In the Atmosphere

Every transportation project is exposed to the atmosphere. The performance of atmospherically exposed hot-dip galvanized steel depends on five main factors: temperature, humidity, rainfall, sulfur dioxide (pollution) concentration in the air, and air salinity. None of these factors can be singled out as the main contributor to zinc corrosion, but they all play a role in determining the corrosion protection hot-dip galvanized (zinc) coatings can provide in certain atmospheric conditions.

For several decades, independent and industry testing of samples in five environments (industrial, rural, suburban, tropical marine, and temperate marine) have yielded real-world performance data for hot-dip galvanized steel. Using this real-world corrosion data, statistical methods, and neural network technology, Dr. Gregory Zhang of Teck Metals Ltd. developed the Zinc Coating Life Predictor (ZCLP) to estimate the life of hot-dip galvanized coatings in atmospheric conditions. Using the ZCLP, you can input specific parameters for any environment and get an estimated time to first maintenance for the galvanized coating.

Time to First Maintenance

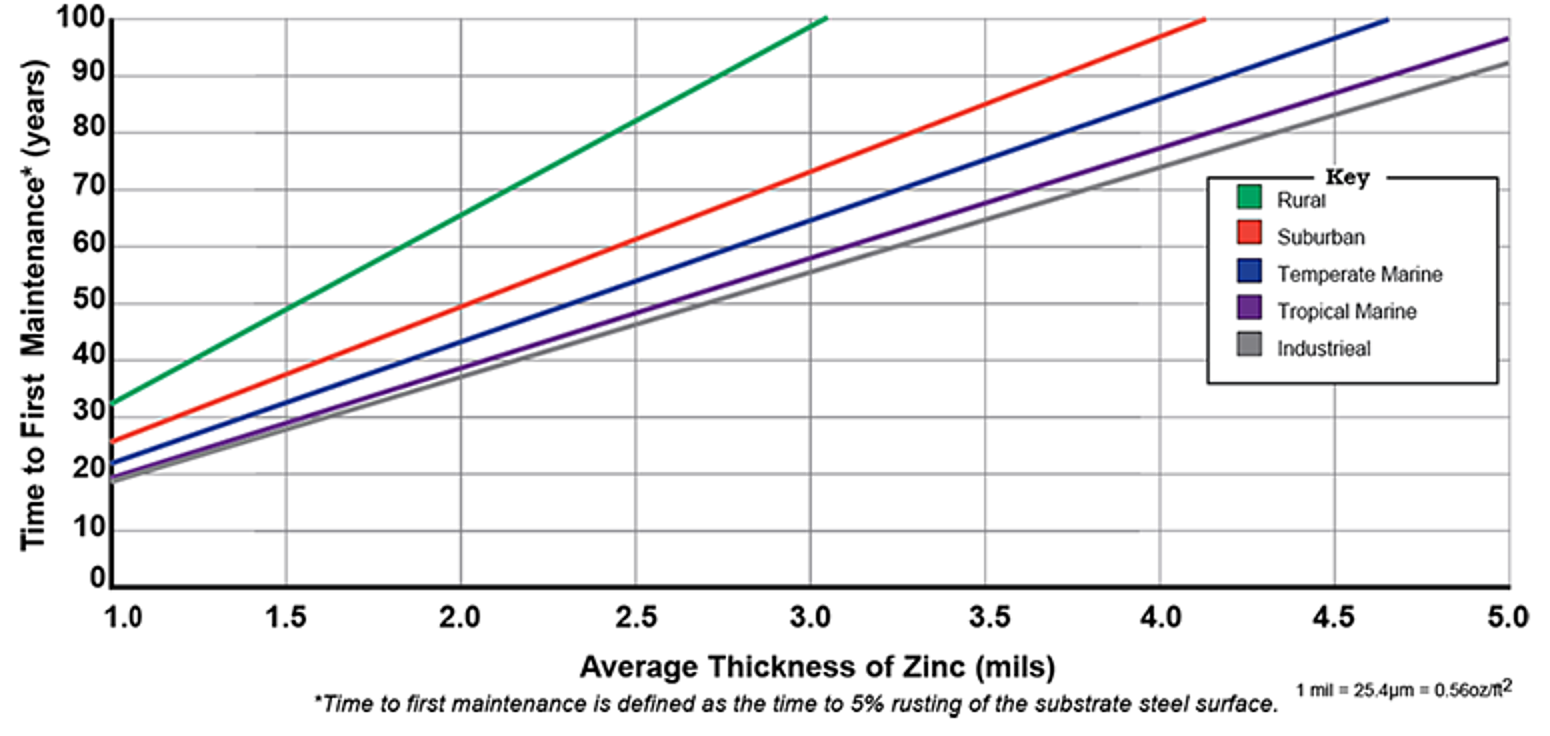

Because hot-dip galvanized steel is most commonly exposed to the atmosphere, the AGA developed the Time to First Maintenance chart to help predict HDG's performance in the atmosphere. The chart was developed by selecting five to six locations in each atmospheric category and plotting the predicted life to get an estimated time to first maintenance for each environment (industrial, suburban, etc.)

Time to first maintenance is defined as 5% rusting of the base steel surface, which means 95% of the coating is still intact, and an initial maintenance is recommended to extend the life of the structure. According to ASTM A 123, the governing specification for hot-dip galvanizing, steel ¼-inch thick or greater must have at least 3.9 mils of zinc on the surface, but more often than not, you will get greater than the minimum requirement. Therefore, using this chart, you can see hot-dip galvanized structural steel (>1/4-inch thick) provides 72-73 years of life to first maintenance even in the most corrosive atmosphere, industrial.

As public pressure and federal funding are moving towards a goal of 100-year bridges, avoiding the monumental costs associated with partial or complete shutdown of a bridge for maintenance is a key element when specifying a corrosion protection system. Additionally, many airfield elements, highway products, and items throughout mass transit lines are constantly exposed to the atmosphere and their uninterrupted service is critical to efficiently transport passengers.