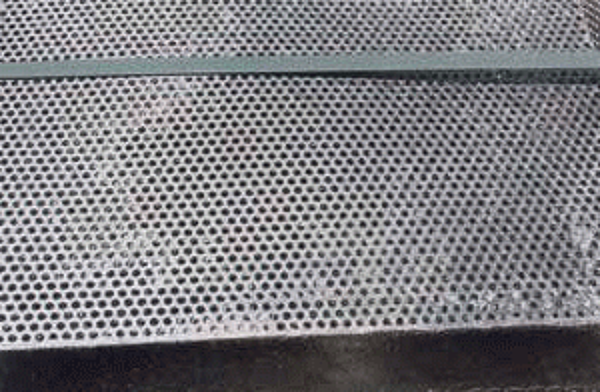

Clogged Holes During Galvanizing

Whose responsibility is it to clear holes clogged during galvanizing?

ASTM A123/A123M discusses clogged holes in Section 6.4 Appearance and states:

- Plain holes of ½ inches diameter or more shall be clean and reasonably free from excess zinc.

The galvanizer is responsible for ensuring holes ½ inch in diameter do not have excess zinc, such as clogged holes or other heavy deposits of zinc that would interfere with the intended use of the product. Be sure to inspect holes before delivery to the customer. For holes under a ½ inch in diameter, the galvanizer is not responsible for clearing clogged holes. In those instances, the fabricator or other galvanizing customer is responsible for clearing clogged holes.

Clogged holes can be cleaned by heating the area of the hole and using a metal bristle brush to clear out the excess zinc. There are two ways to decrease the chances for zinc clogging holes during galvanizing. Zinc chemistry plays a role in reducing surface tension. Lead and bismuth, and to a lesser extent aluminum reduce the surface tension of zinc and help it to flow more easily off the steel as the part is being removed from the galvanizing kettle. One way the galvanizer has control over zinc flow from the steel is how the piece is oriented when hung for dipping. Hanging the steel (and removing it from the kettle) in a more vertical manner will help the zinc to flow down and away from holes. When steel is hung horizontally (or removed from the kettle horizontally), the zinc tends to gather at holes rather than flow away from them.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.