Sustainability

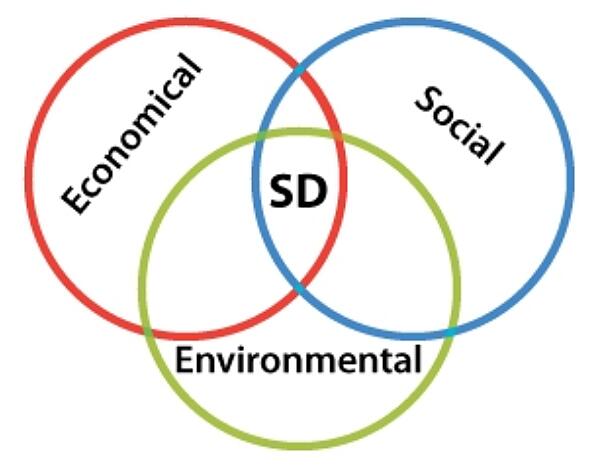

Sustainable development is the social, economic, and environmental commitment to growth and development that meet the needs of the present without compromising the ability of future generations to meet their own needs. As the social pressure continues to mount to construct the built environment sustainably, specifiers are becoming more invested and analytical in the materials they choose. Hot-dip galvanized steels maintenance-free longevity provides positive environmental and economic benefits to future generations.

Environmental Advantages

A significant aspect of striving for a more sustainable built environment is to evaluate the materials used in construction. In particular, it is important to evaluate the content and availability of the raw materials as well as the impact of processing them.

When it comes to hot-dip galvanizing, it’s important to remember the primary components (zinc and steel/iron ore) are both natural elements (4th (iron) and 24th (zinc) in order of abundance) which means we are not introducing harmful, man-made elements into the environment. In fact, both iron and zinc are essential to life and healthy reproduction.

Adding to the natural abundance and necessity to life, both zinc and steel are 100% recyclable without the loss of any chemical or physical properties. This means they can be multi-cycled (used as zinc/steel over and over again) rather than down-cycled into a lesser product – making hot-dip galvanized steel a truly infinitely renewable resource. Furthermore, both steel and zinc have high reclamation rates, which means recycling them is not merely a talking point, it is done as a common practice. Approximately 80% of zinc available for recycling is reclaimed, and for steel, the most recycled material in the world, it is nearly 100% (98%+).

Finally, the maintenance-free longevity provided by galvanized steel significantly reduces or eliminates the need of more natural resources and output of emissions throughout its service life.

The AGA has produced an industry-wide, 3rd party verified Environmental Product Declaration (EPD) in accordance with the LEED v4 standard. The EPD covers hot-rolled sections, plate, and hollow structural sections (HSS). The study was conducted by thinkstep, Inc. and verified by UL Environment, and can be found on our website at www.galvaniziet.org/epd.

Rivier Cochon Gras Bridge

Perches, Haiti- 2019

There’s an old saying, “one person’s trash is another person’s treasure.” In the case of the Riviere Cochon Gras Bridge, that saying became reality. An 80-foot section of the temporary Fore River Bridge which carried people over the river between North Weymouth and Quincy Point, Massachusetts for 15 years, was reused to help the community of Perches, Haiti.

Perches is a remote community in Haiti near the Riviere Cochon Gras. The river crossing was prone to regular flooding and there was no bridge in place. When the river flooded, residents were restricted from medical care and local services, and there had even been a few cases of drownings over the year as people attempted to cross the river to get into town.

With this re-purposed structure now in place, the bridge will provide residents greater access to other parts of their country and help to improve the daily lives of everyone in the community.

In its previous life, this bridge made up part of the massive temporary bridge on Route 3A connecting the city of Boston with the vacation/recreational area of Cape Cod. When the original Fore River Bridge was designed and built by Acrow Corporation, the company knew they had to build a temporary bridge that would be maintenance free for at least fifteen years. The company and the bridge owners got much more than they expected. The bridge handled about 46,000 total vehicles per day with a high percentage of heavy trucks at around 20% or 9,000 per day. Fifteen years of high traffic demand, harsh New England winters, salt and deicing chemicals were no match for the hot-dip galvanized coating on the structure.

Once the temporary bridge was taken down, the new bridge owner, the Cashman Family Foundation, knew there was much more life left in it and others who could benefit from the structure. Their idea was to reuse sections of the bridge to help third world countries connect people with local infrastructure, without the risk of crossing flooded waters. In Perches, an unpaved road with no crossing was the only way to access a local hospital and an industrial park to the North. During the three of four rainy months, the crossing is frequently impassable. The reused bridge section would literally be a lifesaver for the residents in the community.