Availability, Efficiency, Safety

Hot-dip galvanized (HDG) steel is readily available. Many corrosion protection methods depend on proper temperature and humidity conditions for correct application. However, because hot-dip galvanizing is a factory controlled process, it can be accomplished 24/7/365 rain or shine. Zinc solidifies upon withdrawal from the bath, so there are no delays for curing; and galvanized steel could realistically be galvanized, shipped to the site, and erected on the same day. On the other hand, if the galvanized material does not need to be installed immediately, it is easily stored outside, as UV rays do not degrade the coating's integrity.

Abundant Materials

As North America continues to strive for sustainable development, the same thinking should be applied to the materials used in construction. Another characteristic of zinc, making it ideally suited for many jobs is its abundance. The main materials used in the galvanizing process, zinc and steel are common; in fact, zinc is the 24th most abundant material in the earths crust, and iron is the 4th. Zinc and steel are also both 100% recyclable without the loss of any chemical or physical properties - steel is the most recycled material in the world.

Zinc is a natural element found in air, soil, and water. Approximately 5.8 million tons of zinc are cycled through the atmosphere annually through natural phenomena. Zinc is also common and essential to life. Zinc is found in a number of products we use daily such as cosmetics, tires, cold remedies, baby creams to prevent diaper rash, treatments for sunburns, and sunscreens. In fact, zinc oxide blocks more UV rays than any other single ingredient used in sunscreen. Furthermore, we all require zinc to live as it helps with regular functions such as vision, reproduction, digestion, and breathing.

Efficiency & Safety

Furthermore, because of hot-dip galvanized steel's durable, maintenance-free nature, elements can be stockpiled outside for years without compromising the zinc coating and its corrosion protection. The zinc coating of HDG is unaffected by UV rays, extreme temperatures, rain, snow, or humidity, so with proper storage, it is simple to keep an inventory on-hand for quick replacement in an emergency. Stocking frequently used parts until they are needed saves time, and if bought when prices are low, saves money.

Because concrete is a porous material, corrosive elements will inevitably seep deep into the exposed concrete, eventually reaching the rebar within. If left unprotected, the steel will begin to rust, creating corrosion products 2-10 times more voluminous than the original steel. The volume of these corrosion products will begin to create stress that exceeds the tensile capacity of the surrounding concrete, causing it to crack and spall. This can be dangerous for the vehicles, pedestrians, or wildlife below, and can weaken and compromise the stability of the concrete structure. Hot-dip galvanized reinforcing steel eliminates the risk of spalling because the zinc corrosion products are less voluminous and migrate away from the bar into the matrix of the concrete. The migration alleviates the potential for increased pressure, thus eliminating the risk of spalling.

Case Study

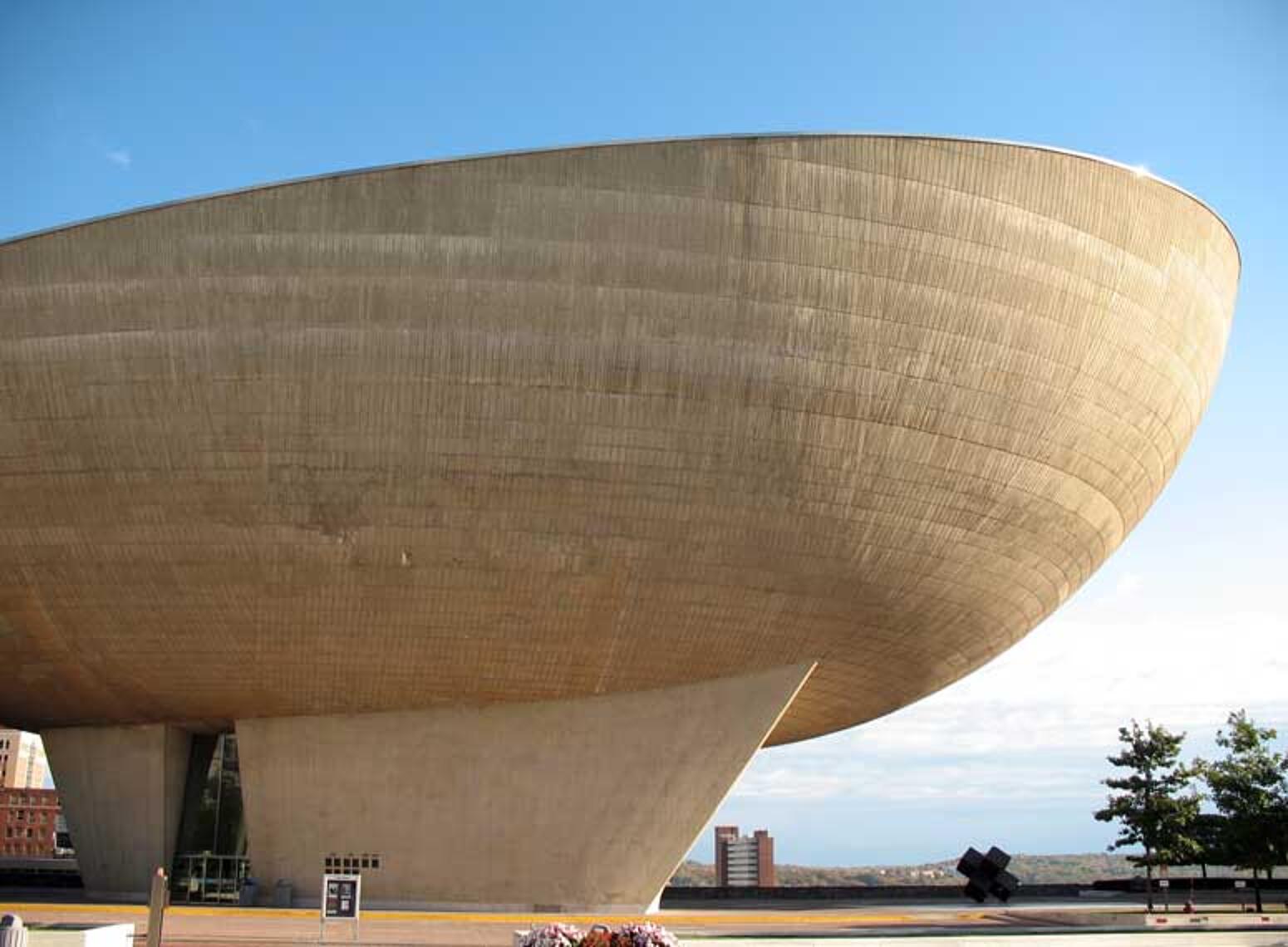

The Egg- Albany, NY, 1978

The Egg at the Empire Center Plaza in Albany, NY, was completed in 1978. The performing arts center was a massive undertaking of architecture, combining aesthetics and function in a concrete and steel form. The concrete and steel stem of the structure extends six stories into the ground. The Egg keeps its shape by wearing a girdle comprised of a heavily reinforced concrete beams utilizing hot-dip galvanized rebar.

The superior durability and corrosion protection of hot-dip galvanized steel made it the logical choice for the reinforcement of the concrete in such an integral factor of the structure's design. The reinforced girdle helps the egg keep its shape and directs the weight of the structure onto the supporting pedestal and stem. Housing two theaters, the building's curved exterior is continued on the interior. The walls are not square with harsh corners, but rather curve even up to meet the concave ceiling to give an appearance of endlessness and improved acoustics. Thanks to hot-dip galvanized reinforcing steel, The Egg's extravagant design has not only wowed citizens and visitors for decades, but it will remain a beautiful centerpiece of Albany for generations to come.