Life-Cycle Assessment (LCA)

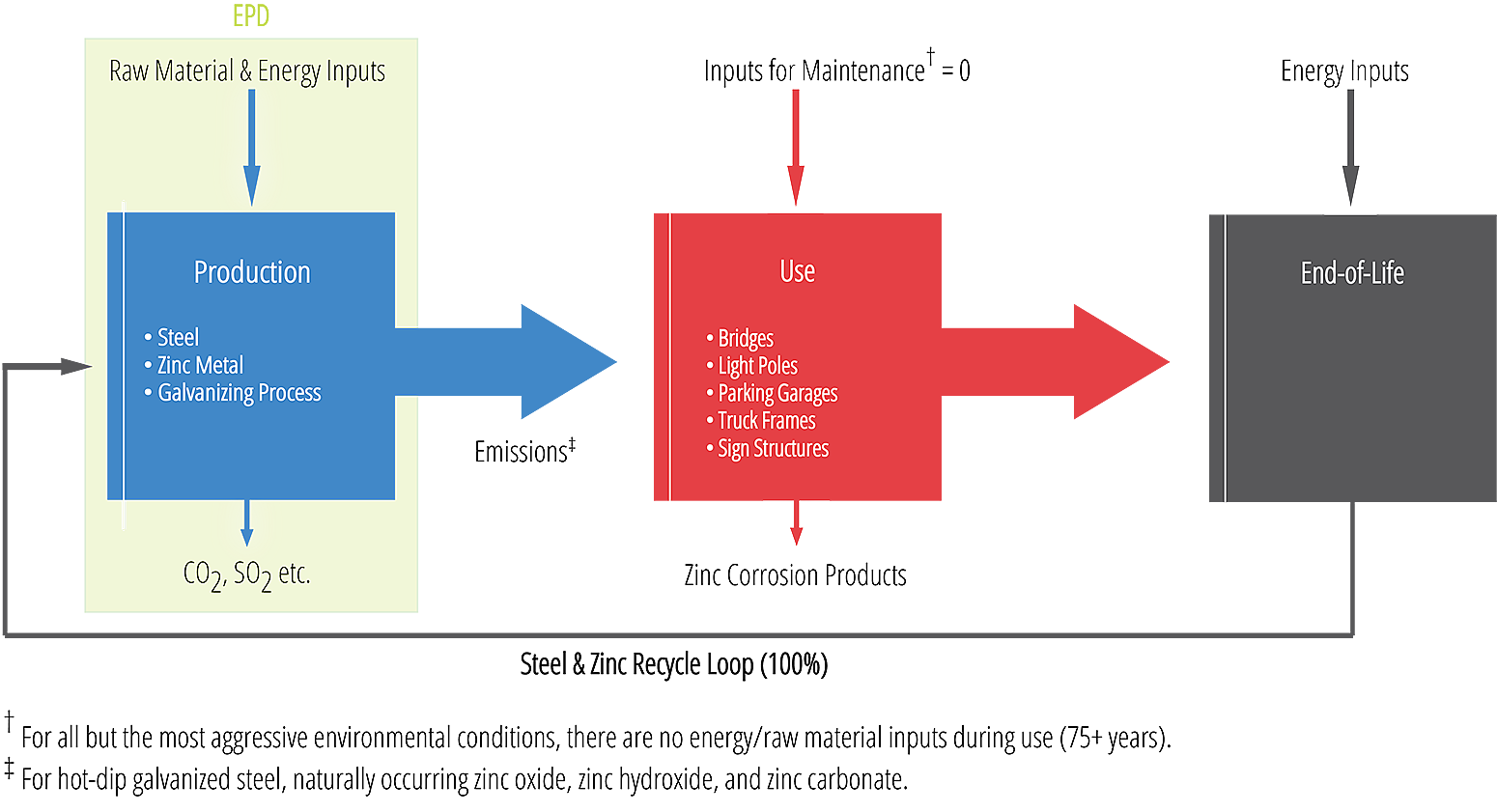

Life-cycle assessment measures all input and output from a system related to the production, use and end-of-life of a product. Because there may be many components of a product and several processes, each must first be measured in what is known as a life-cycle inventory (LCI) study. For hot-dip galvanizing, an individual LCI was conducted for zinc, steel, and the galvanizing process. LCI are often referred to as a gate to gate study. The sum of the three LCI is equal to all of the energy and raw material input for just the production phase of galvanized steel.

The emissions associated with each LCI is the total environmental impact (emissions) during this phase and is measured in three key criteria, global warming potential (GWP), acidification potential (AP), and photochemical ozone creation potential (POCP). This measurement of energy and emissions from raw material production all the way through to when the product is ready for use is often referred to as the cradle to gate study.

In an LCA, any energy, labor, and materials required to maintain the product during the use phase, as well as emissions are identified. As the diagram indicates for HDG, there is no environmental cost associated with HDG. No maintenance is required. This is the strength of HDG compared to paints and concrete. And finally, LCA measures the environmental impact of the recycling/waste phase, called end-of-life. For HDG, there is actually a credit to the overall primary energy demand because using recycled zinc and steel requires less energy than would be required for mined zinc and virgin steel made from ore, coke, and iron. Painted steel also receives a credit for end-of-life but it is a result of the steel component and not the paint. The paint itself becomes a permanent part of the waste stream.

LCA tallies all of the raw material and energy required in the production, use, and end-of-life phases, applying any credit for recycling, and measuring environmental impact in three key criteria, CO2 output, AP, and POCP. LCA is also known as a cradle-to-grave study, or more appropriately for HDG a cradle-to-cradle study, as it is 100% recycled.

LCA differs from LEED because LEED only focuses on the recycled content of the product in production, and environmental impact during use, where as LCA examines the inputs and outputs from cradle-to-grave.

Life Cycle Analysis Study

A detailed life cycle assessment conducted by the Steel Market Development Institute (SMDI), a business unit of the American Iron and Steel Institute, in 2013 found that when comparing overall environmental performance, galvanized steel utility poles outperform wood poles in key environmental measures.

The study compared the use of galvanized steel and wood utility poles in the southeastern United States over a 40-year time horizon. It stands apart from previous studies in that it applied advanced LCA methods to ensure a more comprehensive assessment and reporting of the full range of potential environmental impacts associated with both galvanized steel and wood, including local and regional ecological impacts.

Among its findings, the study showed that replacing wood utility poles with galvanized steel will likely result in lower levels of greenhouse gas and aerosol emissions associated with global climate change, a lower burden on critical energy resources, reduced impacts on the habitats of many threatened and endangered species, and reduced impacts associated with hazardous emissions and wastes. The primary drivers for these findings are the longer lifespan of steel poles, high steel recycling rates, and the overall ecological and land use impacts of growing, harvesting and replanting the forests used to produce wood poles. For more information on this report please visit the Steel Utility Pole Coalition's website page that summarizes this report.