Menu • Quick Links • Search

Login

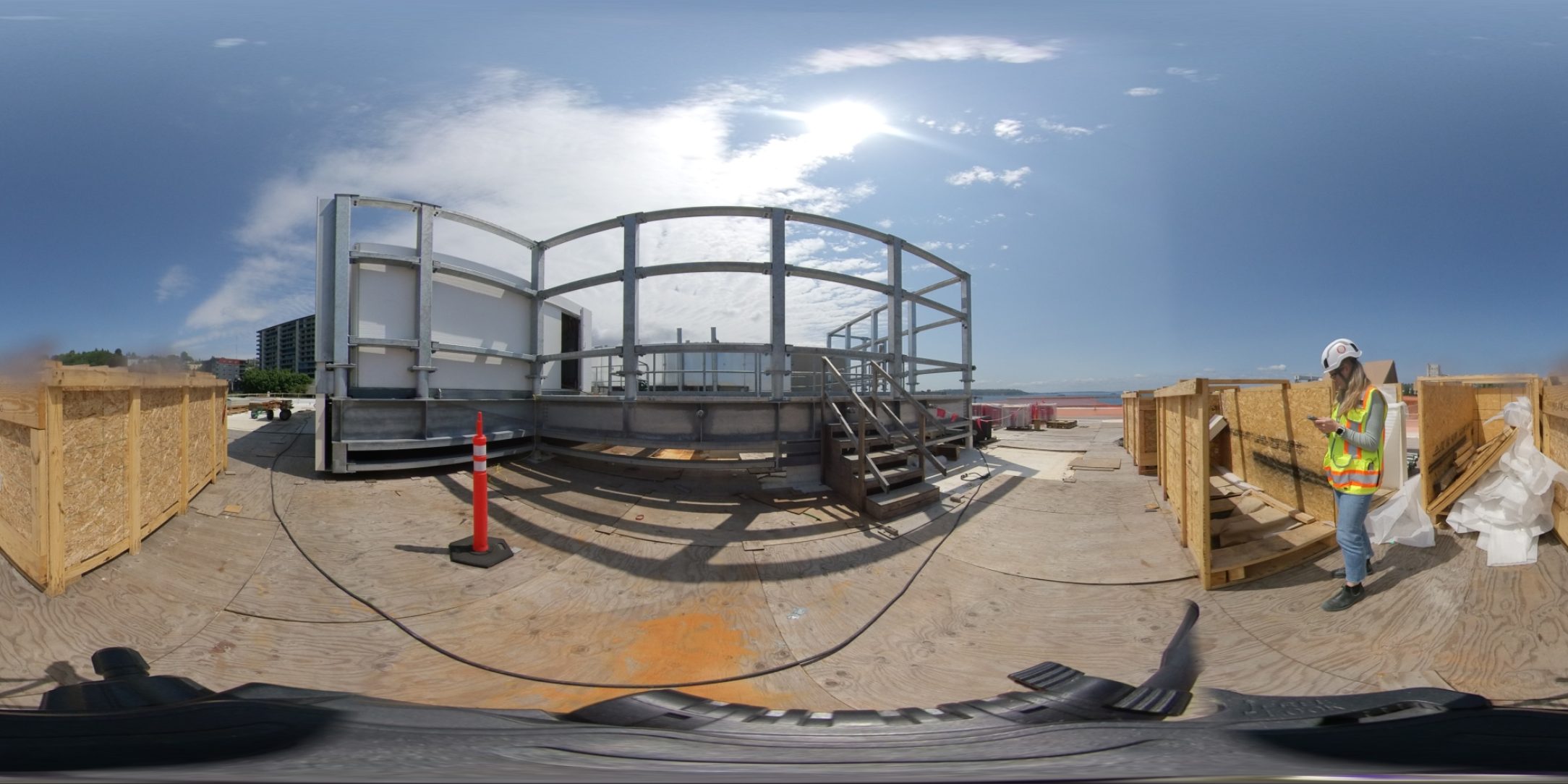

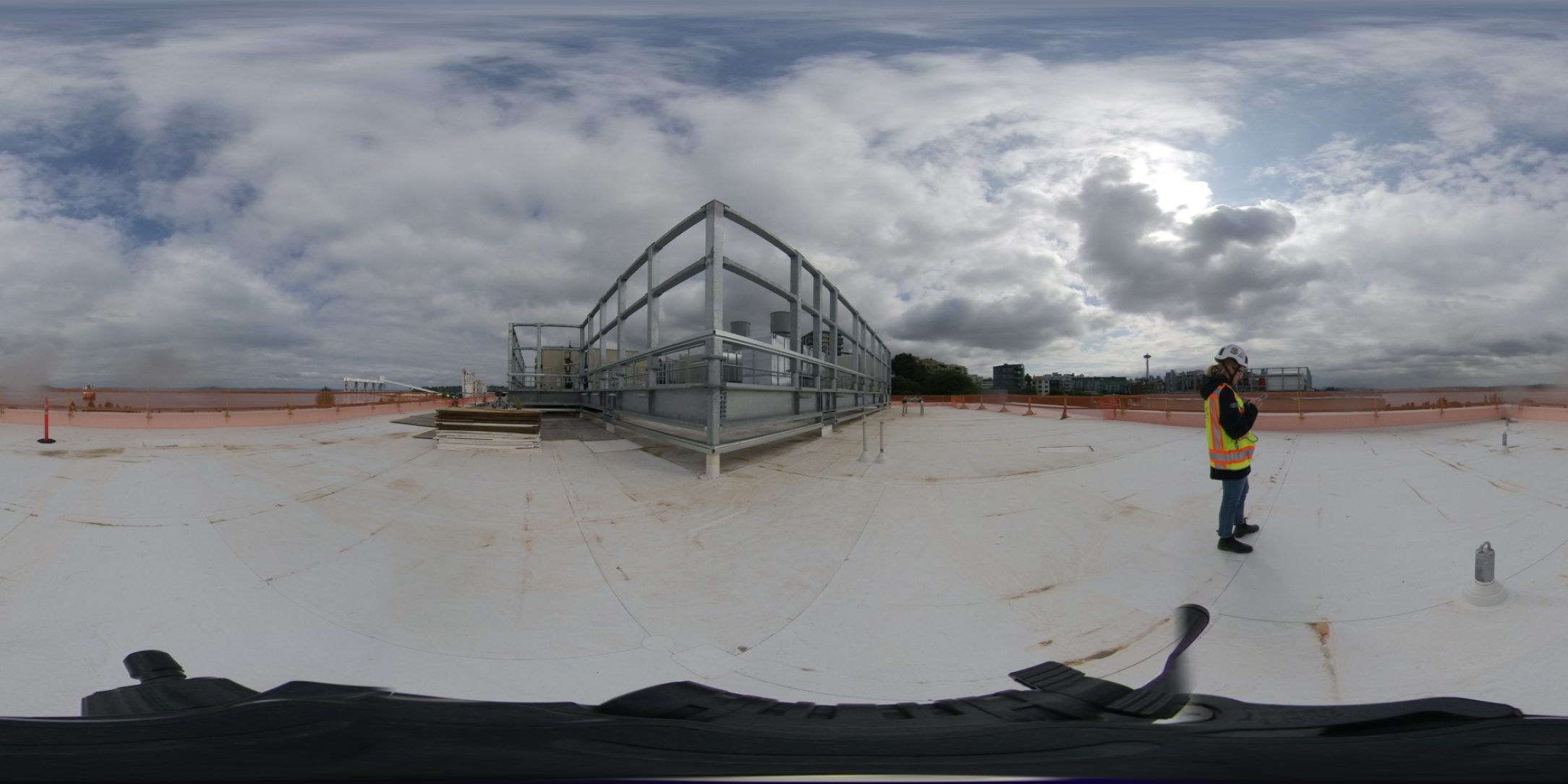

CloseThe RMR Unison project was an ambitious undertaking, involving the transformation of two pre-existing office buildings into versatile spaces accommodating both office and laboratory functions. The existing structures, initially designed for housing mechanical equipment, were insufficient for the new rooftop equipment required for this retrofit. The solution demanded a substantial structural steel frame and platform to support the larger, modern equipment adequately.

Galvanized steel was a major defining feature of work for the RMR Unison project, and its successful delivery had major schedule implications. The final product arrived and allowed others to complete their scopes of work on project schedule, and the entire lot showed zero defects and is built to last as the owner and architect intended.

Situated less than a mile from Puget Sound, WA with the open expanse of the coastline stretching out to the West, the project faced the relentless and challenging Pacific Northwest weather conditions. The architects and engineers recognized the need for a durable, long-lasting solution. The choice was clear; hot-dip galvanizing for the steel platform was the answer to the corrosive elements and climatic challenges, ensuring a resilient and enduring structure. An impressive 303 tons of steel formed the backbone of the structure, and the entire project was hot-dip galvanized for protection.

The RMR Unison project holds the potential to be a transformative force in the community. As business buildings are repurposed into cutting-edge research spaces, it opens the doors for pioneering advancements in life science technology. These labs will be incubators for innovation, empowering entrepreneurs to develop discoveries that could revolutionize modern medicine.

