Dissimilar Metals

Where zinc comes into contact with another metals, the potential for corrosion through a bi-metallic couple exists. The creation of a bi-metallic couple will lead to accelerated corrosion to the anodic metal. The extent of the accelerated corrosion is dependent on the positions of the metals in the galvanic series as well as the relative size of the surface area of the two metals in contact.

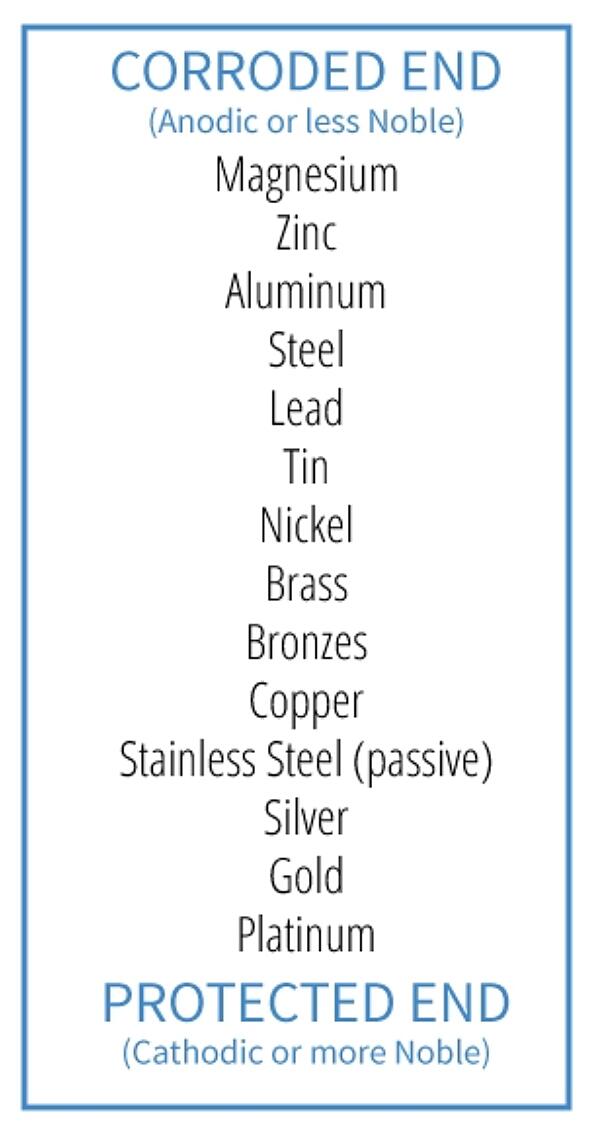

Zinc, which comprises the hot-dip galvanized coating is very high on the Galvanic Series (right), which means it will be anodic to most other metals. So, when hot-dip galvanizing is connected to other metals, the zinc coating will not only sacrifice itself to protect the underlying base steel, but also try to protect the other connected metals. This will lead to a more rapid consumption of the zinc coating, and decrease the overall life.

When it comes to bridge design, the most common other metals that may come in contact with the steel are likely painted (bare) steel, weathering steel, and stainless steel. It would not be recommended to connect bare steel to galvanized steel, as the zinc will want to protect all of the carbon steel and the overall coating performance life will be decreased. However, if the other steel surfaces are painted or isolated with a non-conductive material, these connections will not significantly decrease the life of the galvanized coating as long as the paint or isolating materials are maintained over the coating lifetime.

When connecting galvanized steel to any stainless or weathering steel, there are other considerations. Under atmospheric conditions of moderate to mild humidity, contact between a galvanized surface and a stainless steel surface is unlikely to cause substantial corrosion. However, if the surfaces are in the presence of salt water or salt water air, it would be best to electrically isolate the two metals.

When connecting hot-dip galvanized steel to weathering steel, for instance using galvanized bolts on weathering steel beams, the zinc will initially sacrifice itself to protect the weathering material until the protective layer of rust patina develops. Once the rust patina is in place, it will prevent further sacrificial action from the zinc. So, when connecting the two metals, it is important to ensure the galvanized coating is thick enough to last until the rust patina forms, usually several years. Most hot-dip galvanized bolts will naturally have enough coating to withstand the years of rust patina development with only a minimal loss in coating life.

- HDG Steel & Bare Steel

- HDG will sacrifice itself to protect surrounding bare steel, leading to reduced longevity

- HDG Steel & Painted Steel

- Negligible decrease in HDG performance if paint maintained

- HDG Steel & Stainless Steel

- Minimal accelerated corrosion in mildly corrosive environments

- Isolation recommended for aggressive or marine environments

- HDG Steel & Weathering Steel

- HDG coating will initially sacrifice itself to protect weathering steel until weathering steel rust patina develop