Finish: Surface Conditions

When inspecting the finish of the hot-dip galvanized coating, a variety of surface conditions can be observed. Several factors can affect the finish of the galvanized coating - some of these factors can be controlled by the galvanizer while others cannot. The specification requirement for finish is the coating must be smooth, uniform, and continuous. There are many subjective interpretations for what that means; however, the key to whether surface conditions are acceptable or not relates to its effect on the long-term corrosion performance. If the surface condition will not lessen the long-term corrosion resistance of the piece, it is acceptable. On the other hand, if the condition compromises the life of the coating, it is cause for rejection.

If a hot-dip galvanized steel part has been rejected for any reason other than embrittlement, the part may be repaired and/or regalvanized and resubmitted for inspection. There are specific limitations to repairable areas, which will be discussed later in this publication. If the area does not meet the requirements for repair, the part can be stripped and regalvanized and then inspected again. It is important to note galvanizing does not change the mechanical properties of the steel, so there is no additional issue/concern with stripping and regalvanizing the part.

The following is a list of surface conditions that can be present after galvanizing. The next sections will review each of these conditions, their cause, and whether they are acceptable according to the specifications.

A - C

- Bare Spots

- Blasting Damage

- Chain and Wire Marks

- Clogged Holes

- Clogged Threads

D - E

- Delamination

- Distortion

- Drainage Spikes

- Dross Inclusions

- Excess Aluminum in Galvanizing Bath

F - O

- Fish Boning

- Flaking

- Flux Inclusions

- Grinder Marks

- Oxide Lines

P - R

- Products in Contact

- Rough Surface Condition

- Runs

- Rust Bleeding

S - T

- Sand Embedded in Casting

- Skimmings

- Striations

- Steel Surface Condition

- Surface Contaminant

- Touch Marks

U - Z

- Weeping Weld

- Welding Blowouts

- Welding Spatter

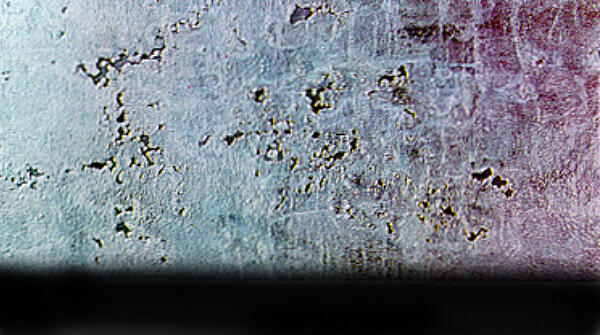

- Wet Storage Stain

- Zinc Skimmings

- Zinc Splatter