Construction Savings

Time Equals Money

From the very beginning of the project, using hot-dip galvanized steel members to construct a garage saves money. Simple, uncomplicated steel structural frame designs take less time to develop and are less costly. Pre-fabricated and galvanized offsite, the steel members move quickly through production.

Because the fabrication and galvanizing processes are performed at indoor facilities, items move right down the line to completion with no hindrances due to inclement weather. The pieces are then loaded and delivered to the site ready for construction. When time equals money, a quick production phase puts money back in your pocket.

Lighter Load, Smaller Charges

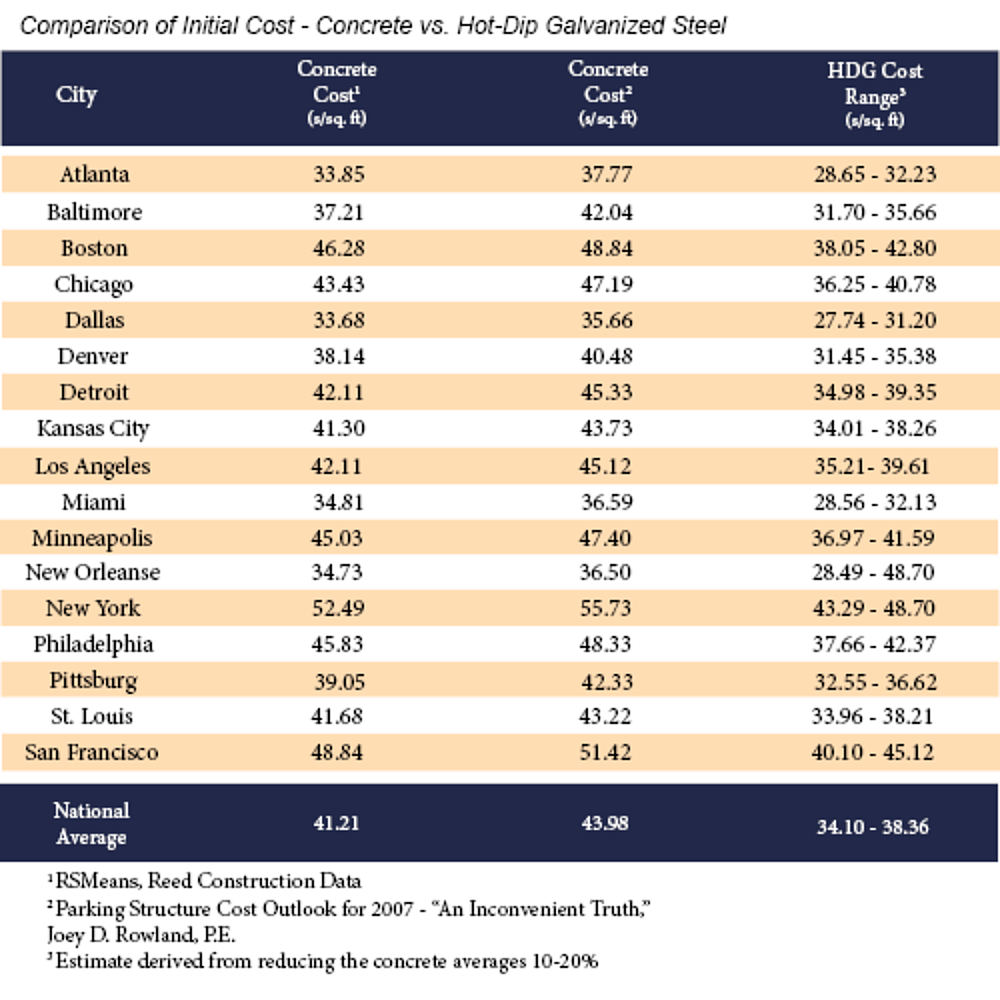

Because steel beams are considerably lighter than heavy, unwieldy precast concrete elements, transportation costs are significantly less as well. Less tonnage loaded onto trucks, train cars, or barges translates into a smaller transportation price tag. Once delivered, lightweight building materials will reduce onsite crane requirements - no special maneuvering equipment required. Additionally, less weight often means fewer and smaller diameter caissons are required. With all of these savings combined, steel-framed systems can typically be constructed with a cost savings of 10 - 20% over a concrete alternative.1 Figure 5 is a comparison of initial costs for both concrete and hot-dip galvanized steel construction applications.

1 American Institute of Steel Construction (AISC). Innovative Solutions in Steel: Open-Deck Parking Structures. 2003.