Menu • Quick Links • Search

Login

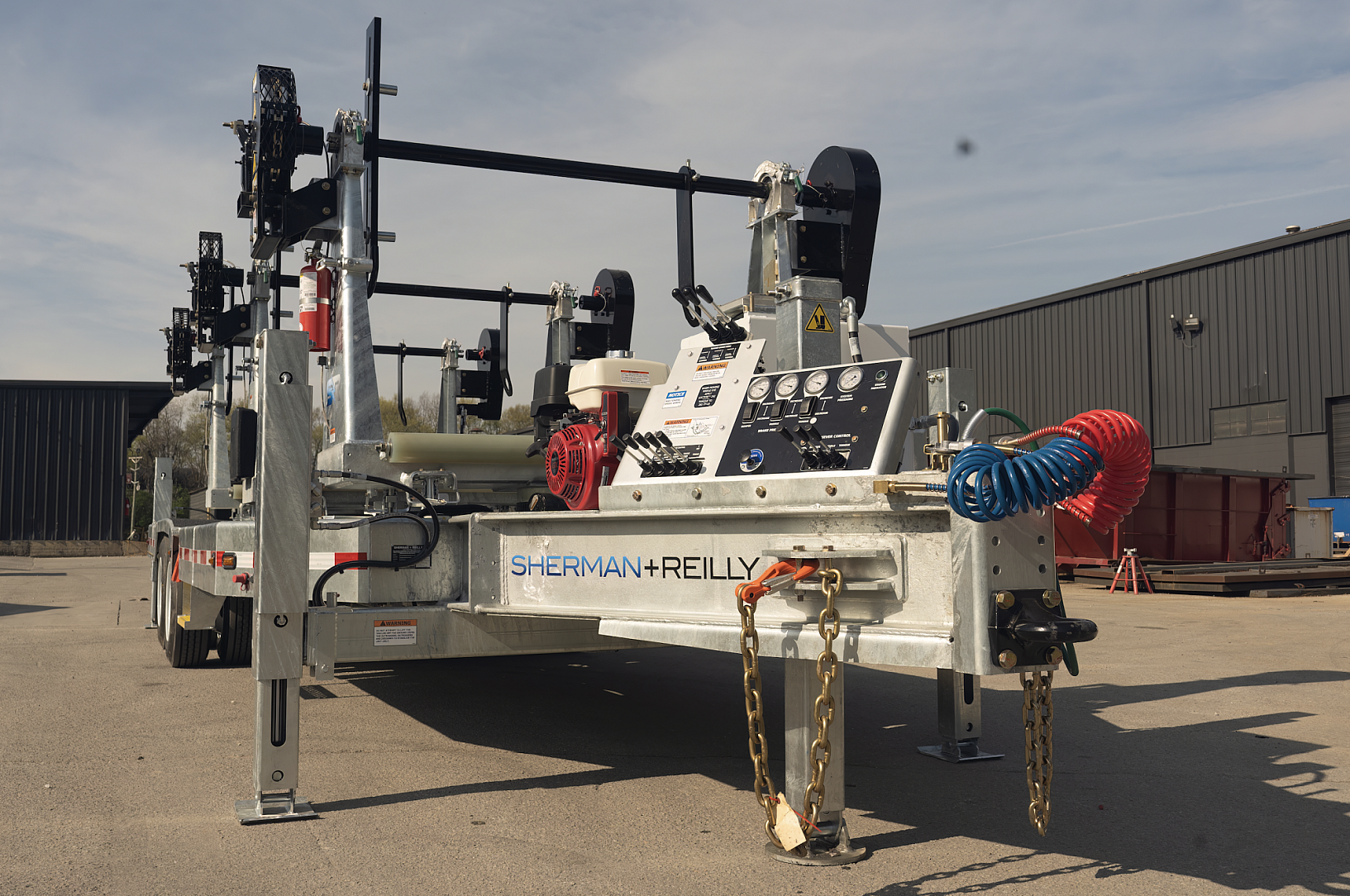

CloseIn the heart of Chattanooga, Tennessee, a visionary project took root. Guided by Sherman+Reilly, a plan to galvanize a large trailer was underway. The project not only aimed to set an entirely new standard within the industry, but also prove the effectiveness and strength of hot-dip galvanizing. In stark contrast to conventional paint systems that would gradually scrape and corrode with time, the galvanizing process proved to be the perfect answer for the longevity of the customer’s trailers.

Hot-dip galvanized trailers have become a core competency for Tier 1 Sherman+Reilly customers as they count on the structure to stand up to weathering and corrosion over time.

At its core, the customer sought a coating protection system that would withstand the harshest conditions while ensuring the utmost safety for utility workers. The project encountered a crucial crossroad—how to shield the utility trailer from corrosion without compromising its performance. The answer lay in the power of hot-dip galvanizing. Its ability to handle the elements while requiring no maintenance overtime meant that the customer could count on its performance over using a paint system. Hot-dip galvanized trailers have become a core competency for Tier 1 Sherman+Reilly customers as they count on the structure to stand up to weathering and corrosion over time.

Beyond its immediate impact, the Sherman+Reilly project cast ripples of transformation. It proved the ability of galvanizing to tackle challenges tied to size, intricacy and weight management.

The galvanizer was able to partner effectively with the customer to turn an ambitious vision into a reality. The utility trailer’s grand proportions demanded careful handling during the hot-dip galvanizing process. The weight factor also became a central concern, pushing the engineering team to collaborate closely with the galvanizer to overcome the obstacles of lifting the larger pieces.

To make sure the vent and drain holes were placed correctly, the galvanizer used 3D modeling, making the process more efficient. This partnership between customer and galvanizer allowed the project to work together seamlessly from conceptualization to construction.

In the end, the Sherman+Reilly Trailer project wasn’t solely about a utility trailer; it encapsulated the spirit of ingenuity and cooperation. The trailer can expect to be used for decades down the road because of the decision to galvanize over paint methods, and will work safely for the linemen that use it most.

Details

Award Class

Newly Complete

Award Sectors

Original Equipment Manufacturing

Environment

Industrial/Urban

Location

Chattanooga, TN United States

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Prior HDG Experience, Quality of HDG

Components Galvanized

All steel components were galvanized.

Tonnage/Size

Steel: 4

HDG: 4

Team Members

Engineer

Daniel Landgraf

Sherman-Reilly

Member Galvanizer(s)

Valmont Coatings - Birmingham Galvanizing

Thank you! Your vote has been accepted.