Menu • Quick Links • Search

Login

CloseWhen considering all paint options, powder coating was the initial choice that left the customer frustrated in its long-term performance. Only after a short time, the coating would simply scrape or flake off. Galvanizing stood above the rest due to its ability to protect from harsh environmental conditions that would face the surveillance systems day in and day out. Hot-dip galvanizing not only enhanced aesthetics but also proved to be an affordable, cost-effective, and durable solution that aligned with the customer’s economic considerations.

Galvanizing stood above the rest due to its ability to protect from harsh environmental conditions that would face the surveillance systems day in and day out.

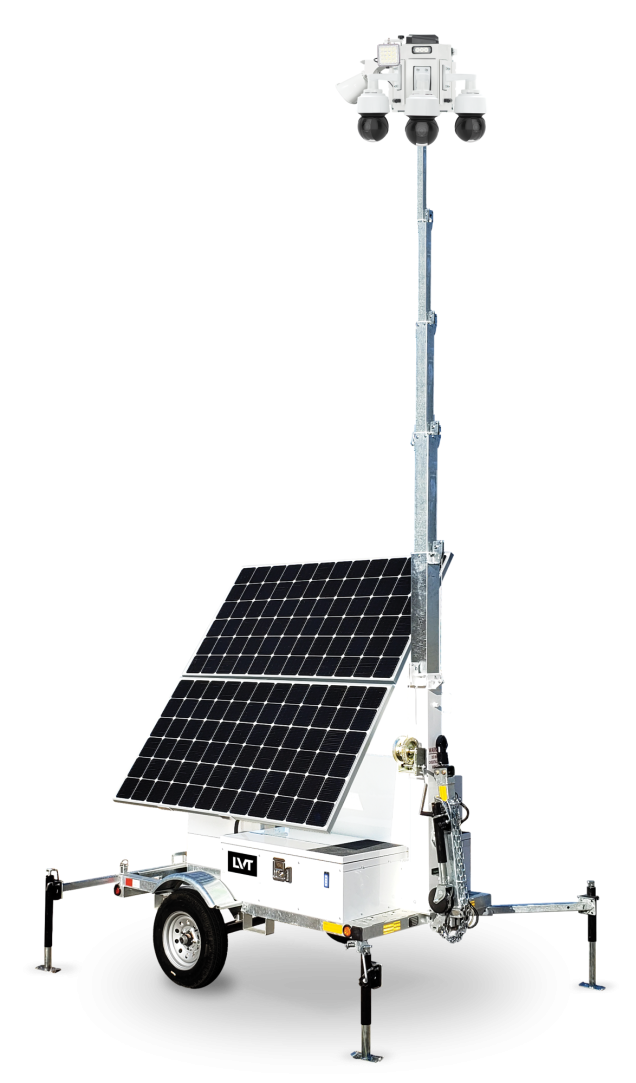

The trailer frames, fenders, 2-5” masts, solar array assemblies, mounts and wing assemblies underwent hot-dip galvanizing, ensuring superior durability, appearance, and long-lasting corrosion protection. This decision was particularly vital as many of the units were deployed along highways where durability is paramount.

Throughout the course of the project, there were challenges that required the customer and galvanizer to strategize and execute a plan that would be effective for both teams involved. Drainage needed to be executed in a specific manner to ensure smoother surfaces in certain areas. LVT addressed the challenges of vent and drain hole locations with the galvanizer, learning and adapting as the project moved forward.

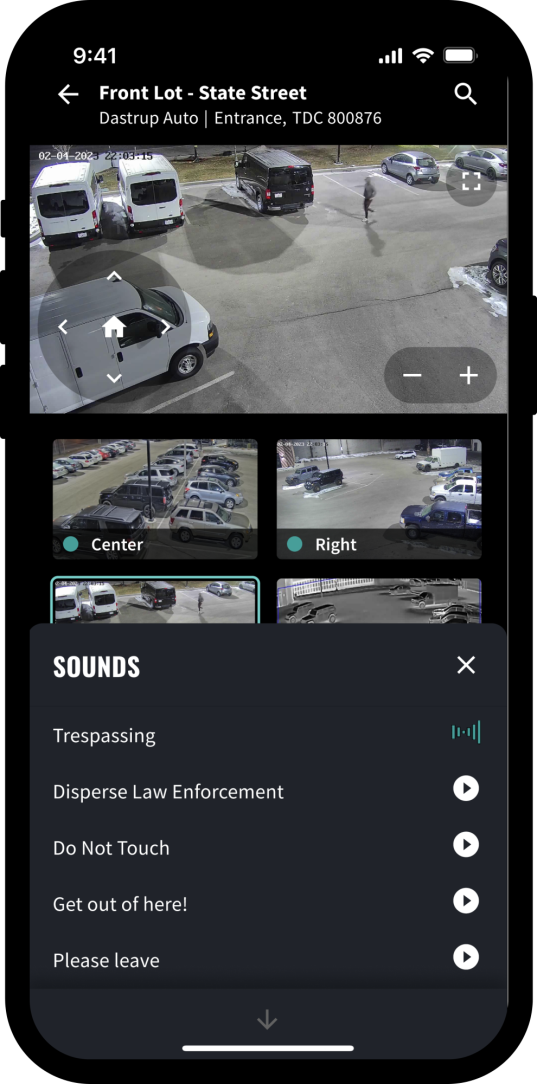

The project's uniqueness lies in its rapid deployment capability, pioneering features, and its revolutionary two-way communication with people on the ground. Incorporating advanced analytics, LVT can perform tasks without relying on human intervention. The ability for LVT to deploy surveillance systems same day and within a very short time frame meant that the galvanizer would need to maintain fluid communication, meet all project deadlines and provide a quality product that the customer would be proud of.

The profound impact of this project on the community is undeniable. A recently conducted study in which 60 LVT units were deployed across two towns revealed staggering results. Notably, there was a remarkable 40% decrease in shoplifting. The project's effect on public safety, as evidenced by various statistics, underscores its value in enhancing community well-being and security. LVT play a pivotal role in making communities safer, leading to positive outcomes and the resolutions of criminal cases due to its modernized technology, contributing to a better future for all.

LVT continues to gain traction in the industry, spanning across multiple industries including public services, law enforcement, hospitals, higher education, and more. Catering to a diverse range of sectors, the galvanizer was able to partner with LVT in their versatile solution for protecting the communities where people work and play.

The galvanizer played a pivotal role in this project, offering a convenient partnership in proximity and in quality. Their expertise in hot-dip galvanizing included instructions for vent and drain hole placement was invaluable. Throughout the entire design and fabrication process the collaboration ensured a safe and successful galvanizing process, preserving the project for generations to come.

Details

Award Class

Newly Complete

Award Sectors

Original Equipment Manufacturing

Environment

Suburban

Location

American Fork, UT United States

Reasons for Galvanizing

Aesthetics, Coating Durability, Corrosion Performance, Life-Cycle Cost, Quality of HDG, Sustainability, Turnaround Time

Components Galvanized

Trailer Frames and Fenders, 2-5” Masts, Solar Array Assemblies and Mounts, Wing Assemblies.

Tonnage/Size

Steel: 1712

HDG: 1712

Team Members

Owners

Derek Boggs

Live View Technology

Tom Aiello

Live View Technology

Member Galvanizer(s)

Valmont Coatings - Intermountain Galvanizing

AZZ Galvanizing - Reno

Thank you! Your vote has been accepted.