ASTM A384 Recommendations

The design and fabrication of the product to be galvanized are the responsibilities of the designer and the fabricator. Practice ASTM A384 provides guidance on safeguarding against warpage and distortion for optimum hot-dip galvanizing and shall be complied with in both design and fabrication. The primary recommendations within ASTM A384 for bridge design are as follows:

Avoid Susceptible Thin Sheet Steels

Steel invariably contains internal stresses induced at the mill from rolling operations used to bring structures, plate, and sheet to the final thickness. The most commonly distorted members of assemblies are that of sheet or plate which is ¼-inch in thickness or less the lighter the gauge of the steel, the greater the risk of warpage or distortion. Oftentimes sheet or plate can be returned to a flattened state using a jig or by weighing the product down on a flat surface during the cool-down.

Minimize Internal Stresses Induced by Cold Working

To reduce or eliminate the potential for warpage/distortion due to cold working, bending should be performed at the largest acceptable radii to minimize local stress concentration and the design should be optimized to reduce punched holes, rolling, riveting, bending, and straightening. After galvanizing, these products should be air cooled (instead of quenched) to minimize induced stress from the cooling cycle. Where excessive cold working or tight bend radii cannot be avoided, the product should be stress relieved per the guidelines provided within ASTM A143, Section 6.

Optimize Welding Before Hot-Dip Galvanizing

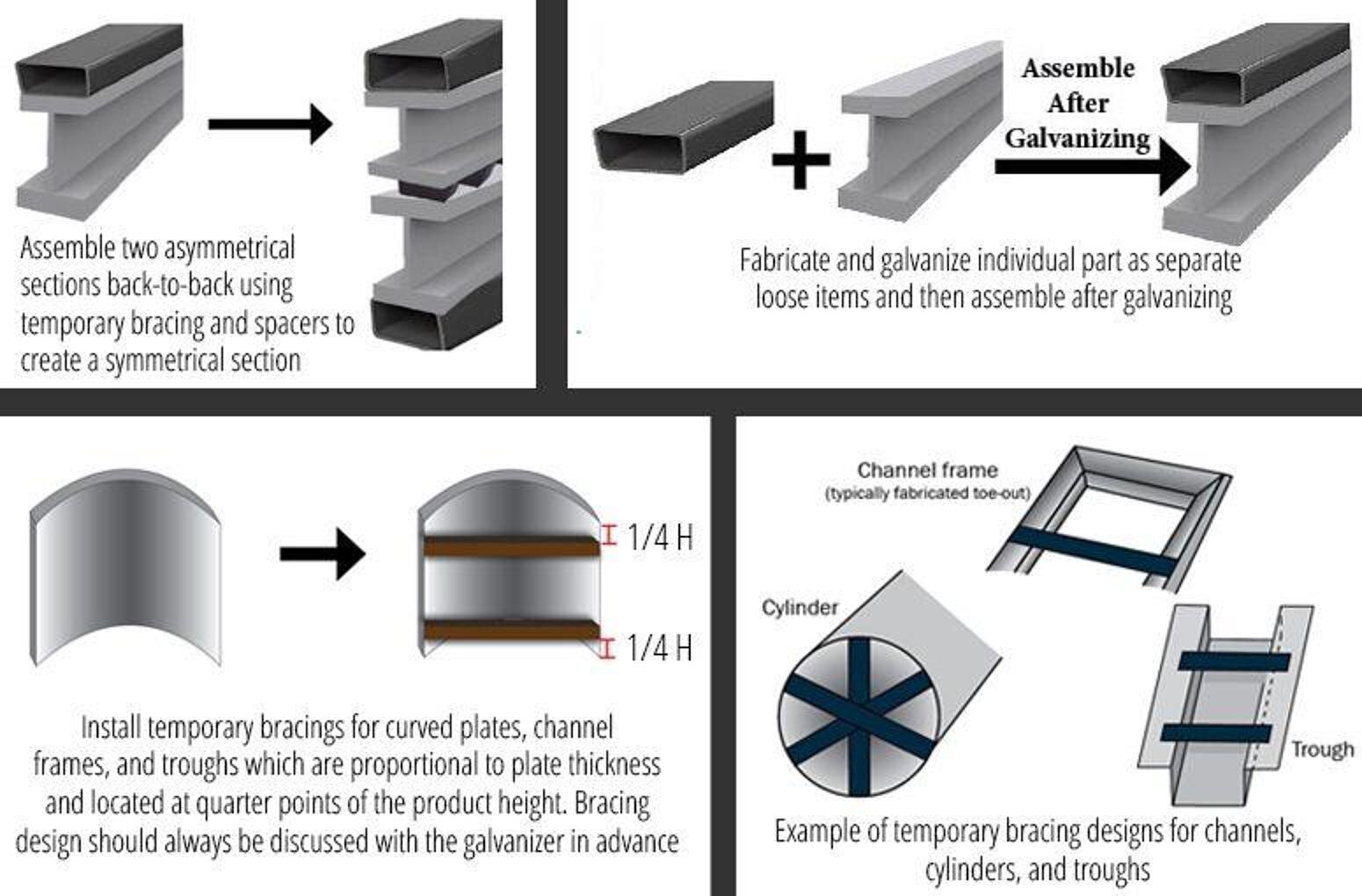

Welding results in significant residual stress in small areas of an assembly due to the extreme temperature differences experienced. All efforts should be made to keep the stresses in the construction as low as possible right from the beginning to enable the steel to absorb the internal stresses completely. The overall amount of welding can be minimized by using bolted connections or performing assembly after hot-dip galvanizing. Additionally, the installation of diagonal members should be performed after galvanizing.