Not only does the project impact the surrounding community, but it also holds immense importance because of its groundbreaking venture for the West Coast area. Even through the unpredictability of COVID-19, the project moved forward until completion in 2023. By revitalizing the waterfront business sector, the project contributes to the expansion of businesses in the area, breathing new life into the surrounding neighborhoods and communities.

The challenges posed by this project were handled through the partnership formed between the galvanizer and the customer. The project involved the intricate task of raising and bolting equipment to the roof, all while ensuring the structural integrity and longevity of the entire complex. No other coating protection system would be able to withstand the possible impact of lifting the components to these heights. Engineering and designing the support structure for the rooftop equipment demanded constant adjustments and modifications. A strong partnership between the galvanizer and customer allowed for fluid communication throughout the changes and produce a quality product that the city of Seattle would be proud of.

The RMR Unison project stands as a testament to the remarkable advantages of galvanizing versus paint, and it will continue to preserve the structural integrity of the building for generations to come.

Details

Award Class

Newly Complete

Award Sectors

Industrial

Environment

Industrial/Urban

Location

Seattle, WA United States

Reasons for Galvanizing

Coating Durability, Corrosion Performance, Life-Cycle Cost

Components Galvanized

Rooftop Structural Supports and Platform

Tonnage/Size

Steel: 303

HDG: 303

Team Members

Fabricator

Jason Welcome

Steelkorr

Architect

Perkins + Will

Member Galvanizer(s)

Valmont Coatings - Pacific States Galvanizing

Thank you! Your vote has been accepted.