Chemical Reaction between Chromates and Galvanized Steel

I have a customer who wants to understand the chemical reaction between the galvanized steel and the chromate passivation treatment and why they should request chromate treatment. What is the chemical reaction of this process? What are some of the advantages of using a chromate treatment for galvanized reinforcing steel?

The passivation of the zinc surface is often done by chromating the galvanized steel. The high corrosion resistance offered by the use of chromate films is attributed to the presence of hexavalent and trivalent chromium in the coating. The trivalent chromium is believed to be present as an insoluble hydrated oxide (chromium hydroxide or zinc chromate), whereas the soluble portion of hexavalent chromium imparts a "self-healing" character to the film during the oxidative (corrosive) attack by species, such as chloride ions.

The chromate film on the galvanized reinforcing steel is formed by the chemical reactions of hexavalent chromium with a metal surface in the presence of other components, or "activators" in acid solution. Hexavalent chromium is partially reduced to trivalent chromium during the reaction, with a concurrent rise in pH, forming a complex mixture consisting largely of hydrated basic chromium chromate (Cr203 Cr03 x H20) and hydrous oxides of both chromium and the basis metal (zinc). As the acid is consumed, the combining power of chromium in the solution changes and precipitates chromium hydroxide. A film builds until the face next to the zinc becomes nonacid and this stops the reaction. The resulting gel-like film is allowed to harden. Chromate coatings on galvanized steel are usually yellow and consist of a mixture of trivalent and hexavalent chrome solution. The chemical reaction of the chromate to the galvanized steel is shown below:

- Reduction of hexavalent chromium to trivalent chromium 3Zn + 2Cr+6 ------> 3Zn+ 2Cr+3

- Dissolution of metal by acid (hydrogen loss) accompanied by a local rise in pH at the metal interface Zn + 2H------->Zn + H2 (gas)

A redox reaction occurs at acidic pH where hexavalent chromium is reduced to trivalent chromium while zinc is oxidized.

- Zn ------>Zn2+2e

- HCrO4+14H+6e ------> 2Cr2+7H2O

The primary reason for the use of chromate treatments on the galvanized steel parts is to prevent the formation of wet storage stain during the first six weeks after galvanizing. The zinc coating is most vulnerable to the formation of excessive amounts of zinc oxide and zinc hydroxide during this period. The thin layer of chromate passivation layer inhibits the formation of these zinc oxides. The coating generally lasts about six weeks before it is consumed. Galvanized steel will then weather naturally after the chromate is gone.

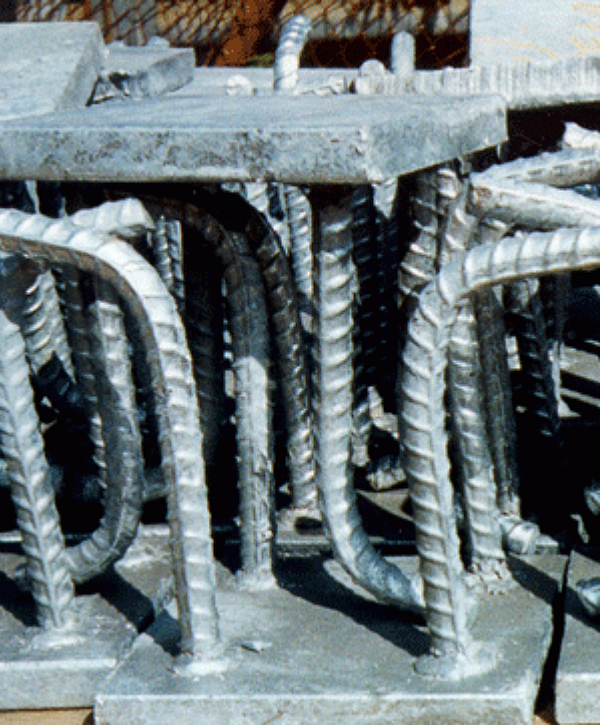

Chromate passivation treatments are used to control reactions between the zinc and the concrete. The main reaction that chromate treatment prevents is the hydrogen evolution that may affect the bonding properties between the zinc and concrete. Zinc is amphoteric (reactive in acidic and alkaline environments) so the maximum rate of attack on zinc occurs in alkaline conditions over a pH of 12.5. The passivation of zinc is effected in the pH range of 8 to 12.5, due to the initial formation of a layer of zinc hydroxide and subsequently of a complex calcium zinc compound, calcium hydroxy-zincate (Ca[Zn(OHbl 2H20)]. The reaction of zinc with the concrete effectively ceases in a few days and gives just sufficient corrosion products to ensure a strong and reliable bond to the concrete when fully hardened. The bonding between galvanized rebar and concrete is essential for the reliable performance of concrete structures. Many factors, such as concrete mix and additives, curing conditions, and age, may affect the bonding between the galvanized steel and concrete. The chemical reaction that is of concern is the reaction of zinc with calcium hydroxide.

This reaction occurs during the curing of the concrete. During the curing process, hydrogen gas evolution occurs between the galvanized rebar and the concrete. The use of a passivation treatment, such as the use of chromates, can help to reduce the hydrogen gas from forming. In solutions with such a high pH, the zinc is attacked by the alkalis (calcium hydroxide) in the fresh concrete, leading to the formation of calcium hydrozincite and hydrogen. This reaction could give rise to poor adhesion. Once the concrete sets, the hydrogen evolution ceases; the coating of calcium zincate formed apparently provides a protection to the reinforcement and no further attack takes places after initial setting. Tests of the bond strength on galvanized rebars showed equal to or slightly better bond performance when compared to black rebars.

© 2026 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes all liability arising from such use.