Life-Cycle Assessment

To make a case for the sustainability of hot-dip galvanized steel, it is helpful to examine data produced when a life-cycle assessment (LCA) of a structure is conducted. Life-cycle assessment often called a "cradle-to-grave" study, is the study of the environmental impact of a process or product, and includes measurement of energy consumed and all emissions during raw material production and manufacturing of the final product through use and end-of-life (recycling/disposal).

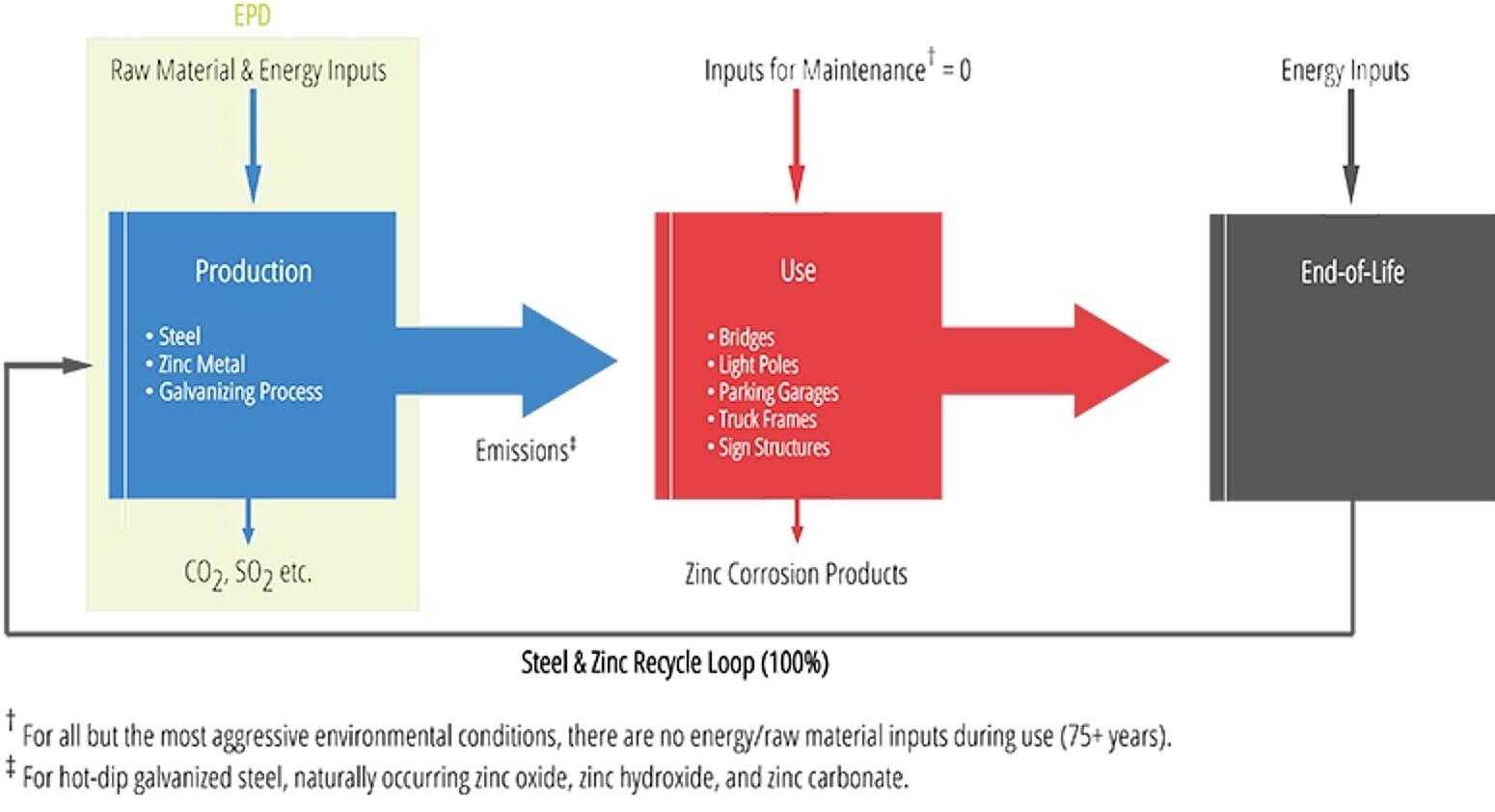

The AGA has worked with renowned sustainability practitioners Sphera to develop an industry-wide Environmental Production Declaration (EPD). The EPD tracks energy consumption and emissions during steel making and fabrication, zinc production and the galvanizing process. An EPD is equivalent to the production phase of a full life-cycle assessment (LCA) which AGA last had done by Five Winds in 2008. This chart shows an overview of the impact of hot-dip galvanized steel from production to end-of-life.

