Hot-Dip Galvanizing (HDG) Process

Now that you have a better understanding of the current state of the power industry and the unique corrosion challenges throughout the grid, lets discuss hot-dip galvanizing (HDG) and how it can be used effectively in power infrastructure.

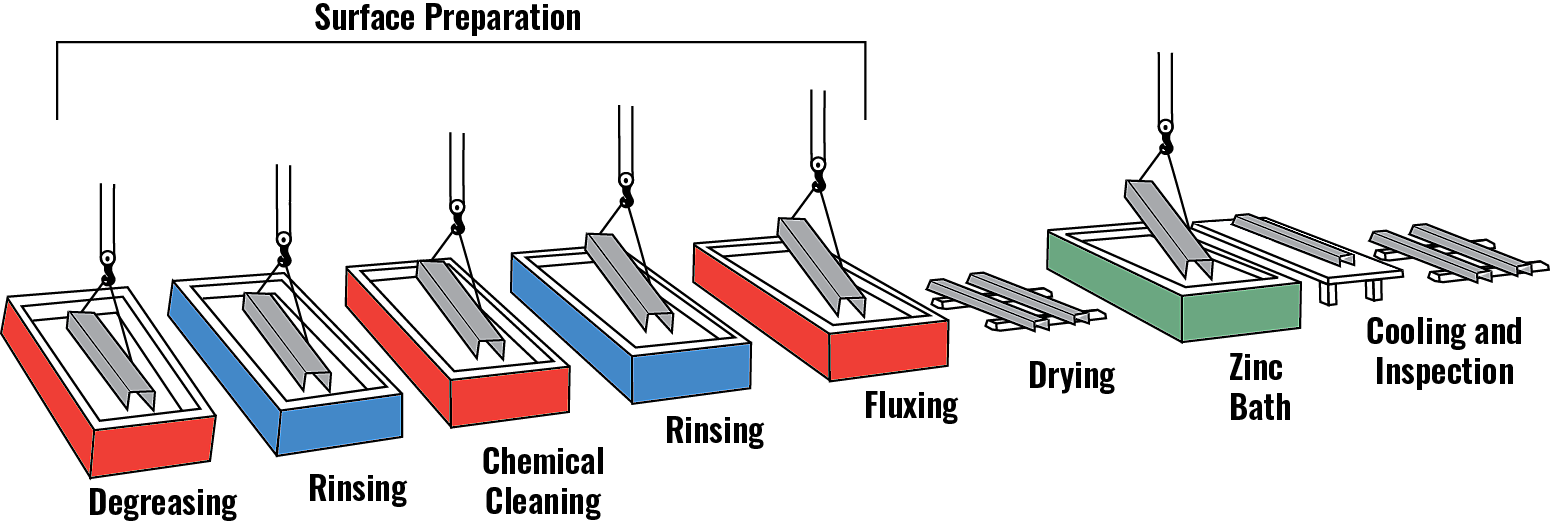

Hot-dip galvanizing is the process of coating fabricated steel by immersing it in a bath of molten zinc. There are three fundamental steps in the galvanizing process: surface preparation, galvanizing, and inspection. Lets review each in more detail.

Surface Preparation

When the fabricated steel arrives at the galvanizing facility, it is hung by wire or placed in a racking system which can be lifted and moved through the process by overhead cranes. The steel then goes through a series of three cleaning steps; degreasing, chemical cleaning, and fluxing. Degreasing removes dirt, oil, and organic residues, while the acidic chemical cleaning bath will remove mill scale and iron oxide. The final surface preparation step, fluxing, will remove any remaining oxides and coat the steel with a protective layer to prevent any further oxide formation prior to galvanizing. Proper surface preparation is critical, as zinc will not react with unclean steel.

Galvanizing

After surface preparation, the steel is dipped in the molten (830 F) bath of at least 98% zinc. The steel is lowered into the kettle at an angle that allows air to escape from tubular shapes or other pockets, and the zinc to flow into, over, and through the entire piece. While immersed in the kettle, the iron in the steel metallurgically reacts with the zinc to form a series of zinc-iron intermetallic layers and an outer layer of pure zinc.

Inspection

The final step is an inspection of the coating. A very accurate determination of the quality of the coating can be achieved by a visual inspection, as zinc does not react with unclean steel, which would leave an uncoated area on the part. Additionally, a magnetic thickness gauge can be used to verify the coating thickness complies with specification requirements.

For more detail about the galvanizing process, the 1-hour Core Galvanize It! Seminar explains this process in detail as well as ASTM specifications referring to galvanizing, and helpful hints about fabrication before galvanizing.