Menu • Quick Links • Search

Login

CloseFor twenty years San Francisco was thinking of creating a new transit center that would bring together 11 transit systems including Greyhound buses, Amtrak trains and connecting to eight counties and points beyond. The Transbay Transit Center met these goals and more.

Fred Clarke, founding partner at Pelli, Clarke, Pelli Architects, described the transformational project as “a transit-oriented development on a scale that we have not seen before in the United States.”

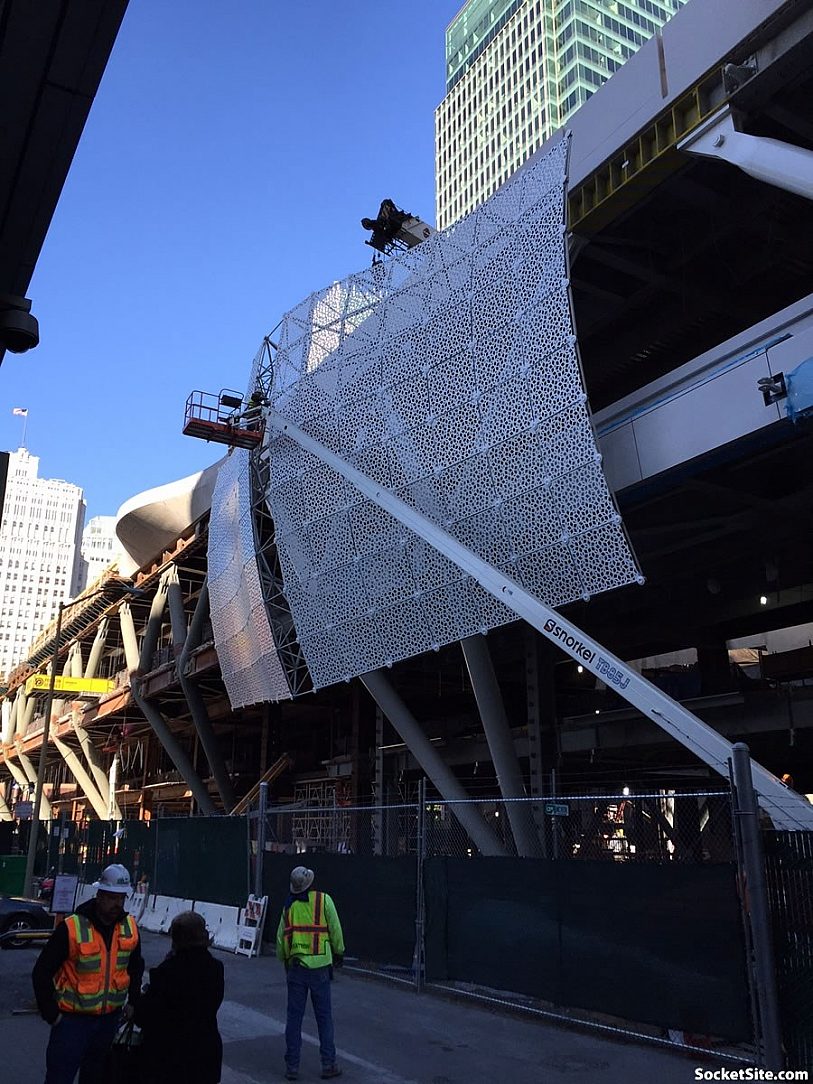

Dubbed the “Grand Central Station of the West”, the Transbay Transit Center each year will see 45 million travelers pass through the white lace-like façade. The powder coated white galvanized tubes that connect the perforated white wavy panels will last for generations without maintenance. That maintenance would otherwise cause disruptions for those many travelers. Every piece of tube was expedited with just a few days for galvanizing to meet a demanding construction schedule. After eight years of construction, with a total budget of $2.1 billion, with a rooftop park, future connections to high speed rail to Los Angeles and being a current bus and rail hub, this project is the crown jewel of a transit-oriented downtown neighborhood that has reshaped this world class city’s skyline.

Taking in to account the life cycle cost of hot dip galvanizing, this project was built to last. Any travel disruptions due to repairs needed to be kept to a minimum. This very high visibility site in the heart of one of the world’s great cities led DSI Spaceframes, Inc. to also secure the new Los Angeles Stadium at Hollywood Park project. The stadium will be the new home of the NFL’s Rams and Chargers. Galvanizing has also been specified in that project which has plans to open in 2020. San Francisco and the state of California have always been leaders in being “green”. With sustainability being a big factor, the choice of hot dip galvanizing was a perfect fit.

With the need for keeping San Francisco’s main transit hub going and being down for repairs to any part of the structure, hot dip galvanizing was the right answer. The Transbay Transit Center, with some help from hot-dip galvanizing, will provide daily commuters and worldwide tourists with a simple, elegant way to get in, out and around the “Paris of the West”.

Details

Award Class

Newly Complete

Environment

Industrial/Urban

Location

San Francisco, CA United States

Reasons for Galvanizing

Corrosion Performance, Initial Cost, Life-Cycle Cost, Sustainability

Components Galvanized

Approximately 1.1 million pounds of connector pipes that held aluminum 3,992 perforated white panels to create a wavy, undulating skin around the transit terminal.

Tonnage/Size

Steel: 24,000

HDG: 550

Team Members

Architect

Fred Clarke-Founding Partner

Pelli Clarke Pelli Architects

Fabricator

Josh Chambers-President

DSI Spaceframes, Inc.

Other

General Contractor

Webcor-Obayashi

Owner

Transbay Joint Powers Authority (TJPA)

Transbay Joint Powers Authority (TJPA)

Member Galvanizer(s)

AZZ Galvanizing - Joliet

Thank you! Your vote has been accepted.