Where welding before galvanizing cannot be avoided, the internal stresses in the connections can be minimized by avoiding joint designs or weld lengths which are greater than statically required, and by placing welds near to and symmetrically around the neutral axis - aligning welds so that shrinkage and opposing forces are balanced rather than all pulling in the same direction.

Asymmetrical Design

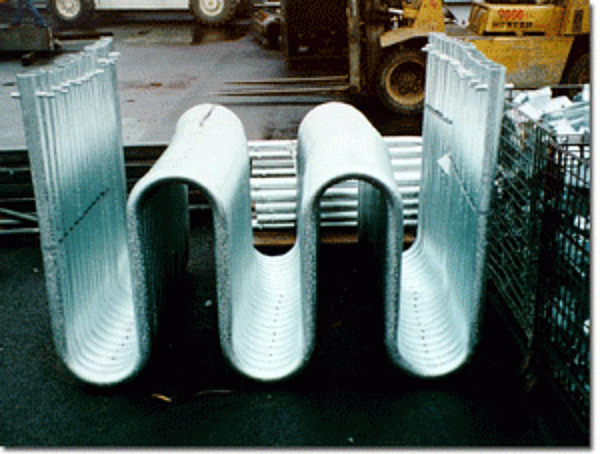

Symmetrical sections such as I-beams and tubing will be less likely to distort than asymmetrical pieces (camber beams, channels, tees, custom beams, girders) because the thermal expansion forces above and below the neutral axes balance each other. Furthermore, cylindrical structures are less likely to warp or distort than rectangular or elliptical ones. Conversely, the internal stresses in asymmetrical designs will be relieved unevenly due to the constraints of the materials shape. Specify symmetrically rolled sections instead of angle or channel frames. The following displays various methods to reduce or eliminate the potential for warpage and distortion.

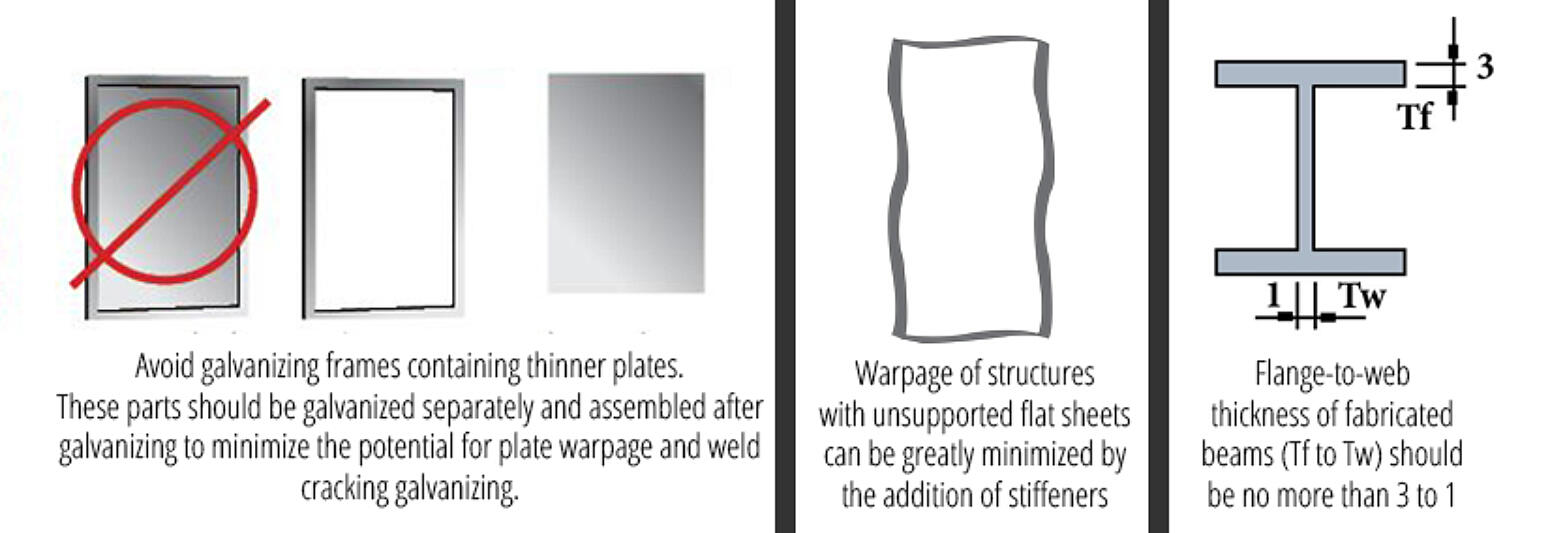

Minimize Thick and Thin Material in the Same Assembly

When two steels of different thicknesses are assembled and brought up to galvanizing temperature, the thinner steel heats up and expands more quickly than the thicker steel. If the thicker steel restrains the thinner steel from expanding freely, warpage/distortion of the thinner steel can occur. Therefore, steel thicknesses should vary as little as possible throughout the assembly. Uneven thickness at joints should be avoided along with the surrounding of thinner material with thick framing), unsupported flat sheet assemblies, and flange-to-web thickness ratios greater than 3 to 1 for fabricated beams . Wherever possible, galvanize thick and thin portions separately and join them after galvanizing.