Production Phase

Long before galvanized steel is pieced together to form a parking structure frame, production begins on the steel and zinc metals. To begin, more than 95% of structural steel manufactured in the United States is fully recycled from previously used steel materials, making the initial environmental impact of using a steel frame minimal. By specifying a hot-dip galvanized zinc coating for corrosion protection, you are choosing to utilize yet another abundant, recyclable, natural metal to further the cause of sustainability, as well as protect your parking structure.1

The production phase for HDG includes the life-cycle inventories of steel, zinc, and the galvanizing process. All emissions, energy, and material usage for hot-dip galvanized steel are isolated to the production phase. As delineated in greater detail in the figure below, the initial environmental cost is the final environmental cost, because there are no environmental outputs in the use or end-of-life phases.

| Production Phase | PED * | GWP (CO2equiv.) | AP (SO2 equiv.) | POCP (C2H2 equiv.) |

|---|---|---|---|---|

| 1 kg of HDG Steel | 25.9 MJ | 1.80 kg | 0.00615 kg | 0.000824 kg |

| * 106 Joules (unit of energy) | ||||

Use Phase

The use phase is where hot-dip galvanized steel passes competitors in the race toward sustainability. After the steel pieces have been created, galvanized, sent to the site, and quickly assembled, there is nothing to do but wait. For 70+ years, galvanized steel will remain maintenance free - no raw material or energy expended, no carbon footprint extending beyond the production phase.

Conversely, a painted structure requires regular, routine maintenance - i.e., the entire painting process and all of its environmentally harming outputs must be repeated every 12-20 years. This means every decade or two, more paint chemicals and VOC's will be expelled into the atmosphere and made a permanent part of the waste stream. There are also indirect costs associated with this continued maintenance, including exhaust from transport vehicles and particulate emissions caused by surface-preparation blasting, not to mention the disadvantage to the community caused by maintenance shut-downs and delayed usage.

The table below provides the cost (or lack thereof) for HDG and identifies undetermined paint costs P1, P2, P3, and P4 during the use phase.

| Use Phase | PED | GWP (CO2 equiv.) | AP (SO2 equiv.) | POCP (C2H2 equiv.) |

|---|---|---|---|---|

| 1 kg of HDG Steel | 0 MJ | 0 kg | 0 kg | 0 kg |

| Painted Steel | P1 MJ | P2 kg | P3 kg | P4 kg |

End of Life Phase

The true beauty and sustainability of incorporating hot-dip galvanized steel into a parking structure is there really is no "end-of-life," only a return to production - cradle-to-cradle, rather than cradle-to-grave. At the end of its useful life, the steel framing system of a parking structure can be recycled into new structural steel for new buildings and other applications and the zinc captured for reuse in new coatings.1

In fact, steel is the most recycled material in the world. As indicated in the table below, LCA credits HDG steel with 8.61 MJ for every kilogram recycled. Utilizing hot-dip galvanized steel for corrosion protection reinforces the environmentally friendly nature of steel framing, as the zinc used in the coating is also 100% recyclable. In contrast, after years of environmentally damaging maintenance, a painted coating becomes a permanent part of the waste stream when it is put to rest.

Due to the LCA credit of 8.61 MJ/kg, resulting in a complete life-cycle primary energy use of 17.3 MJ, the complete life-cycle primary energy use for HDG steel is actually less than the primary energy used in the production phase. This, combined with the recyclability of the steel and zinc, means a hot-dip galvanized parking garage frame expends no extra energy or materials for the final phase and will be ready to continue on to a new phase of production.

| End-of-Life Phase | PED* |

|---|---|

| 1 kg of HDG Steel* | -8.61 MJ |

| * Steel is the primary component and is 100% recyclable, however, the zinc in the galvanized coating is also 100% recyclable. Paint on the other hand, becomes a permanent part of the waste system. | |

Complete LCA

Incorporating a framing system that uses natural, abundant earth materials completely recycled at the end-of-life stage is intuitively a more sustainable solution than applying chemically-based paint applications requiring decades of maintenance. Additionally, empirical, quantifiable LCA data indicates a hot-dip galvanized steel frame is an environmentally friendly, sustainable solution for a parking structure. The table below provides the results of the complete LCA.

With HDG steel, emissions, energy output, and material are isolated to the production phase. Because there are often no emissions or energy requirement for hot-dip galvanized steel during the use and end-of-life phases, the initial environmental cost is the final environmental cost. Not only that, but both the steel and the zinc used are completely recyclable, making the parking garage less harmful to the environment from cradle-to-cradle.

Though steel, the primary component of a steel framing system, is recyclable regardless of which corrosion protection coating is chosen, the environmental impact of that coating is significant as case studies have proven.

| Complete Life-Cycle | PED * | GWP (CO2equiv.) | AP (SO2 equiv.) | POCP (C2H2 equiv.) |

|---|---|---|---|---|

| 1 kg of HDG Steel | 17.3 MJ | 1.801 kg | 0.00615 kg | 0.000824 kg |

| * 106 Joules (unit of energy) | ||||

1 American Institute of Steel Construction (AISC). Innovative Solutions in Steel: Open-Deck Parking Structures.2003.