Aesthetics

Aesthetics are important to nearly every construction project. Whether an attractive, artfully designed sculpture or architecturally exposed steel element, or bridge, bus station, or other infrastructure element, galvanized steel offers design flexibility, and an attractive, natural gray finish or if color is desired it can be easily painted or powder coated.

Modern, Natural Appearance

For some galvanized steel projects, such as electric substations, solar panels, or rail line infrastructure, the goal is often to blend seamlessly with the surroundings. As galvanized steel weathers and the zinc patina forms, the coating becomes a uniform matte gray. Whether in rural, wooded areas that are wildlife sensitive or in the city where non-reflectivity is important, the natural, non-intrusive finish of hot-dip galvanizing compliments and blends in with any environment.

In addition to providing a natural, blendable appearance, utilizing hot-dip galvanizing on architecturally exposed structural steel (AESS) provides visual peace of mind the steel is in good condition. AESS elements are often designed to be centerpieces and talking points of steel construction.

The high strength-to-weight ratio and ductility of steel allows for curves, arches, and intricate patterns and designs when planning AESS elements. However, when AESS elements are exposed to the atmosphere, it is important to ensure they remain beautiful design elements by protecting them against corrosion. Hot-dip galvanized AESS elements can fight corrosion for decades without stifling your design freedom.

HDG and AESS

ASTM A123 is written to ensure corrosion protection and longevity, not necessarily to maximize aesthetics of HDG. Hot-dip galvanizing's initial coating appearance can vary, so if maximizing aesthetics is important for your project, it is recommended to have communication upfront with the fabricator and galvanizer about the intent to use AESS and discuss additional design/fabrication details to encourage a more aesthetic finish.

