it would also be helpful to find more information on the location in question. The Zinc Coating Life Predictor is a great tool for this as well as information from people with experience in a said area.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.