Aesthetics Case Study

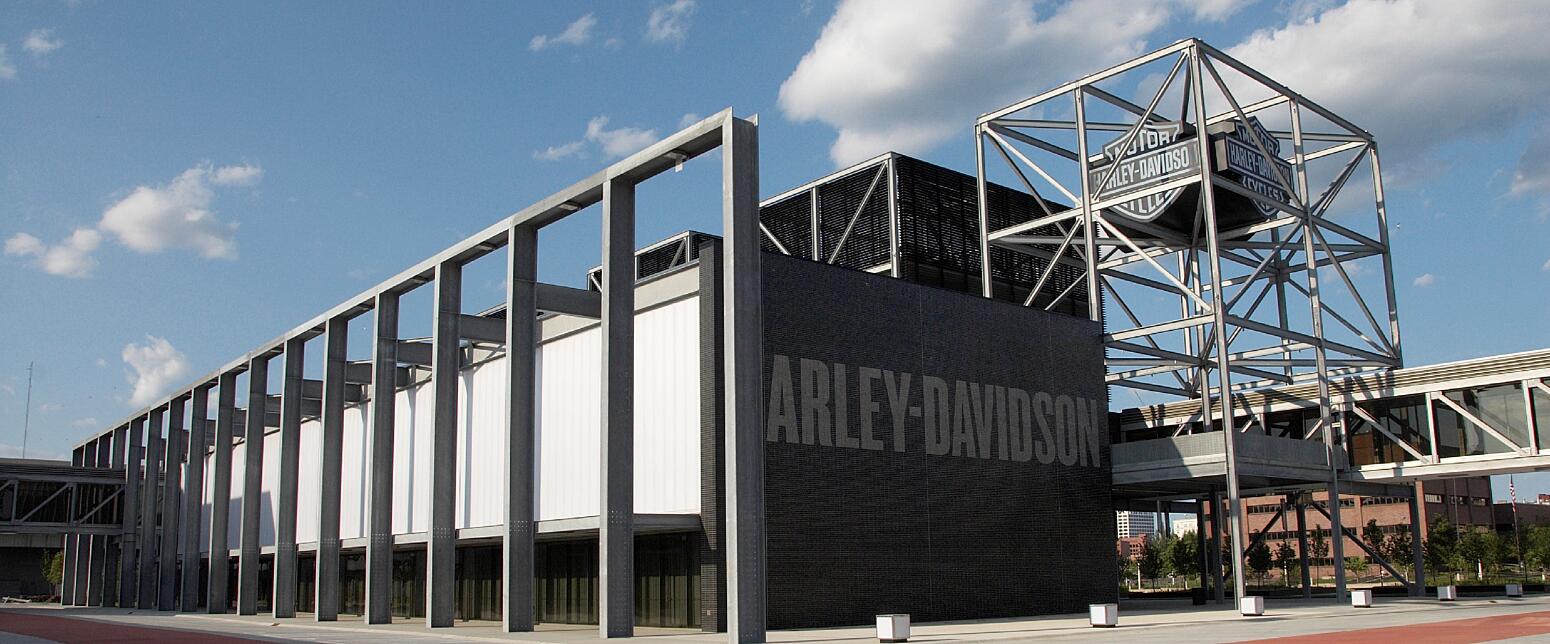

Harley Davidson Museum - Milwaukee, WI 2008

One can almost hear the ripping, throaty roar of a Harley Davidson motorcycle upon viewing the industrial, frank steel structure of the Harley Davidson Museum in Milwaukee. A steely, modern tribute to this American icon, the 130,000 square foot museum is located on the shores of the Menomonee River on a 20-acre reclaimed industrial site.

Rather than find a decorative skin for the buildings comprising the museum, the designers turned to the motorcycles themselves for inspiration. Durability, long-life, quality hot-dip galvanized steel encompasses all of these ideals, making it the natural selection to serve as an honest representation of the elements of Harley Davidson engineering. The architecture of the museum reveals exposed I-beams, columns, gusset plates and cross bracing, all open to the harsh effects of sun, snow, and rain. Hot-dip galvanized steel will withstand these tough elements, providing maintenance-free protection from the damaging effects of corrosion, both structurally and aesthetically.

With 2.5 million pounds of steel galvanized, good communication between the designers, fabricator, and galvanizer resulted in a smooth process with a quality product. Quick turnover and enormous savings compared to rendering the same look with paint sweetened the deal, as well. Now, this $75 million galvanized structure will stand as a durable, corrosion-free homage to Harley Davidson history, culture, and engineering.

Duplex Systems

The natural, matte gray finish does not suit every project of every specifier as sometimes color is preferred or needed for branding, safety marking, etc. However, by specifying a duplex system galvanizing your project and then painting or powder coating over to the desired color ensures you dont have to sacrifice the corrosion protection benefits and extended maintenance of HDG steel.

Duplex systems provide more benefit than just aesthetic options. The combination of hot-dip galvanized steel and paint or powder coating provide a synergistic effect. The paint/powder extends the life of the coating by providing an additional barrier coating to the zinc layers, while the galvanized steel prolongs the life of the paint coating by preventing underfilm corrosion and peeling.

The result of the two coatings working in synergy is extended corrosion protection. The service life of a duplex system is 1.5 to 2.3 times the sum of the individual systems. For example, if the life of the galvanized coating in a particular environment is 70 years, and the expected life of the paint is 10 years, the expected life of the duplex system would be at least 120 years (1.5 x (70+10)).

This extended service life assumes no maintenance will be done to keep the paint or powder coating intact. Realistically, if someone invests the premium cost upfront for a duplex system, they likely plan to keep the color on the structure. So, in practical terms, the synergistic effect of utilizing a duplex system is the extended maintenance cycle it provides. With hot-dip galvanized steel as a primer, the time to first maintenance of the paint or powder coating is extended 1.5 to 2.0 times what it would be for bare steel. The AGAs publication Duplex Systems: Painting Over Hot- Dip Galvanized Steel and instructional DVD guide Preparing Hot-Dip Galvanized Steel for Paint provide more information on specifying duplex systems.

Duplex Case Study

Verele Japanese Restaurant – Anantara Peace Haven Tangalle Resort - Tangalle, Sri Lanka 2017

Verele Japanese restaurant lies at the western-most end of the Anantara Peace Haven Resort Tangalle, overlooking the Indian Ocean. This restaurant on the beach consists of two dome-shaped structures resembling two huge balls. Teppanyaki-inspired dining is enriched by the unique flavors of Sri Lankan cuisine at this specialty beachside restaurant. Because of its location, a duplex system of hot-dip galvanizing and paint was specified to protect these structures from the harsh marine environment and tropical weather of the southern coastal region.

If these structures were painted only, periodic maintenance cost would be much higher due to the rapid rate of corrosion in this high chloride environment. Similarly, adding the additional protective paint coating to hot-dip galvanizing will increase the service life of the galvanizing in this environment.

Anantara Peace Haven Resort is highlighted by this unique restaurant and it is a wonderful tourist attraction. Many tourists enjoy food with the sea view from this restaurant and hot-dip galvanized steel played a major role in making that possible in a cost-effective manner.